RE: MMU2S filament tips on unload

Finally I solved the problem with my PLA multicolor prints by changing the extruder PTFE-tube.

Like oliver-r4 wrote the tube was bigger. (The outer diameter was 4.10 mm and the inner diameter was 2+ mm)

Thank you all for the help and the passion to solve problems. 😊

RE: MMU2S filament tips on unload

Glad to see that we cloud help 🙂

RE: MMU2S filament tips on unload

@michael-t66

Thank you for the explanation. I tried a couple experiments to see if additional fans would help.

According to my IR laser thermometer, the E axis stepper motor case temperature during a print was 32 C. The bond gear was 26 C, but I'm not sure how reliable the measurement was, since the gear was moving.

I ran a print with a 90mm fan balanced on top of the LCD assembly pointing at the E axis assembly. The stepper motor case temp dropped to 26 C. But, the filament tip shape did not improve. I also tested with a 30mm fan taped onto the E axis assembly, blowing right into the bond gear. Again, no noticeable improvement.

Bottom line, I conclude my stepper motor being too hot is not the source of my bad filament tips. But it was definitely something worth looking into.

I think my next step is to disassemble the z axis and try to replace the PTFE tubing, as mario-f4 reported. But that will have to wait until next weekend, at this point.

RE: MMU2S filament tips on unload

@oliver-r4

Hi Oliver.

This was the tip i was looking for.

Solved all my tip problems in a second.

The inner diameter of the PFTE tube was 2.15 mm and i also replaced it with a fresh tube.

Thnx

RE: MMU2S filament tips on unload

So after a couple more weeks of experimenting, I am no closer to getting reliable operation. And I've made it worse.

I replaced the hot end PTFE tube and now get strings. And perhaps because of that I am getting load fails at the hot end 1 out 10 times.

I replaced the PTFE tube between the MMU and the hot end with a 3mm ID tube, to allow extra-fat tips to retract without jamming (they still get jammed in the MMU internal PTFE tubes.

I tried the skinnydip postprocessing code, with insertion distance of 40 to 42 and it doesn't eliminate the strings.

I went back to the original factory settings, wondering if all the tinkering with parameters made it worse, but nothing changed.

I bought Prusament filament, nothing changed.

I am incredibly frustrated with the lack of any comprehensive guide on how to get this device to work reliably.

I'm giving up on using the MMU2 for all but the simplest prints.

RE: MMU2S filament tips on unload

@jeffrey-r10

Once your replaced the PTFE hot end tube you should have tips which have a diameter smaller than 2.0 mm so that they would fit into the heat break.

The problem with stringing has to be solved differently. I had that problem too when working with Verbatim BVOH. The PLA tips were fine, the BVOH tips had a lot of stringing. I got that problem solved by playing a bit with the Advanced filament settings. First I increased a bit the unloading speed at the start (for BVOH from 100 to 120). But that did not really help that much (for that particular filament). What solved the problem was changing the ramming settings. I just made the curve more steep towards the end. By doing that, the total rammed volume increased from 8 to 13 mm³. And that solved the problem. All of a sudden the BVOH tips look fine.

It seems that the tips are quite sensitive to the ramming settings. So maybe you try to test these settings a bit. That could solve the stringing mess.

RE: MMU2S filament tips on unload

@oliver-r4

Thanks for the suggestion. You motivated me to turn my printer on after a month off, and try one more time to fix the MMU2.

I loaded PrusaSlicer with all default settings to get rid of all previous decisions.

In alignment with your suggestion, I used mike-zoll's recommended settings of:

unloadspeed@start - 140 mm/s

unload speed - 90 mm/s

I looked at the ramming settings. The default is 2.5s, and a volume of 13. This did not have the "curve more steep towards the end" that you mentioned, so I chose a ramming setting of 3sec, and a corresponding volume of 18.

I set the PLA print temperature to 185; I don't feel comfortable going lower.

I am still getting long wispy threads. The tip ends look good. I just can't figure out a combination of settings that gets good tip shapes but no threads.

One side of me wants to keep on experimenting with different ram settings. But each experiment seems to take a half hour. I'm just exhausted from trying to get the MMU2 running reliably.

RE: MMU2S filament tips on unload

I see. One maybe stupid question: which filament you are using? And second question: Are you doing the test with a real tool change - means you print with one filament and check the tip of that after the printer has changed to another filament?

The reason why I'm asking - if you are printing with just one filament, the settings in the advanced section do not have any effect (except the unload speed). They show their influence just during a tool change.

RE: MMU2S filament tips on unload

Yes, the test is from real tool changes. I have a test print with five 2cm cubes, each with a different color.

I am using a variety of filaments, and yes, I realize that this could be the problem.

I'm using Hatchbox white, Hatchbox black, Amazon Orange, Overture red, and Prusament Brown.

The Hatchbox white and black seem the worst as far as threads go.

I recall that I saw threads on all of them, but when I just went to check, the Prusament and Amazon tips were clean.

I suppose I should buy a roll of Prusament black for a test print, but at $70 on Amazon, or $40 with shipping from Prusa and a 6-10 day wait, it would be an expensive test.

RE: MMU2S filament tips on unload

I don't know that Hatchbox stuff. Since I'm in Europe I have good access to Prusament which I use most. And that filament works like a charme for me. Did you try to increase the number of cooling moves? That may help as well.

RE: MMU2S filament tips on unload

I think I've tried 50 combinations of cooling moves and ramming speed. But frankly, there is so much contradictory advice on the forums that I I end up with useless combinations that I should never have tried. There is no comprehensive guide from Prusa to help. Seriously, if there was anything that said "if you have condition a, try b", then I might have a chance.

I'm going to give it one more try after I receive my replacement FINDA. And then give up.

RE: MMU2S filament tips on unload

unfortunately there is no guide - and I walked also the Long way of try and error of hope and frustration.

Most important are the mechanical mods (tubes and selector).

My process to adjust the Parameter is following:

- print a temp-calibration tower.

- select the optimal temperature for printing (regarding stringing, avoiding underextrusion). You do not need to select the lowest possible temperature. Check also for Surface Quality. If your Temperature is too low you might end up in Blocking of the Extruder sometimes during the print (very frustrating).

- with the selected temperature do a ramming Parameter test. Starting from nearly no ramming and going up. You will recognize a strong dependency on stringing. Check for stringing and tip length. Surprisingly if you increase ramming over the sweet spot the stringing is starting getting worse again. I do this test with short parts of Filament (30cm length) and fooling the FINDA manualy. Of Course you need a print Job with 5 "Colors" where every Color is just different with the ramming Parameter. If you do not get a tip with very low stringing try to increase cooling moves (I usually use only one move). Repeat this test at least one time to verify the values.

I experience also a dependency over the print time. I think if the printhead is heated up the stringing is getting just a bit worse.

Unload Speed usually 120;

RE: MMU2S filament tips on unload

@volker-h3

Thank you again for some good suggestions. This is the first time I've seen a recommendation to methodically step through the ramming settings, or that stringing could get worse with too high OR too low ramming settings.

But, this highlights the problem with the MMU2. Many people are sharing their stories of how they have debugged issues. But, all the stories are all different. You would think that Prusa would want to collect the most common/practical advice and post it. But they haven't. Sigh.

At this point, I suspect I am close. Replacing the PTFE tube seemed to be the big improvement.

What selector mod are you referring to?

I will try stepping through the ramming settings next week when I get a replacement FINDA (which died in the middle of the last MMU2 test print 🙁 ).

RE: MMU2S filament tips on unload

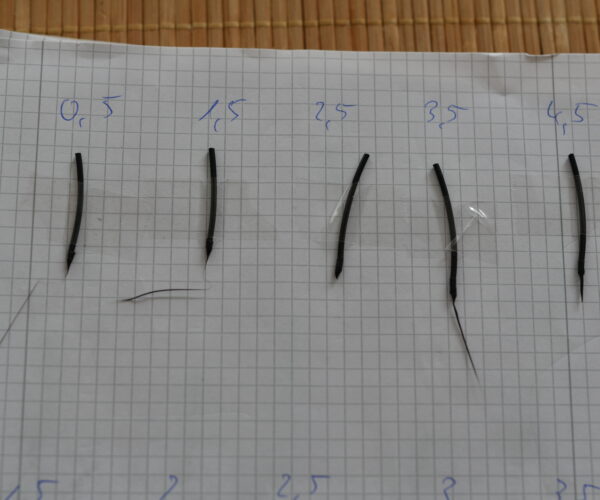

some Pictures of my tests. Black Filament; no specific stringing Problem:

you see the sweet spot at 2,5s.

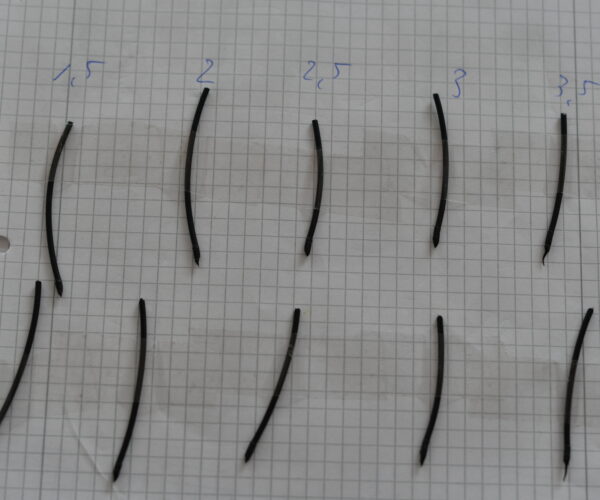

a repeat with smaller increments:

you can verify 2,5s with a slight tendency to 2s. I prefer shorter ramming. If you look closer you see that the tip length is also shorter which is good.

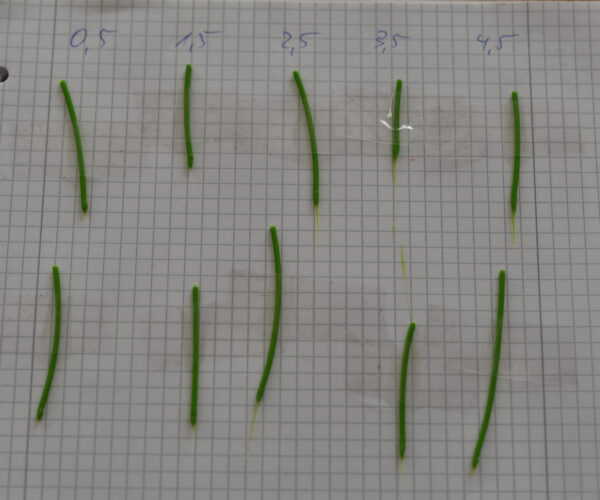

Next material green with a high tendency to stringing (in regular print):

you can see a very high tendency for stringing at longer ramming time (very suprising). Sweet spot seems arround 1.5s with still a very thin stringing - but wich is tolerable if you have tubes with larger ID (make sure that you replace not just the long tube from the selector to the Extruder but also all short tubes inside the MMU2.

Btw: my selector:

https://www.thingiverse.com/thing:3528314

RE: MMU2S filament tips on unload

@volker-h3

That was an excellent post. Thanks. You inspired me to do my own methodical test to find the best ramming setting for each of my filaments.

I spent 6 hours on Sunday walking through test prints with settings of 1 to 4.5 for each of 5 filaments. Starting with the default PLA filament settings, I did a test print of 5 cubes, and checked the tips of each color after a couple layers. I was happy when I got good tips on 3 of the colors, just by varying the ramming setting. Amazon white PLA: 3.0 Overture red PLA 2.5 Hatchbox orange 3.0.

For my black filament (both Hatchbox and Inland PLA+) I had to change other settings. Per other suggestions from this and other threads, I changed Unload speed at start to 110,unload speed to 90, load speed @ start to 19, and load speed =21. This gave me a pointy tip, but usable.

Unfortunately, the one I couldn't dial in was the Prusament brown PLA. Previously, this was the only one that worked. Now, i has a 20 cm thread at every setting. I did get a good tip at one test at ramming=3.0. But the threads returned on the next print.

So, last night, I go down to my basement shop to try some more testing. And now I am getting bad threads on all colors again. I changed nothing. Perhaps the basement was a little colder than Sunday, but that's the only change I can think of.

So, I am going to give up and remove the MMU2. I have 40 to 60 hours of tinkering and experimentation into trying to make this work and I've had enough. Maybe I'll do a test again in the summer, when the basement is warmer.

For those of you who have managed to to get the MMU2 working, I salute you.

For those of you who are thinking of buying one - don't.

RE: MMU2S filament tips on unload

Acutally i found out the tips don't matter that much. I run id 3mm ptfe between the extruder and the mmu2s. and id2.5 mm on the 5 short pipes in the mmu. and id 2.5 on the fillament feeding tubes. I also run the latest rc1 parts. And I run push through fitting mods on the selector and the extruder. With these changes i use the stock prasaslicer settings with 4 different brands of pla in it. And now i run 250+ tool changes without any problems.

RE: MMU2S filament tips on unload

@ruben-w

Sorry, its the threads that are screwing me up, not the filament tip shape. 20 to 30 mm threads on each tip will jam up the FINDA in just a few tool changes.

RE: MMU2S filament tips on unload

Hi that's your extruder motor that gets to hot. That's causing the stringing issue. I use this to fix that:

https://www.thingiverse.com/thing:2975582

The extruder get's so hot that the bondtech gears also get to hot. And that causes the filament issues.

RE: MMU2S filament tips on unload

An interesting idea. But I measured the extruder motor and bondtech gear temperature with an IR thermometer, and they were not that hot.

And, this is just another example of why Prusa should stop selling this. If the only way to get minimum functionality is to 1) replace all the PTFE tubes, 2) replace the selector per volker's mods, 3) replace the hot end to add another fan per your suggestion, and 4) do 1-2 hours of tuning tests everytime I use a new roll of filament, there is something wrong with this product.

RE: MMU2S filament tips on unload

Well that's the point with the mods i did i do not have to tune after a new roll of filament. I print 4 different kinds of pla even one is wood with the stock pla settings.