Load Filament - MMU not reversing enough

Prusa,

Every inch comes closer to a successful print, but it feels like the goal post is 100 miles away. My latest issue is that when loading, the filament isn't reversed enough - it at all on certain instances.

This happens at random. The unit loads a filament just fine, retracts it and moves to the next. Many times, however, the unit fails to reverse the filament enough. *pic attached in the next post (writing this on my PC, then will upload the pic via my phone).

Symptoms & Notes:

-The motors spin properly

-The filament is not getting stripped on the gears (more on this later).

-The filament holds both the selector wheel and carriage up and cause the next filament not to load.

-It can occur on different position #s (this particular one happened on position #2, where it's happened on all the other locations at one time or another).

-Multiple firmware images have been used. (I currently have v3.4.2 (V1.0.2) installed from October, but only for testing. All firmware exhibits the problem.)

-Everything moves freely - I have even slightly "lubed" up the innards of the PTFE tubes to ensure no friction is present. The filament slides perfectly without any issues. *That is, until the selector is engaged. The unit grips the filament exactly as expected and when it's active it's impossible to make the filament skip. It's very strong.

-I have adjusted the FINDA height up/down to each extreme and every 1/8th turn iteration in between.

-I have adjusted the spring tension on the MMU all the way from death-grip strength to barely holding on, and every 1/8th screw turn iteration in between.

As I mentioned, when this occurs - the motors are all spinning correctly, and the filament is moving (I can see it in the spool holders since I printed the auto-rewind ones from Thingiverse).

One painful aspect of this, is I can do a "load all" from the LCD, and it goes through the entire lineup. If I double-check to see and do the same "load all" procedure again, it can fail on one of the positions with this problem. I then verify the filament that failed to reverse completely, and its inspection absolutely proves that the filament was not stripped. *Pic also attached of a strand of this after the failure.

I'm seriously open to any ideas. Thanks for any help that can be provided.

Re: Load Filament - MMU not reversing enough

pics of the failure

Re: Load Filament - MMU not reversing enough

Every inch comes closer to a successful print, but it feels like the goal post is 100 miles away. My latest issue is that when loading, the filament isn't reversed enough - it at all on certain instances.

One possibility is that the filament tip is snagging on something inside the MMU. That would explain why it only happens sometimes--if the filament tip is just the wrong shape or position.

A good candidate for snags are the holes between the MMU drive gear and the selector head. Some people have drilled these out with a 2mm bit to make sure there's good clearance all the way through.

Re: Load Filament - MMU not reversing enough

Thanks for the suggestion. Just to make sure, what you're meaning is:

Drill out the PTFE tubes to 2mm immediately following the hobbed gears in the selector --> before the carriage.

Is it recommended to do this procedure on the selector carriage too, prior to the chamber with the little ball?

Re: Load Filament - MMU not reversing enough

My latest issue is that when loading, the filament isn't reversed enough - it at all on certain instances.

I can see two options:

1. The FINDA detects the filament end too early. Maybe the ball is not moving freely or something is dirty or the FINDA is too high, too low.

2. The filament got stuck and is physically not able to retract further. Here I would check the filament tip is not to thick, the tube is big enough and the pressure on the rolls are high enough (not slipping).

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Load Filament - MMU not reversing enough

This may be a silly question, but I didn't see it in the original post.

Did you configure/calibrate the feeding/retraction length for each filament position on the MMU?

I don't have my MMU2 yet, but apparently the hobbed gear diameters can vary by 10ths of a millimeter, which over the course of a layer, will lead to filaments that don't get completely retracted or completely fed into the extruder.

Re: Load Filament - MMU not reversing enough

@ nikolai

Thanks for the suggestions, the FINDA has been adjusted from all the way where it's pushing up against the filament noticeably, to where it's pulled so far out it barely registers - and every 1/8th turn in between. Basically, every conceivable height for the unit. It's possible that you may be onto something with the ball not having a smooth transition in movement - I may put some light sanding in the chamber walls to smooth everything out to test.

For the retaining screws holding the idlers in place, I've also adjusted those from their maximum tightness, back out to where they're barely in enough to hold the unit together, and of course every position in between as well.

@nullzero

Thanks for chiming in too. Yes, I've calibrated the tube lengths - but this particular problem isn't related to that. This is when the filament is loaded - only in the MMU, and not down to the extruder. Basically, this is the initial load, where it stages each of the filaments into the MMU and parks them all until its their time to get called into action.

Re: Load Filament - MMU not reversing enough

So... two things I'm going to try once I get home from prison /er... work.

1. Slightly drill-up the path from the MMU hobbed gears to selector carriage to 2mm or there abouts.

2. Lightly sand the chamber walls where the metal ball lives.

Hopefully this will draft some results. I'll keep this thread updated.

Re: Load Filament - MMU not reversing enough

Thanks guys, looks like it was a combo of a few things. I just ran the "load all" sequence over and over for about 30 minutes without the issue popping its head up.

If others experience this issue, here are the steps that appear to have resolved it.

1. Expand the small PTFE tubes that sit between the MMU hobbed bolts a tiny bit. Ensure there is ZERO friction when you push filament through. Mine was smooth before, but widening the inner diameter has helped.

2. Bore out the filament hole on the selector carriage a tiny bit for the same result of having ZERO friction. Don't go crazy, as I imagine flexible filaments aren't going to like the added room. *flex material is a challenge for another day for me.

3. Lightly sand out the inner chamber where the ball sits that triggers the FINDA. For an added measure, i sprinkled a little wd40 and polished the ball.

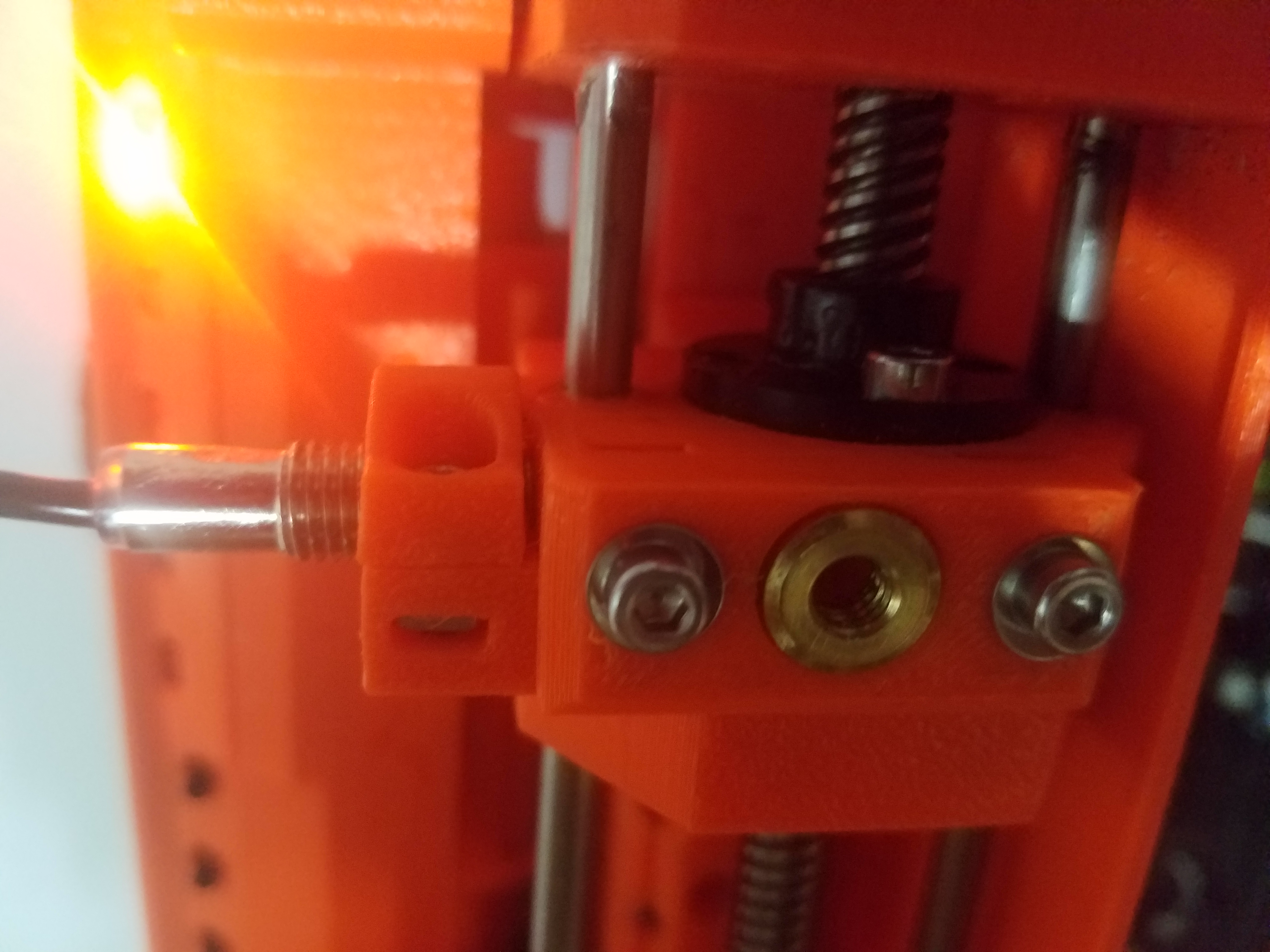

4. On opening the MMU, one thing I also noticed, was that the screws that hold the bowden coupler in place - one of them exits right into the path of where the ball sits in the chamber. It wasn't much, but I had tightened the screw enough that the tip was actually visible and protruding slightly on the inside of the chamber. It didn't look like it was enough to cause any issues, but it likely was. I added a washer to the screw to prevent it from happening. (pic attached)

Thanks for the assistance guys, it's much appreciated. i just hope now it's at least a few minutes before the next failure.

Re: Load Filament - MMU not reversing enough

I spoke too soon.

Still happening.

Re: Load Filament - MMU not reversing enough

*Update*

I have shortened the lengths of the PTFE between the filament spools and MMU, which should reduce the friction significantly as there's ultimately less contact area between everything. I've also tried the best I could to upsize the inner diameter with a 2mm wire braid strand *it's harder than it sounds).

Hopefully this nets positive results.

Re: Load Filament - MMU not reversing enough

Nope. The paperweight is getting heavier. Still the same issues.

Re: Load Filament - MMU not reversing enough

Are you printing PLA or PET? I had lots of PLA grinding issues with my MMU but now that I finally got it working it seems like featherlight tension on the MMU is the way to go. Otherwise the idler barrel can be dragged out of position by the filament and you lose traction.

Maybe it would be helpful to make a bunch of those stepper visualizers ( https://www.thingiverse.com/thing:2638857 ) so you can see when the motors stop and start moving.

For what it's worth the two things that fixed my MMU was switching to the http://github.com/TheZeroBeast/MM-control-01/ firmware and installing https://www.ebay.com/itm/131229025205 between the MMU and extruder and between the MMU and filament rolls. I left the short internal tubes alone. Did you make sure that you have the new narrower PTFE tube inside the E3D heatbreak? I misunderstood that assembly step and had to take apart my extruder twice. Hopefully Prusa gets the official firmware sorted out soon...

Re: Load Filament - MMU not reversing enough

Thanks for the suggestions. I do notice the more I bore out the PTFE tubes, the more success I seem to have. I like your idea of using 2.5 ID PTFE so i went ahead and placed an order for some. I'll likely use it to replace the small tubes between the hobbed bolts and selector carriage as well because I'd be willing to bet that's where my particular headache is stemming from.

Everything to this point has been problems just loading the filament, even after cutting it clean at an angle.