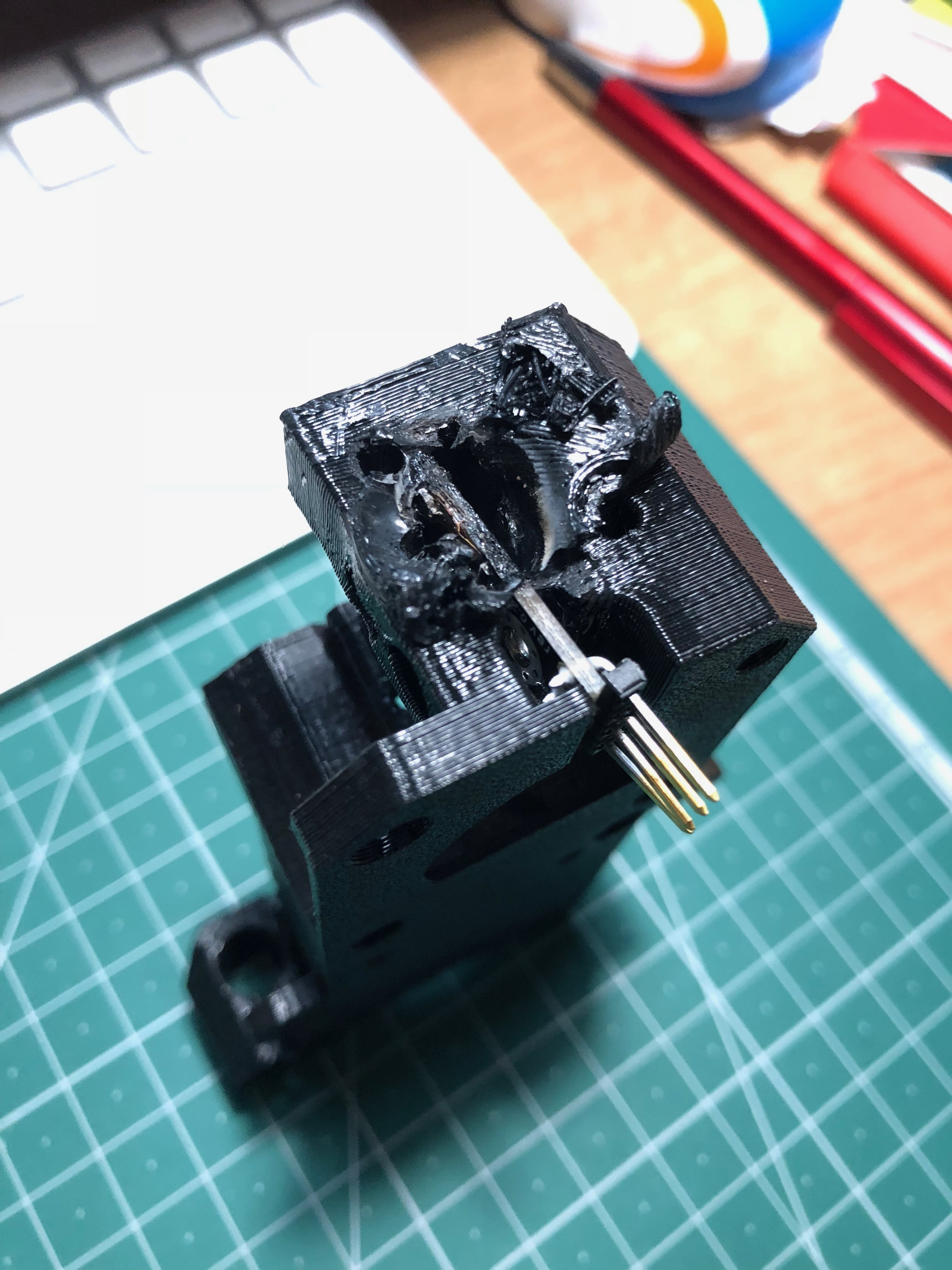

Filament sensor burned up!!!!!

My filament sensor burned up while the printer was working!!! Be careful!!!

Teflon is begin damaged, and all plastic parts near the sensor has been affeced and they must be replaced.

Waiting to get answer from support from Prusa, and replacement (I got my printer on February this year)

Re: Filament sensor burned up!!!!!

https://shop.prusa3d.com/forum/others-archive--f66/filament-sensor-just-burned-up--t14394.html

Thomas

Re: Filament sensor burned up!!!!!

https://shop.prusa3d.com/forum/others-archive--f66/filament-sensor-just-burned-up--t14394.html

Thomas

You are not alone. At least, both we got the same problem, with the same result... and it is not accidental... too much similarities in both cases not to think about. Honestly, I'm going to left the replacement sensor unconnected. Really I don't trust on it by now...

Re: Filament sensor burned up!!!!!

Hope they take of you.........

Jeez another thing to worry about

Prusa MK3 > MK4s

Prusa MK2.5 kit > MK3 > MK3s > MK4s

Prusa SL1 3D printer + Curing and Washing Machine (day1 order)

Taz6 - taken apart for space

CR10s4 - upgrading

Delta 3ku - dont use

Re: Filament sensor burned up!!!!!

Welp add me to the list of overheating sensor...thankfuly mine didnt catch fire.

My prints started failing like there was a clog but there wasnt...finally i could see the filament was thinning out right as went through the gears....then remembered the unlucky ones who caught fire.

So i literally unplugged my sensor and the next print is running fine.

*** Update, new sensor is being shipped out to me in 24-48hrs

Re: Filament sensor burned up!!!!!

Same.

I contacted Live chat and they sent me a new sensor very quickly.

I am too afraid to connect the new sensor too before I know what really happened to the old one.

I guess it might be caused by abnormal electric current. But I am not a specialist, just blind guess....

Re: Filament sensor burned up!!!!!

Yea I don't know anything about current either , but I'm hoping its a software thing some how even if we are getting free new parts, how can we ever trust an overnight print now, which a filament out sensor is perfect for.

I also wonder if its some how related to the MMU V2, I've had mine for a month now and this happens. The MK3 itself I've had for over a year.

Re: Filament sensor burned up!!!!!

it isn't related to the MMU at all. since almost the first day i got my MK3 there were reports of the sensor causing fires. there was a revision to the original pcb board but the problems kept happening. so from almost day one i disabled my filament sensor. i found out the MMU doesn't need it so i disabled it for the MMU2.0 as well. there is a problem with the boards design it is letting too much current on the board and it is causing a component to fail and then the entire thing dead shorts and you get melted parts or worse.

besides the Filament sensor the MK3 power supply has a high rate of failure.

part of the reason i converted the MK3 to a MMU2.0 was because i consider the printer to be substandard compared to the MK2/S, the mk2 is a workhorse. the MK3 is problems after problems so i treat it like an experimental model. i was extremely unhappy with the original Mk3 print quality even after replacing numerous parts and revisions the machine is still a complete disappointment. it still moiré patterns and had inconstant extrusion. it can't do TPU properly at all. but since i just use it as a back end printer for PLA and PETG i don't care as i have 3 other MK2/S units that run perfectly.

all that said in the last year the MK3 has improved greatly. a lot of the issues are in the Firmware and they still have not been properly fixed.

you still have to turn off layer shift detection as that will ruin a print also. basically you have to drop functionality of the MK3 to like a MK2 to make it work better.

it is extremely frustrating because i want the Mk3 to work better then the Mk2 and it does not.

“One does not simply use a picture as signature on Prusa forumsâ€

Re: Filament sensor burned up!!!!!

Thanks for the info Daniel, sounds like more hell than i was aware of since this is my first prusa... I wonder if they are actually doing anything about it and will issue a proper new board.

But at the same time as you said if the filament sensor is not even needed when you have the MMU V2 attached, when my new board gets here I am not even going to bother installing it. I thought they were both needed for proper filament out detection.

Re: Filament sensor burned up!!!!!

Thanks for the info Daniel, sounds like more hell than i was aware of since this is my first prusa... I wonder if they are actually doing anything about it and will issue a proper new board.

But at the same time as you said if the filament sensor is not even needed when you have the MMU V2 attached, when my new board gets here I am not even going to bother installing it. I thought they were both needed for proper filament out detection.

I've bitched and moaned quite a bit on the issues of the MK3. i cancelled 2 more orders for the MK3 printers after the first couple of months and switched in MK2/S printers because there is still big problems with the MK3. at the same time i want the MK3 to be a success because it has more potential then the MK2/S. I also opted not to convert to the 2.5 because it introduced some of the same problems that the MK3 has.

Side by side the MK2/S puts out better prints, it is just an unfortunate fact.

all that out of the way the MK3 is still a good machine and Great compared to many others on the market.

for whatever reason Prusa runs tight lipped on everything officially, they claim to never read these forums and never jump into the conversions to help.

these sensor board failures are kind of rare but with more and more people buying MK3s they are starting to become common. i think my MK3 was like number 260 or something(i would have to look in the box) so back then you would see somebody with a burnt up extruder but you wouldn't be sure what happened. people started to suspect the sensor board and it turned out there was an issue with the MASK on the PCB allowing solder to touch areas it shouldn't which shorted out the boards. they did revise it but the burn outs kept happening and many people at that point actually removed the boards physically from the machines. actually removing the boards allows you to install a better TPFE tube setup for a cleaner entrance to the extruder pully gears.(this is part of a problem when using TPU and the MK3)

so there was at least one official revision to the sensor PCB but otherwise you ask and get no answer from Prusa directly.

----

now i thought the MMU would need this sensor so when i built up my MMU2 i reenabled it for 2 prints. i then see posts like this once again with the sensor causing fires and so i asked about the need for the sensor and in fact the MMU for the most part is not using this sensor. so i turned it right back off and i ran a 5 color benchy and it completed no problem.

for me i have the sensor installed but disabled. but many people have gotten to the point that they take the sensor pcb out and disconnect the cable all the way back to the RIMBO. then they have experimented with new extruder body designs in the upper part to address filament hanging up and spewing out the sides of the pulleys.

“One does not simply use a picture as signature on Prusa forumsâ€

Re: Filament sensor burned up!!!!!

So, just a thought. There is very little warning about ESD (electro static discharge) in the documentation for the printers. ESD can and will cause problems such as the one being described here. I have not specifically looked at the sensor design, but I have been a hardware design engineer for 35+ years and have seen more examples of this than you can imagine.

It is possible that these sensors are being damaged from poop handling.

Re: Filament sensor burned up!!!!!

It is possible that these sensors are being damaged from poop handling.

As the people complaining think the sensors stink I suppose its possible. 😀

Neal

Re: Filament sensor burned up!!!!!

it could be static; it is possible to just run a static discharge wire from the pcb(maybe the 3mm screw mount) of the sensor from the extruder to ground. that would at least rule out static charge as a possible problem.

“One does not simply use a picture as signature on Prusa forumsâ€

Re: Filament sensor burned up!!!!!

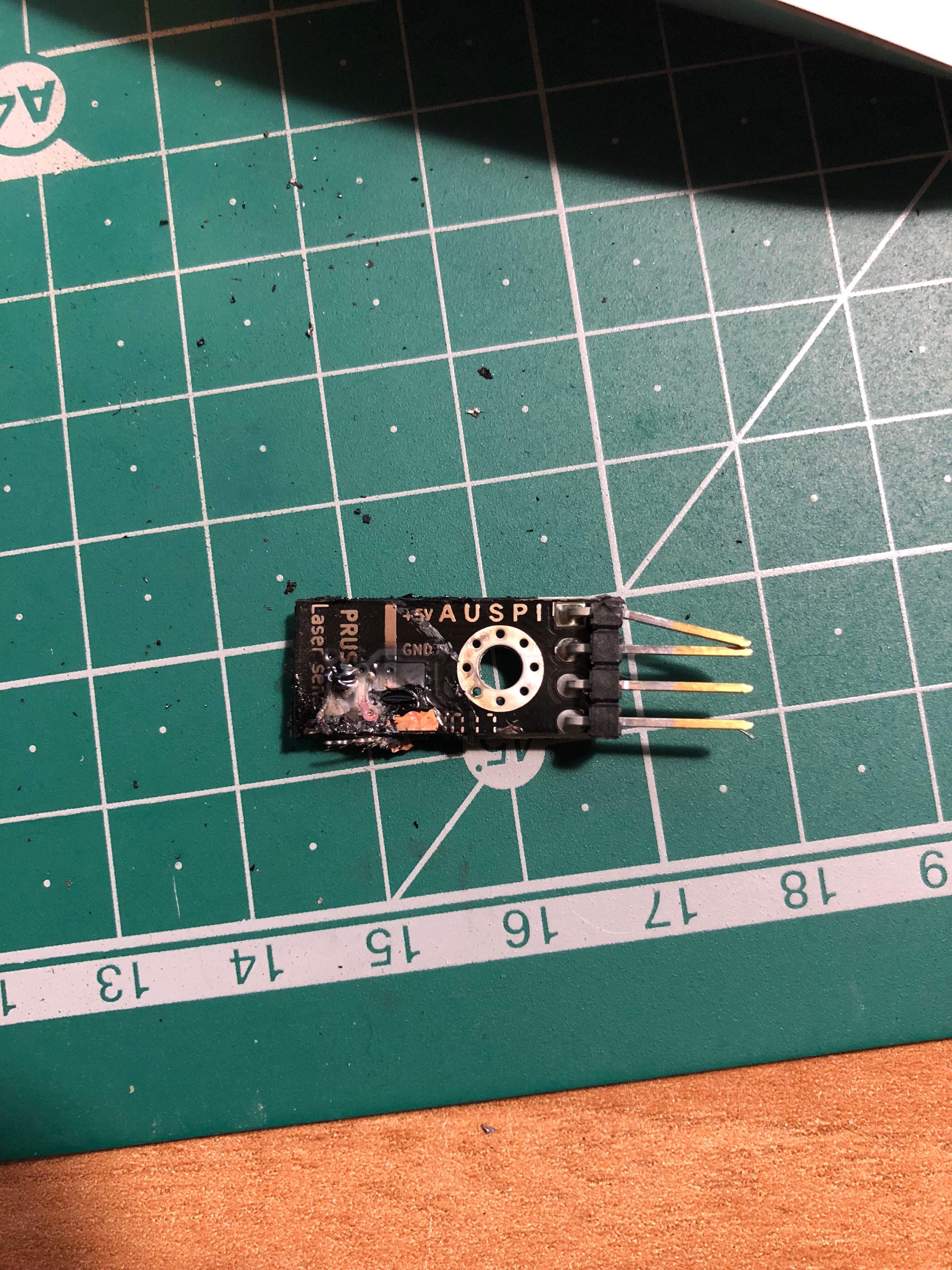

I've attached how the sensor is... I notice that the pub revision is different to the revision they send me in my last MK3 purhchased...

Basically, they have LEGAL RESPONSABILITIES. One thing is that you left alone, and you do a big mess after a failed print...that is bad use of the product... the other thing, and important, is that a design flaw produce a fire or problem in the printer, people, homes, ...

That is a serious thing, guys, to have a few answer and to tell that "it is a quite rare problem to investigate...".

They have do a fast replacement, but they didn't act really nice.

Re: Filament sensor burned up!!!!!

Yea my new sensor is on the way but I am not even going to install it.

They even tried telling me there are many things that could produce this much heat before the filament got to the gears..

Ummm MMUV2 no heat source...travel tube no heat source.... malfunctioning sensor boards strong enough to melt the extruder assembly...yea possible heat source lol

Also just chatted with a certain 3d print youtuber and they turned off their sensor since the first report of it going bad. Prusa really needs to publicly address this.

Re: Filament sensor burned up!!!!!

btw this issue goes back to it being the MK3. this was an issue when the mk3 first came out and again prusa will not publicly address it.

the first week i had my MK3, that sensor was turned off and layer shift recovery Disabled. even before the fires or melted parts from the board the sensor caused all kinds of false out of filament errors especially if you used PETG black or clear materials. pretty much every new feature the MK3 had over the MK2S caused a major problem or failure in a print and it just had to be turned off to make the printer reliable.

what i really hate is by now you would think they could of had this board analyzed to figure out exactly what the problem is. they tried to Revise the current getting to the extruder stepper and and sensor board back in one firmware revision but it just kept cascading. as a company that i thought valued the customers input as an open source machine they are just silent on almost everything we pointed out.

hands down the MK3 still makes lower quaility prints then the MK2S it was suppose to replace. there is material that the MK2S could handle no problem and the MK3 can't deal with at all, this is due to the change in the stepper motors and drivers. there is still under and over extrusion issues that are ignored. i complained forever the only positive i saw come out of it was suddenly they started to sell more printer parts through the store site.

Customer support was dropping the ball all the time. I had a machine down for 2 months dealing with customer support and i ended up buying a NIB MK2 because the wait time on a KIT printer was less then dealing with customer support, it dragged on for another month and in that time my spare parts printer kit came in so i could make the repairs i needed. part of the reason i stopped coming to the forums was because it was pointless, you had fan boys where they just loved prusa so much they refused to even listen to people that complained.

the way prusa is handing things since the MK3 release is making me less attracted to them all the time and if somebody else builds a better mouse trap then i want it at this point.

so i consider the prusa MK3 and variants an experimental Beta/alpha unit and i try to keep my eyes on the thing when i use it. meanwhile the Mk2s are Zhopping away weeks at a time with little input from me.

my opinion is too much current is getting to the board and slowly overloading the mosfet/transistor driver over time with constant heat and cool cycles the chance of failure increases and eventually the drive shorts internally and you get a dead short that heats up the PETG plastic and then the extruder body melts. i'm not even sure if there is a fuse on the rambo that pops when this happens. but if you kept your sensor off most of the time then your failure is less likely if you leave the sensor on all the time then after a couple of weeks it can blow.

“One does not simply use a picture as signature on Prusa forumsâ€

Re: Filament sensor burned up!!!!!

I had to do some serious looking to find where and how to plug the filament sensor in. Both ends are not polarized, and plugging in upside down and backwards at either end is way too easy. Especially having the cpu side connecting into a 10 pin socket - again without any polarization or keying. A disaster waiting to happen.

And I doubt the filament sensor board has any polarity protection.

Re: Filament sensor burned up!!!!!

no the cable is actually directional one side has a flat connector that goes in the rambo the other has a keyed connector with a lock. the lock is not used but it keys into the body of the extruder. you have to force it a little to go the wrong way and the manual covers the install with photos to keep things the correct way.

true the design could be tighter but it has been like this the entire MK3 generation. unplugging is easy as the wire is pushed in the rear cover of the X bearings holder. most people just remove the tension cover on the extruder body that gives access to the one 3mm bolt holding the pcb for the sensor board in then you can pop the top cover and remove the board. then just leave the sensor cable in the back of the extruder body and close everything back up.

“One does not simply use a picture as signature on Prusa forumsâ€

Re: Filament sensor burned up!!!!!

Filament sensor cable (use the lower row of pins in the connector and ensure the red wire is on the right, facing the outside of the board | Nr. 4). Double check the connector fits to all pins on the board!!! Misaligning the connector can damage the sensor!

Note connector above marked 4: And the cable is NOT polarized in any way shape or form.

Users can plug it in any which way ... and all except one is wrong and can fry the sensor.

Re: Filament sensor burned up!!!!!

That is why you read the manual, the same stuff happens with Raspberry pi setups with different connections to the GPIO interface.

i know right now things are tense but take a step back.

“One does not simply use a picture as signature on Prusa forumsâ€