Best boring/reliable/expensive filament for MMU2?

I've got a bunch of Matterhackers Build filament, but so far I haven't dialed in a setting that gets me reliable prints. I carefully watch the filament exchange, and at 195C, 4s RAM I see 95% perfectly formed tips and 5% some stringing. Since the exchange sequence is consistent, that means to me the filament is not consistent. Filament problem, not MMU2 problem. I'm still confident I can dial in a conservative setting that always works, but I'm not there yet.

So: I am going to buy a few fresh rolls of the "most reliable MMU2 filament" as recommended here. Current options:

1) four rolls of Prusament PLA (not shipped yet)

2) two unopened rolls Fillamentum PLA Extrafill Vertigo (Galaxy and Grey, inspired by the terminator head)

3) Order online? What is the best/most-reliable/price-is-no-object PLA to get? Preferably Amazon so I can try it this weekend...

My primary goal is material consistency. I can handle a bit of diameter variation (doesn't seem like it would massively impact the exchange), but consistent tips after unload is my goal.

Please share what has worked for you.

Thanks!

TIP 1: a flexible lamp with a bright LED spot (e.g. ikea jansjo Desk Work LED Lamp ), printer turned sideways, watching through the left side of the extruder, you can easily see how the string looks during the first part of the filament exchange.

TIP 2: if you are ordering an MMU2 or have one coming, order 2 rolls Prusa PLA or other other reliable PLA recommended here. Stabilize your prints with that before experimenting with affordable PLA (although Prusament is not expensive except for US shipping)

Re: Best boring/reliable/expensive filament for MMU2?

I've got a bunch of Matterhackers Build filament, but so far I haven't dialed in a setting that gets me reliable prints. I carefully watch the filament exchange, and at 195C, 4s RAM I see 95% perfectly formed tips and 5% some stringing. Since the exchange sequence is consistent, that means to me the filament is not consistent. Filament problem, not MMU2 problem. I'm still confident I can dial in a conservative setting that always works, but I'm not there yet.

Is it working in spite of the stringing? Or does it fail on those 5% where you see strings?

I wouldn't jump to the conclusion that the one-in-20 times you get strings is because the filament is inconsistent. There's so many variables that it's hard to be certain.

That said, I've had a lot of success with Inland PLA and ABS. Using generic PLA/ABS settings, I'm probably down to one failure per 500 or so material changes. I'm not checking for perfectly formed tips each time like you are, I'm just going by whether the filament loads and unloads properly.

Re: Best boring/reliable/expensive filament for MMU2?

Is it working in spite of the stringing? Or does it fail on those 5% where you see strings?

I wouldn't jump to the conclusion that the one-in-20 times you get strings is because the filament is inconsistent. There's so many variables that it's hard to be certain.

That said, I've had a lot of success with Inland PLA and ABS. Using generic PLA/ABS settings, I'm probably down to one failure per 500 or so material changes. I'm not checking for perfectly formed tips each time like you are, I'm just going by whether the filament loads and unloads properly.

It's not working reliably, and stringing seems to be the issue.

I've printed about 5 sheep (50% sized):

- pre-sliced GCode at 215: maybe 10 failures to load/unload, at least one layer lost

- slic3r at 205: better, but still at least 3 failures

- slic3r at 195 with more aggressive ramming/cooling: 1 load/unload fail, one lost layer soon after (typically in the face)

- slic3r at 190, same ram/cool: layer adhesion between layer 1/2, starting to get too cold for the filament

- slic3r at 190, same ram/cool, fan off first three layers: still adhesion problems

At 205/215 I was seeing significant stringing, but generally the print was able to survive.

At 195, 4s ram, 4 cool cycles, I saw my best result. Single unload fail in a 50% sheep. Still significant stringing, just mostly got lucky enough that it always made it back into the extruder. I'd say 1 in 10 bad strings ends up with some kind of load/unload/extruder jam.

I'm not done playing with the MH Build. I'm switching to a simpler set of 1cm cubes so that I remove one variable (layer variations) and also so that each layer has exchanges (the legs on the sheep generally work for me, and then I have to wait through an hour of white before I get the next exchange).

I also want to try replacing my nozzle (I'm using the one I've had on for a while). I want to see if a clean/new nozzle affects my tip forming.

Paul

Re: Best boring/reliable/expensive filament for MMU2?

I'm not done playing with the MH Build. I'm switching to a simpler set of 1cm cubes so that I remove one variable (layer variations) and also so that each layer has exchanges (the legs on the sheep generally work for me, and then I have to wait through an hour of white before I get the next exchange).

I also want to try replacing my nozzle (I'm using the one I've had on for a while). I want to see if a clean/new nozzle affects my tip forming.

Can I humbly suggest my purge calibration cube as a test print: https://www.thingiverse.com/thing:3102486 . Minimal variations between layers, and enough material changes to ensure you're getting a good read.

Re: Best boring/reliable/expensive filament for MMU2?

Can I humbly suggest my purge calibration cube as a test print: https://www.thingiverse.com/thing:3102486 . Minimal variations between layers, and enough material changes to ensure you're getting a good read.

Thanks. I downloaded that calibration cube stack. My issue for my current purpose is that it doesn't start doing two materials until about 5mm up. I just designed a quick sideways stack of 2-5 1cm cubes in fusion360 and I'm using that.

I may tweak it to have a single color base layer of 0.5mm just to get good adhesion, but I want to get to filament switches quite quickly. I'll post to thingiverse once I have it dialed in.

Re: Best boring/reliable/expensive filament for MMU2?

Here is what I plan to stress test with tonight (starting with just two colors):

Re: Best boring/reliable/expensive filament for MMU2?

Here is what I plan to stress test with tonight (starting with just two colors):

https://www.thingiverse.com/thing:3120233

This is a good idea... Thanks for sharing. This gets to swapping filament quickly, so one could evaluate tips much faster. While tweaking filament tips I like to even look at a tip while another filament is being printed.

Before testing, in the slicer I'll choose filament slots 1,3,5.

So say for instance mmu2 is printing with filament in slot 5, I can push out slot 1 filament or slot 3 filament and inspect the tip. If mmu2 is printing with filament in slot 1, I can push out slot 5 or slot 3 filament and inspect the tip.

The drive gear only moves one filament at a time. So the other filaments are free to be inspected or even recut if necessary.

Once done inspecting filament tip, be sure to pull it back into the correct position, so you wont have a misload. I do it at the spool holder, where the filament enters the bowden tube. I pull enough filament back into mmu2 so that tip of filament is flush with filament exit hole. (See note below)

This allows me to quickly judge the filament tip. If super stringy I can cancel print and try other ramming, temp settings right away before a jam occurs. If tip is ok, I'll let test print continue.

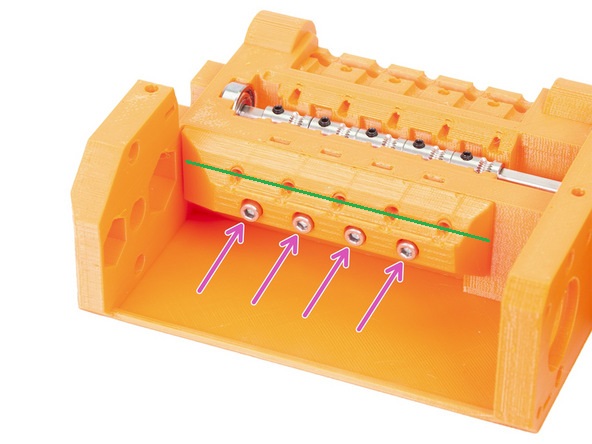

Note:

U can find the spot to leave the filament at b4 starting a print. Load filament into mmu2 correctly, such that you get a green light in that position on mmu2. Then move selector at least 2 positions away, so you'll be able to see the filament tip. Observe the position filament is left in after a successful filament load. MMU2 leaves the filament about a millimeter before the exit of the mmu2-front-PTFE-holder assemble. See photo below, leave tip behind green line.

Prusa MK3 > MK4s

Prusa MK2.5 kit > MK3 > MK3s > MK4s

Prusa SL1 3D printer + Curing and Washing Machine (day1 order)

Taz6 - taken apart for space

CR10s4 - upgrading

Delta 3ku - dont use