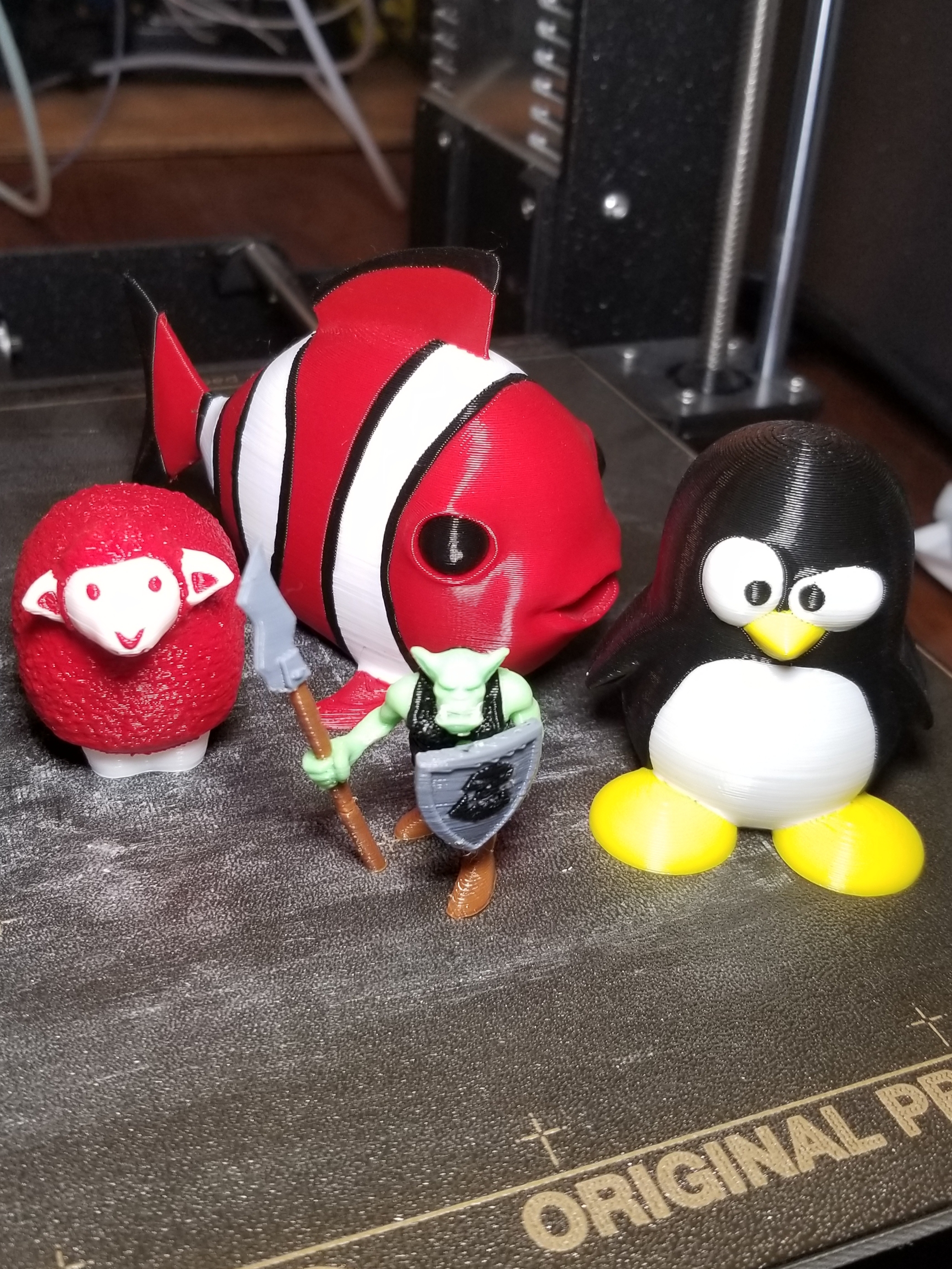

4 successes in a row

Starting to have more success than failures, knock on wood. It has definitely been a learning curve to get to this point. I want to consider this a mile stone for me. The more I'm able to print without issues the more my confidence in mmu2 builds.

Prusa MK3 > MK4s

Prusa MK2.5 kit > MK3 > MK3s > MK4s

Prusa SL1 3D printer + Curing and Washing Machine (day1 order)

Taz6 - taken apart for space

CR10s4 - upgrading

Delta 3ku - dont use

Re: 4 successes in a row

What have been your key adjustments?

For me I needed to lower my printing temp about 5C from single mode and tweak the ramming/unloading/cooling moves parameters to get a better shape on my tips. Printing with Atomic PLA.

I had 2 successes in a row so I'm taking a break from the MMU for a bit and printing the parts I need to setup a dry box.

Re: 4 successes in a row

Also, I just received my TXT plate. I notice yours looks all white/chalky? What caused that? Any tips for keeping the TXT plate looking new? My steel plate is beat to $*** so I'd like to keep the TXT looking nice.

Re: 4 successes in a row

Really great! I like it. Could you sum up your tweaks?

Re: 4 successes in a row

Also, I just received my TXT plate. I notice yours looks all white/chalky? What caused that? Any tips for keeping the TXT plate looking new? My steel plate is beat to $*** so I'd like to keep the TXT looking nice.

The tile in bathroom off main bedroom is being redone - creates lots of dust removing old tile...I forget to cover printer. So that's excess dust, combined with glue stick. Textured plate is great, just find it's less sticky then pei sheet. No glue stick needed for parts with a large bottom surface. Models with less bottom surface, I've needed glue stick. So u see dust and multiple glue stick applications.

@karl.z2

I will list the things the brought me success after work. But mostly following PJR, Peter.m27 and Jakub.d post. They have been extremely helpful with guides and advice. Then it was Chris warkcocki's troubleshooting videos and mmu2 pretty pla profile.

Prusa MK3 > MK4s

Prusa MK2.5 kit > MK3 > MK3s > MK4s

Prusa SL1 3D printer + Curing and Washing Machine (day1 order)

Taz6 - taken apart for space

CR10s4 - upgrading

Delta 3ku - dont use

Re: 4 successes in a row

glad to hear, while I wait for my MMU ive been uping my printer speed for something to do. so far no failures at 120 😀

a shame I will have to change my hotend. it's a finely tuned beast

I have a Prusa,therefore I research.

Re: 4 successes in a row

Set mine up yesterday and I got the sheep 90% printed before the failure. I'm using an upgraded festo adapter: https://www.thingiverse.com/thing:3094325 and installing upgraded spool holder parts: https://www.thingiverse.com/thing:3113520

I didn't install the new spool rollers and I fully believe my failure was because of how much force it takes the printer to pull the filament off of the stock rollers on the spool. The failed filament was completely ground from the printer struggling to pull the filament through the MMU. I could have saved it but I didn't have time to do it before work and I didn't want to leave the printer on all day.

A friend of mine is using those mods, linked above, and has had excellent success with the MMU 2.0 so far. He's even using PLA and BVOH at the same time.