Troubles with MMU2S: bad filaments ends, filament pills in hotend, failing color change.

Hello,

I'm quite unhappy with my MMU2s. At my first print, from 260 Color Changes (much encouraged for my first print, I know…) around 30 changes failed with manual action needed.

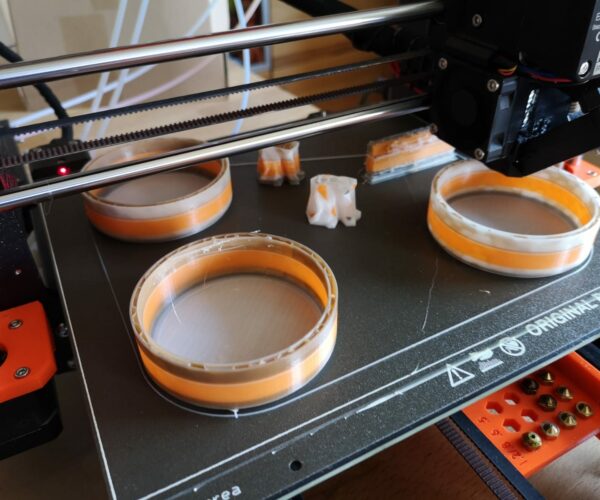

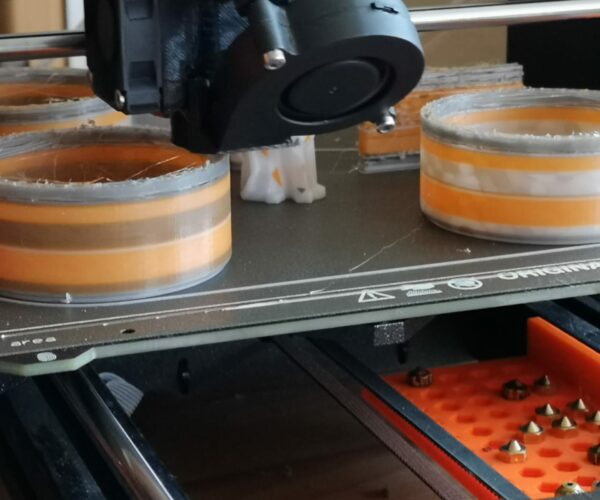

Many times, it just didn’t cut and lost some particles in the hotend shown in the picture

Also at some layers there where some serious under extrusion.

And the ends of my filaments are looking like this. Is it not forseen that the MMU cuts the ends?

Some tweaking with the temperature?

My Filament it new SUNLU PETG like this: https://www.amazon.de/SUNLU-Filament-Dimensional-Accuracy-Printing/dp/B07TYM5TLT

In grey, transparent white and orange.

I think my MMU needs some tweaking? So when It works like his, I can't use it....

Best Answer by pcweber:

Hi Manum,

Wow, where to start?

1. Idler alignment, this is extremely important, verify that when a channel is selected that the bearing on the idler lines up. This and grub gear alignment, important they are.

2. Filament drag, do all you can to reduce the drag on the filament, this is the culprit of under extrusion. Again, if the idler doesn't line up there will be more drag. Many recommend using PTFE tubing with a larger inside diameter. Try manually pushing the filament through to the extruder and pushing and pulling to verify the filament moves freely.

Verify the idler tension screws, I've taken the FINDA probe out and push the load button, the filament will flow until you push the button again. If the filament is held from the rear it should almost pull the printer over.

There my be other problems as well, ie. resets and misaligned idler after changing filament. These may be related to connection problems and or the two screw that hold the idler to the motor.

I hope this helps,

Phil

RE: Troubles with MMU2S: bad filaments ends, filament pills in hotend, failing color change.

Hi Manum,

Wow, where to start?

1. Idler alignment, this is extremely important, verify that when a channel is selected that the bearing on the idler lines up. This and grub gear alignment, important they are.

2. Filament drag, do all you can to reduce the drag on the filament, this is the culprit of under extrusion. Again, if the idler doesn't line up there will be more drag. Many recommend using PTFE tubing with a larger inside diameter. Try manually pushing the filament through to the extruder and pushing and pulling to verify the filament moves freely.

Verify the idler tension screws, I've taken the FINDA probe out and push the load button, the filament will flow until you push the button again. If the filament is held from the rear it should almost pull the printer over.

There my be other problems as well, ie. resets and misaligned idler after changing filament. These may be related to connection problems and or the two screw that hold the idler to the motor.

I hope this helps,

Phil

Stay safe and healthy, Phil

RE: Troubles with MMU2S: bad filaments ends, filament pills in hotend, failing color change.

@pcweber

Hi,

There where miltiple Problems. One was a wrong assembled hotend. I think the bearings and the idler is good aligned. But your awnser helped me, because I already fellt there was to muvh friction from the PTFE Tubes so I ordered a 4m tube with 3mm inner and 4mm outer diameter. Know I know, that's it.

I will mount it with threaded conections to the MMU (with printing a new teflon tube connector).

So It helped, thanks!