slicer print issue question

I'm getting small blobs/zits on the surface that i traced to "unretractions" on the slicer preview.

but i'm not sure what to do.

i tried changing "retract amount before wipe" which i changed from 0% to 10% that caused holes to appear through the surface.

i left everything with the prusa defaults but i'm not sure what i should play with.

“One does not simply use a picture as signature on Prusa forumsâ€

Re: slicer print issue question

does it change if you change the layer height? or anything? at least it shows you in slicer

I have a Prusa,therefore I research.

Re: slicer print issue question

i need the layer height to stay at .2mm

i outputted the test piece then compared the defects to the Slic3r preview. and it matches perfectly with the unretractions dot position on the preview.

the documentation is spotty i know its related to pressure of material inside the nozzle i think unretractions means when the nozzle comes back to the next layer after a Z-hop and the filament starts to get pushed into the nozzle to build pressure?

i don't know the best course of action to avoid hours of messing around.

i don't know if i should just mess with retract amount before wipe or increase the length of retraction put a negitive value for extra length on restart etc...

i looked at the pretty PLA settings and chris didn't mess with retraction much and i looked at the MMU pla settings.

seems they all went the route of using under-extrusion to compensate but i disagree with it. very pretty 3d printing is very weak on layering.

being an MMU things are more complex as well so was hoping somebody had a similar issue.

“One does not simply use a picture as signature on Prusa forumsâ€

Re: slicer print issue question

If you're using a MMU2, mine's still in the box, so I'm not sure how helpful this will be. You can set a negative under Printer Settings->Extruder 1->Retraction->Extra length on restart. This is the amount of filament pushed back into the nozzle after a retraction on move. On a non-MMU setup, you can set a small negative value here to reduce blobs. No idea if it works the same with MMU2.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: slicer print issue question

right, my question would be how is that different then just increasing the retraction length?

like if the normal length is .8mm

so when the nozzle i guess Zhops, it sucks the filament back in .8mm to drop the internal pressure slightly for the next layer.

verse saying "extra length on restart" with a negative number.

if extra length on restart is suppose to be rarely used then would it make more sense to say retraction length 1mm instead of .8mm rather then adding lets say -1mm to the extra length on restart.

i could see if one setting occurred before or after travel or the nozzle but ....

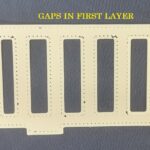

i have to setup a repeatable test but i know that when i set retract amount before wipe from 0 to 10% instead of blobs i got large holes in the surface. i don't know if the course of action would be start playing with just this one setting from 0-10% or this is the wrong path to go down. i was hoping correlating it directly to unretractions on the preview for the gcode would narrow it down

“One does not simply use a picture as signature on Prusa forumsâ€

Re: slicer print issue question

Normally, retraction before a move and de-retraction are the same length. If you specify 1mm for retraction, it will push 1mm back at the end of the move. Extra length on restart is for adjustments in addition to the retraction length. If you specify 1mm for retraction and 0.1mm for extra length, 1.1mm will be pushed at the end of the move. If you set a negative extra length of -0.1mm, 1mm will be retracted prior to move and 0.9mm at the end of the move, thereby (hopefully) reducing your blob problem.

right, my question would be how is that different then just increasing the retraction length?

I would suggest calibrating the extrusion rate for your filament before doing this however. You may just be suffering from a bit of over-extrusion overall.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: slicer print issue question

thank you 😀 i get it now.

i did some 20mm calibration cubes and i felt it was close enough to leave the extrusion multiplier at 1. i get that crappy MK3 wavy extrusion no matter what i do in the software with all the different calibrations i've done from steps to stepper motor linear calibration or how many parts i change.

“One does not simply use a picture as signature on Prusa forumsâ€

Re: slicer print issue question

If you're using a MMU2, mine's still in the box, so I'm not sure how helpful this will be. You can set a negative under Printer Settings->Extruder 1->Retraction->Extra length on restart. This is the amount of filament pushed back into the nozzle after a retraction on move. On a non-MMU setup, you can set a small negative value here to reduce blobs. No idea if it works the same with MMU2.

Cool, thanks for that tip. I didn't even think about trying that. When I use my ruby nozzle I noticed little blobs where ever I had a layer change. I just decided to live with it. But after seeing your tip I'll have to try setting a negative value next time I'm using the ruby nozzle. 😀

Re: slicer print issue question

so not finding a solution. i simulated a similar shape using a Vase cube 20x20x20mm and a 2% infill . if i left the thickness at 1mm per side then the defect was not present because the finished nozzle movement was located between both perimeter walls. however at one perimeter thickness this defect could not be hidden.

1) it is 100% the unretractions area causing the problem

2) if i changed the Extra length on restart to a negative number then instead of the blobs i get holes. in the surface.

i tried -.1mm and then -.05mm the holes were present but then i noticed longer areas of under extrusion with the smaller numbers.

3) if turned off "wipe while retracting" then i got holes similar to -.1mm extra length on restart.

with wipe turned off and the holes present i looked at the preview and zoomed in and turned the unretractions check off and then i could see the same break in the layer on the slice.

i continued to zoom in after gcode export and i can see the unretraction has a "internal infill" red line next to it and each retraction has a blue line overhang perimeter.

my perimeter speeds are 35-20mm/s while my infill speeds were 90ish. i tried dropping the infill speeds down to 80

running another test to see if that has any effect.

if you got any ideas let me know

“One does not simply use a picture as signature on Prusa forumsâ€

Re: slicer print issue question

[...] 2) if i changed the Extra length on restart to a negative number then instead of the blobs i get holes. in the surface.

I have seen -0.02mm recommended and have used that setting. I have not done any extensive testing to determine whether it's making a big difference, but it sounds like you're close. I'm still having a hard time visualizing why you're getting such specific patterns though.

i tried -.1mm and then -.05mm the holes were present but then i noticed longer areas of under extrusion with the smaller numbers.

[...] if you got any ideas let me know

Easiest would probably be to save your build plate and settings as a .3MF project file and upload it here so we can see exactly what you're seeing and try other settings.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: slicer print issue question

that last test i ran was not great, then I took some settings from my MK2S from about 2 years ago on a similar shape, and i used them on the MK3 MMU2 basically the speeds are cut way down.

between the settings for the mk3 and mk2 on the retraction menu there was no difference and nothing i was doing on the retraction adjustments was having an effect. so that led me to speeds...

using the mk2s settings I dropping the infill speeds from 90-80 down to 20.

The results were much better but the defects were still noticeable as i has set the seam position to random.

running the test again

in setting the seam position to aligned you didn't have the blobs since they were hidden in the corners.

so of course the print looked ok.

getting in the way additionally is my Prusa MK3 has the 602 issue

https://github.com/prusa3d/Prusa-Firmware/issues/602

this was one of the reasons i threw the POS in a box last year and ignored it. now i'm attempting to raise some quality out of the thing.

so far i've tried many of the suggestions on

https://github.com/PrusaOwners/prusaowners/wiki/How_to_make_prints_better_on_the_mk3

however none of the easy stuff had any effect at all. and i moved on to replacing parts.

i've taken my machine apart countless times in an effort to try to figure something out or hope to make a difference nothing works.

this 602 issue contributes to the issues on the print. prusa refuses to acknowledge the mk3 has major problems and i have been vocal about it in the past.

i've replaced the Z axis, Y-axis. been through so many revisions on the extruder.

replaced the feet with hard ones etc.

next i will be attempting

https://www.thingiverse.com/thing:2965241

to see what effect that has.

all this was part of the reason i went with the MMU2 as the entire mk3 machine is experimental and if i bricked it i wouldn't care and go back to my Mk2s machines.

i'll try and get more photos and information together over the weekend to post.

“One does not simply use a picture as signature on Prusa forumsâ€

Re: slicer print issue question

i read about the moon upgrade also and i bought the new moon steeper, i suspect nothing is going to fix it and make it work anywhere near the MK2s machines.

https://prusacommunity.com/to-the-moons-and-back/

“One does not simply use a picture as signature on Prusa forumsâ€

Re: slicer print issue question

urg, figures i thought i had the correct bearings for the idler change out but of course i do not. so that will have to wait.

i've run every calibration and have changed so many parts out on the machine between the XYZ and Extruder, this was why i got fed up with the MK3 in the first place. i have a Moon motor on order.

what is funny is with all the changes and the calibrations the surface 602 never changes so at this point i know it isn't me, because the surface always looks 100% the same, same from 9 months ago as today.

so i'm going with my newest settings which i'm not happy with but need to get it out on the MMU it is a 15 hour print.

some photos.

first a look at the 602 issue.

Moiré pattern no amount of linear tuning has any real effect.

the real issue, that lovely look of over and under extrusion pulsing from the extruder motor. again with all the parts changes and redesigns this never changes at all. which is really telling me more and more its that LDO extruder motor and that moon stepper might make the most difference. I've been reducing extruder pulley tension slowly and making prints and there is no change like prusa claims on the MK3 problems fixes page from mid 2018. also you can tighten the belts till the frame cracks or run them loose over 300 and the texture never changes. so it isn't the belts or bearing issues.

anyway moving on the the blobs zits weirdness, i think a lot of this is interrelated to 602 since better results occurred on the speed settings verse nothing happening on the retraction settings.

adjusting the extra on restart to -.05

playing with the speeds. this was where the better versions started to come out.

“One does not simply use a picture as signature on Prusa forumsâ€

Re: slicer print issue question

more testing more problems

it appears in this situation "only retract while crossing perimeters" had some positive effect.

i think part of it was the heat of the nozzle was shrinking back an area that was aligned with other unretractions and the result was a larger and larger hole as the layers rose upwards. with "only retract while crossing perimeters" retraction is "disabled when the travel path does not exceed the upper layer's perimeters" thus the extra blob is left and wiped kind of inward rather then outward. so it would fill in the hole a little more and when aligned there was more material present to fill in the former hole that would grow.

in "googling" i find 2 other people that showed the same issue however they never found a resolution.

one person tried adjusting the retraction speed from 50 mm/s down to 15 then up to 27mm/s to try and fix the stringing, they also had to play with the retraction length. but they still had stringing and the blobs or holes were still present but to a much smaller extent.

no follow ups occured after that post.

“One does not simply use a picture as signature on Prusa forumsâ€

Re: slicer print issue question

so big failure in the print that didn't work at all. back to the drawing board.

on the small sample print it looked better on the large run holes everywhere.

“One does not simply use a picture as signature on Prusa forumsâ€

Re: slicer print issue question

i tossed out all my printer settings and reset to factory

tossed out my print settings and reset to factory.

filament settings i kept as that was all my major changes to the machine.

running a new test to see the effect of resetting and starting over.

“One does not simply use a picture as signature on Prusa forumsâ€