Please help me with my MMU2

So, first post...

I've had my MMU2 for a few months now and have exactly 2 successful prints. I've done every single thing I can think of and I still can't get it to work. Can anybody please help me?

Here's what I've done:

replaced all ptfe tubes with 2.5/4 ptfe

flashed to latest firmware for both the mk3 and the mmu2

Modified the Festo on the hot-end to the pass-through variety. (from thread in this forum)

downgraded the firmware on the mmu2 because of a post I saw here.

modified all of the spool holders to this design ( https://www.thingiverse.com/thing:3113520 )

replaced the hot-end in it's entirety

Done the length calibration for all 5 spools about a billion times.

tried every slic3r setting I can think of

My tips look fine (maybe just a bit fat, but I can't seem to find a setting to thin them out)

I'm getting very little to no stringing.

My problem is that the filament seems to get jammed on load somewhere in the hot-end anytime after the first unload cycle of any color. I can hear it start to click and then eventually a flat spot gets ground in the filament.

I'm use 3d Solutech PLA and my settings are

Loading Speed at the start: 19

Loading Speed: 22

Unloading speed at the start: 140

Unloading speed: 90

Filament load time: 12

Filament unload time: 11

Delay after unloading: 0

Number of cooling moves: 3

Speed of the first cooling move: 20

Speed of the last cooling move: 20

Minimal purge on wipe towers: 15

Ramming Settings:

Total Ramming Time: 2.50

Ramming Line Width: 120

Ramming Line Spacing: 110

Extra Loading Distance: -6

I've tried to print the included mmu2 prints as they were, and then have tried multiple simple and hard models I've slice myself, all with 0 success.

Please is there anybody out there willing to help me out? I'm at my wits end.

-Lynn

P.S. Sorry if in wrong spot, first post and all...

Re: Please help me with my MMU2

so the filament is getting ground at the extruder gears? not the mmu gears?

I have a Prusa,therefore I research.

Re: Please help me with my MMU2

Please is there anybody out there willing to help me out? I'm at my wits end.

Hello Lynn and welcome to this forum. First of all please make a picture of the tip you're getting after first unload. It's easier for us to see where it might jam.

I would suggest following approach:

First you need to identify where exactly it's getting stuck. I'm always using the very powerful "Pause" function of the printer. So once the printer loaded the filament and you hear that jamming sound and you can see something is wrong, press select the Pause print function. Once the printer has parked the head. Select the nozzle temperature manually to the destination temp. Release the bondtech gear screws and open the window.

Now you should be able to see where the filament got stuck. You can also move it up and down, extrude some filament by pushing the filament with your hand down.

Again, it's very important that you can see and understand where exactly the filament gets stuck. It doesn't make sense to change elements of the printer without knowing the root cause.

Let us know the results and we can go from there.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Please help me with my MMU2

you can always preheat, then load to nozzle also. that might help for troubleshooting

I have a Prusa,therefore I research.

Re: Please help me with my MMU2

Prusa support via live chat is helpful too. They're slow but they'll provide you some good troubleshooting tips.

Re: Please help me with my MMU2

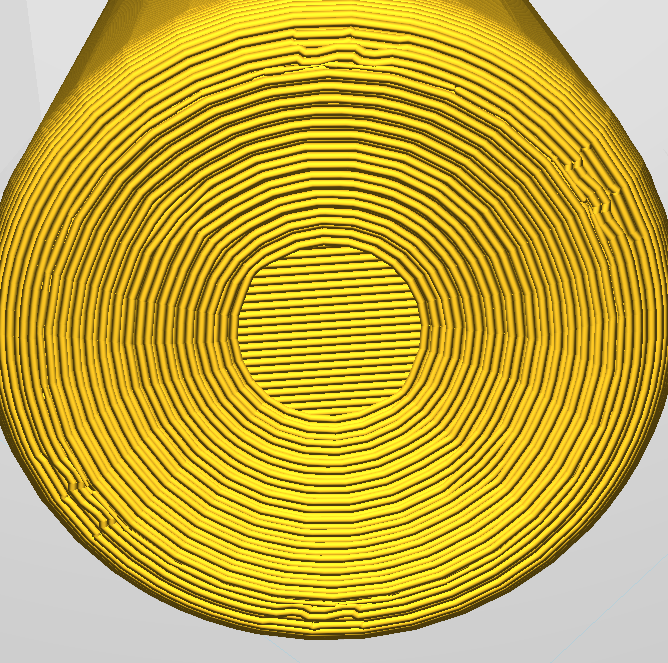

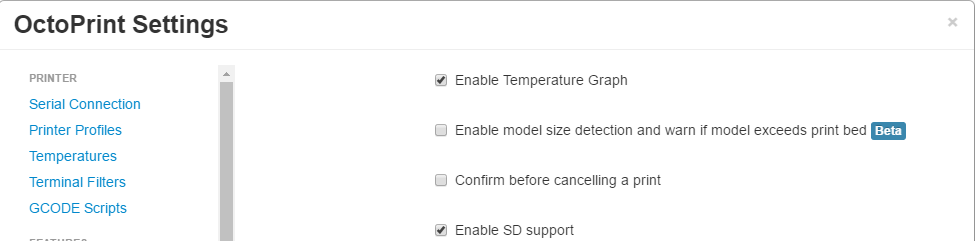

i am going to high jack this post as i think i am in the same boat. in my test print the green was not in use yet. i also attached my slic3r settings. i am wondering about going back a a 2.0mm hot end tube.

as a note if i try to just to PETG with no tool changes i get the same skipping behavior. if i bypass the MMU things seem fine.

Re: Please help me with my MMU2

i am going to high jack this post as i think i am in the same boat. in my test print the green was not in use yet. i also attached my slic3r settings. i am wondering about going back a a 2.0mm hot end tube.

Is it PLA or PETG?

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Please help me with my MMU2

the filament i am using is inland PLA. and the tips measure as follows.

green = 1.91mm

white = 2..04mm

light blue = 2.03

dark blue = 1.94mm (this one hasn't had many issue if any)

i guess what i don't get about the new PTFE tube i thought it was supposed to stop filament from getting bigger than the tube.

edit: which is why i mentioned the PETG it does seem to pick up flakes of PLA (i need to clean my gears) but on a single color print it will start off strong then seems to clog

Re: Please help me with my MMU2

the filament i am using is inland PLA. and the tips measure as follows.

green = 1.91mm

white = 2..04mm

light blue = 2.03

dark blue = 1.94mm (this one hasn't had many issue if any)

i guess what i don't get about the new PTFE tube i thought it was supposed to stop filament from getting bigger than the tube.

edit: which is why i mentioned the PETG it does seem to pick up flakes of PLA (i need to clean my gears) but on a single color print it will start off strong then seems to clog

The green one look pretty bad for PLA. Try with lower temp otherwise it will cause many issues.

My PETG looks like your green PLA.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Please help me with my MMU2

The green one look pretty bad for PLA. Try with lower temp otherwise it will cause many issues.

My PETG looks like your green PLA.

the green was not in use it was the white filament. and i have lowered the temp and that does help with stringing but the grinding that happens (as shown in my last photo) does not stop. a higher temp seems to lessen the grinding.

Re: Please help me with my MMU2

the green was not in use it was the white filament. and i have lowered the temp and that does help with stringing but the grinding that happens (as shown in my last photo) does not stop. a higher temp seems to lessen the grinding.

Ah, ok. Grinding can be eleminated (highly reduced) by recalibrating the tube length and set the "Loading speed at the start" higher to something around 20 mm/s.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Please help me with my MMU2

the green was not in use it was the white filament. and i have lowered the temp and that does help with stringing but the grinding that happens (as shown in my last photo) does not stop. a higher temp seems to lessen the grinding.

Ah, ok. Grinding can be eleminated (highly reduced) by recalibrating the tube length and set the "Loading speed at the start" higher to something around 20 mm/s.

even if the extruder is the part doing the grinding / skipping? from what i can tell the MMU is no longer the source of the grinding.

2.5mm ID / 4mm OD tubing (tubes feeding the mmu, selector, bowden) <-this made a huge improvement

a ton of slic3r settings and length calibration.

i feel like the hotend PTFE tube might be my problem but i thought that the new PTFE tube was supposed to prevent tips from getting too big.

Re: Please help me with my MMU2

the green was not in use it was the white filament. and i have lowered the temp and that does help with stringing but the grinding that happens (as shown in my last photo) does not stop. a higher temp seems to lessen the grinding.

Ah, ok. Grinding can be eleminated (highly reduced) by recalibrating the tube length and set the "Loading speed at the start" higher to something around 20 mm/s.

even if the extruder is the part doing the grinding / skipping? from what i can tell the MMU is no longer the source of the grinding.

2.5mm ID / 4mm OD tubing (tubes feeding the mmu, selector, bowden) <-this made a huge improvement

a ton of slic3r settings and length calibration.

i feel like the hotend PTFE tube might be my problem but i thought that the new PTFE tube was supposed to prevent tips from getting too big.

getting stuck in the PTFE tube in the hotend is a symptom and not the real problem. Setting the "Loading speed at the start" as nikolai.r pointed out will help with this problem. When set correctly it will get the filament out of the hot zone fast enough to shape it to a smaller tip. Give it a try first as see what it effects.

Mistakes happen. It's what you do next that counts . Current Printers

Original Prusa i3 MK2.5 +MMU2

Ultimaker Original +

Ender 2

Re: Please help me with my MMU2

getting stuck in the PTFE tube in the hotend is a symptom and not the real problem. Setting the "Loading speed at the start" as nikolai.r pointed out will help with this problem. When set correctly it will get the filament out of the hot zone fast enough to shape it to a smaller tip. Give it a try first as see what it effects.

so "Loading speed at the start" only influences the initial pull of the filament during ramming? i was under the impression that it had more to due with the loading speed from the MMU to the extruder.

my "Loading speed at the start" is set to 19 which seems to be the value most pushed around here for this setting.

Re: Please help me with my MMU2

getting stuck in the PTFE tube in the hotend is a symptom and not the real problem. Setting the "Loading speed at the start" as nikolai.r pointed out will help with this problem. When set correctly it will get the filament out of the hot zone fast enough to shape it to a smaller tip. Give it a try first as see what it effects.

so "Loading speed at the start" only influences the initial pull of the filament during ramming? i was under the impression that it had more to due with the loading speed from the MMU to the extruder.

my "Loading speed at the start" is set to 19 which seems to be the value most pushed around here for this setting.

My mistake I had the setting mixed up entirely. Per Slic3r PE Loading speed at start = Speed used at the very beginning of loading phase. I was thinking of "Unloading speed at start" That effects how fast the filament is pulled out after ramming. I have seen anywhere from 100mm/s to 140mm/s depending on the filament brand people are tuning.

Mistakes happen. It's what you do next that counts . Current Printers

Original Prusa i3 MK2.5 +MMU2

Ultimaker Original +

Ender 2

Re: Please help me with my MMU2

getting stuck in the PTFE tube in the hotend is a symptom and not the real problem. Setting the "Loading speed at the start" as nikolai.r pointed out will help with this problem. When set correctly it will get the filament out of the hot zone fast enough to shape it to a smaller tip. Give it a try first as see what it effects.

so "Loading speed at the start" only influences the initial pull of the filament during ramming? i was under the impression that it had more to due with the loading speed from the MMU to the extruder.

my "Loading speed at the start" is set to 19 which seems to be the value most pushed around here for this setting.

My mistake I had the setting mixed up entirely. Per Slic3r PE Loading speed at start = Speed used at the very beginning of loading phase. I was thinking of "Unloading speed at start" That effects how fast the filament is pulled out after ramming. I have seen anywhere from 100mm/s to 140mm/s depending on the filament brand people are tuning.

no worries happens to the best of us. i am going to try 140mm/s after my current print finishes up.

Re: Please help me with my MMU2

no worries happens to the best of us. i am going to try 140mm/s after my current print finishes up.

140mm/s = placebo effect. Sorry, but the firmware limits the max E feedrate to 120 mm/s and that speed is not achievable on all printers at 1/32 stepping.

Yes, the initial unload has to be fast, but maybe people are trying "too fast". I tested slower, starting at 80 and ended up at 93, which seems to be a value that my hardware can handle.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Please help me with my MMU2

i am wondering about going back a a 2.0mm hot end tube.

Are you saying you changed out the PTFE tube in the hotend to a 2.5mm ID tube? If so, that is a huge problem.

Re: Please help me with my MMU2

i am wondering about going back a a 2.0mm hot end tube.

Are you saying you changed out the PTFE tube in the hotend to a 2.5mm ID tube? If so, that is a huge problem.

In short no.

<rant>

what I am saying is that most if not all of the PTFE tubes Prusa chose to ship with the MMU2 are a problem. There is no real need for the tubes (feeding the MMU, in the MMU and the Bowden) to be 2.00mm ID as you can’t completely get rid of slop on the filiment. the “new” hotend tube that is supposed to be 1.85mm and doesn’t really seem to work if the printer is pulling out ends that are 2.0mm or bigger tips. My printer seems to be able to retract ok but at some point when it reenters the hotend it will stop extruding and then grind the filament(at the extruder, like what the OP was reporting). I am thinking that the hotend tube should be 2.0mm not 1.85mm

</rant>

and i should have an update tonight on if the "Unloading speed at start" increase helps my current profile is set to 80 i was thinking about going back to 110