No longer capable of retraction

Had just finished my MMU2 upgrade and began printing a dual material benchy. Managed to get through about 30% before hitting my first error, fast blinking light. Fixed that by removing strings from the FINDA sensor, things seemed fine. Got to about 40%, had a slow blinking light this time. While trying to fix it, had a lot of trouble getting the pulley to grab the filament. Noticed some yellowish flakes/powder near the 2nd pulley, so I removed the filament to inspect better. Looks like the pulley has been extremely worn down. The 1st one also seems to have a bit of wear, but not nearly as bad as the 2nd one.

If I let the pulley motor run, I see that the powder is pretty evenly distributed on the 2nd pulley but less so on the 1st one.

Pretty frustrated at this point, not sure what to do. 😳

Re: No longer capable of retraction

I'm just starting as well, but I spent a bunch of hours yesterday watching, so hopefully some of my thoughts are useful.

If you have grinding powder in the MMU pulley, it is trying to move filament that doesn't want to move.

Sources of resistance:

The last two seem the most likely culprits.

Bowden length calibration: do it repeatedly and in different scenarios. Do it with freshly cut, newly loaded filament. Then try it in mid print (real print, with ram/retraction) so you can see what it looks like with a real melted end.

Filament head catching: For me, this is typically strings. With my Matterhackers Build (aka cheap) PLA, 85% of the retractions with stock Slic3r PLA settings (except for 200C) seem to be beautifully formed heads with no string. 10% have strings, but not that long, don't seem to do anything. One in 20 has a string that goes on and on for inches! Those strings can cause all sorts of issues:

- Failed unload detected when the string stays in the finda after retract

- Failed load detected when the string catches in the MMU2 and prevent load

- Failed print when they make it past the selector, but don't enter the extruder cleanly (just below the bondtech)

The fix: I see no other option but to find settings where you have zero strings. For me that will mean a bunch of playing with ramming/retract settings using my filament (similar the the inland PLA thread). The other option is to switch to filament known to string less, but as I've got $200 invested in a rainbow of matterhackers, I'm motivated to make it work.

Re: No longer capable of retraction

Don't think the pulley is worn, just full up with filament. You should be able to clean out the pulley with a sharp knife and then you need to increase the tension of the MMU to prevent this happening.

The problem is mis-match feed speeds during the phase where both MMU and Bondtechs are feeding.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: No longer capable of retraction

I'm just starting as well, but I spent a bunch of hours yesterday watching, so hopefully some of my thoughts are useful.

If you have grinding powder in the MMU pulley, it is trying to move filament that doesn't want to move.

Sources of resistance:

The last two seem the most likely culprits.

Bowden length calibration: do it repeatedly and in different scenarios. Do it with freshly cut, newly loaded filament. Then try it in mid print (real print, with ram/retraction) so you can see what it looks like with a real melted end.

Filament head catching: For me, this is typically strings. With my Matterhackers Build (aka cheap) PLA, 85% of the retractions with stock Slic3r PLA settings (except for 200C) seem to be beautifully formed heads with no string. 10% have strings, but not that long, don't seem to do anything. One in 20 has a string that goes on and on for inches! Those strings can cause all sorts of issues:

- Failed unload detected when the string stays in the finda after retract

- Failed load detected when the string catches in the MMU2 and prevent load

- Failed print when they make it past the selector, but don't enter the extruder cleanly (just below the bondtech)

The fix: I see no other option but to find settings where you have zero strings. For me that will mean a bunch of playing with ramming/retract settings using my filament (similar the the inland PLA thread). The other option is to switch to filament known to string less, but as I've got $200 invested in a rainbow of matterhackers, I'm motivated to make it work.

Hi Paul, thanks for the response. While you bring up valid points (and I checked for all of them), my problem seems to persist. I checked for strings (cleaned out the FINDA, checked for resistance at various points of the assembly, opened up the pulley body, etc.), made sure the filament wouldn't catch on anything by realigning the FESTO/pneumatic coupler interface near the MMU, unscrewed the 4-screw part that fastens the 5 PTFE tubes leading back to the filament rolls, checked to make sure it wasn't the spool holder causing issues. I recalibrated the Bowden length prior to my print because it refused to work otherwise, so that's not the problem.

I did notice some success varying the tension on the set of bolt/springs that determine contact between the bearings in the tumbler and the pulleys; unfortunately, it was sporadic success. Sometimes the filament would move a bit, stop, and then move again some more, but never continuously (as the pulley motor suggests they should). To verify whether this was the case during the actual print, I removed the FESTO/PTFE tube (orange) between the MMU2 assembly and the extruder immediately after getting a flashing red-green light (signaling that I had fixed the problem). Instead of running the filament all the way down to extruder, the filament only ran part way.

In conclusion, I believe that the pulleys and/or bearings are failing to make full contact continuously.

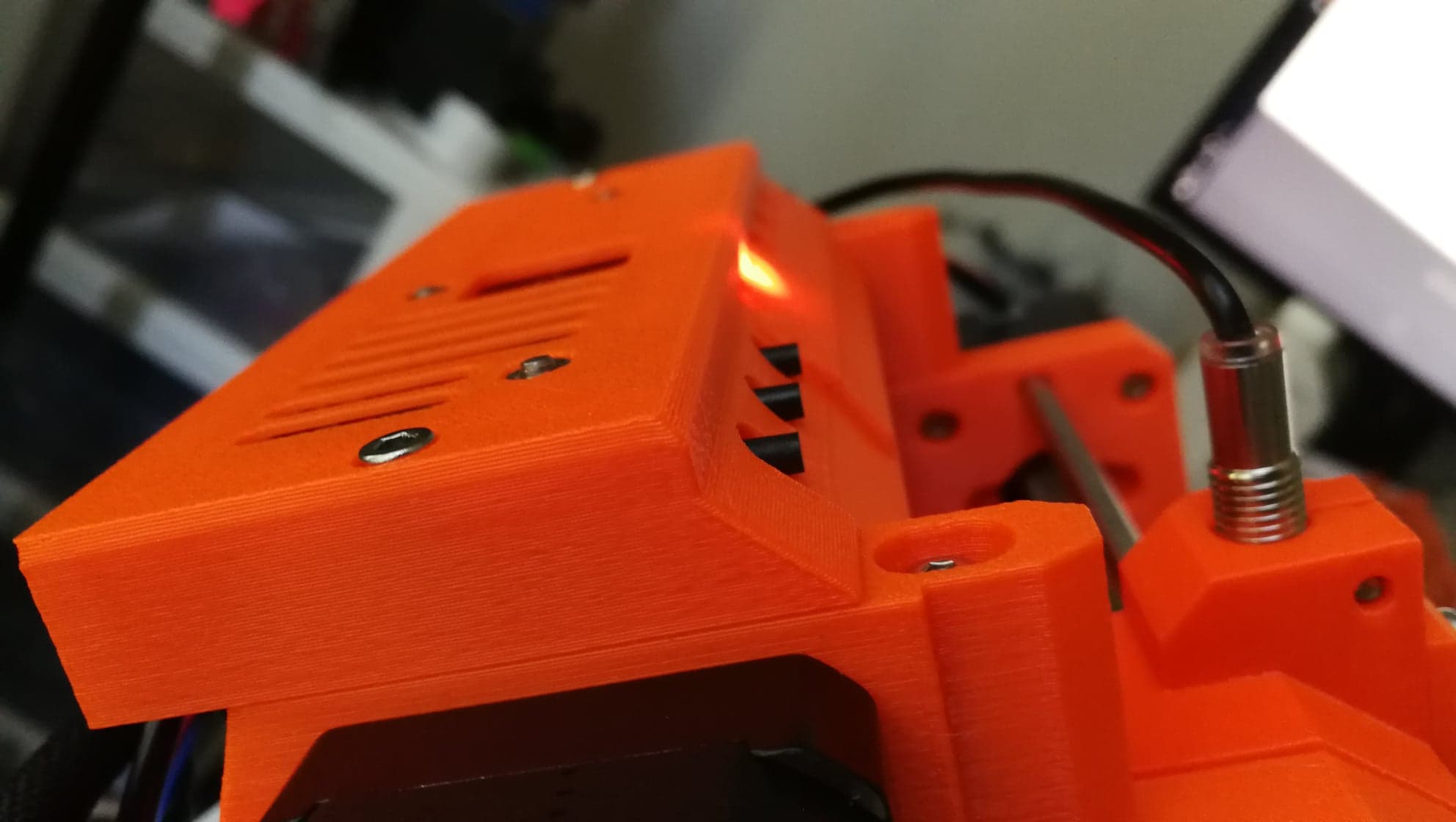

EDIT: As I was typing this, I decided to play around with the tension a little more. Turns out I needed to add way more tension than I anticipated; it seems to be somewhat reliable now. My spring/screws are now about 2.3-2.4mm under the surface:

Thanks again for making me check the rest though, I'm sure it'll prevent more problems in the future!

Re: No longer capable of retraction

Don't think the pulley is worn, just full up with filament. You should be able to clean out the pulley with a sharp knife and then you need to increase the tension of the MMU to prevent this happening.

The problem is mis-match feed speeds during the phase where both MMU and Bondtechs are feeding.

Peter

That sounds about right, what material are the pulleys made out of? Also, immediately ran into another problem right after:

The filament I was working with may have gotten stuck in the selector after I pressed the right button to continue the print...

It seems to be jammed pretty hard, but I don't really have the ability to tell the selector to move back to filament 1 so I can clear it.

I cut filament 1 because I thought it'd be easier to remove if I did that. Not sure if that's helping.

Any suggestions? 🙁

EDIT: To clarify, the selector seems to be stuck between filament 1 and filament 2.

Re: No longer capable of retraction

You have filament jammed between selector and idler.

Please be very careful with this situation; if you use force, you could cause the blade to swivel and put a huge hole in you thumb (and yes, I know this from personal experience).

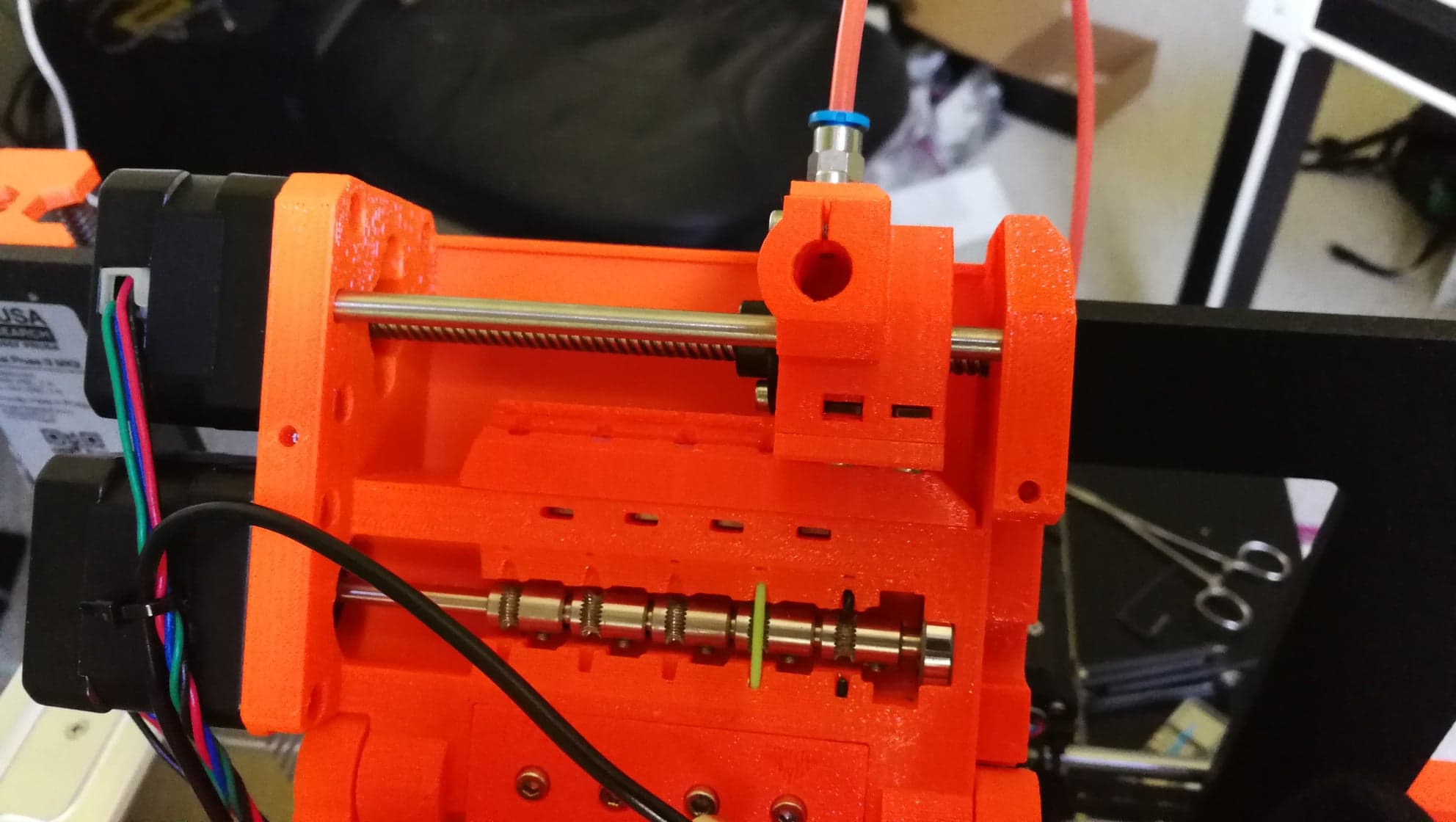

You need to unscrew the motor, then turn the lead screw to move the motor out, push out the two metal rods and remove the selector.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: No longer capable of retraction

You have filament jammed between selector and idler.

Please be very careful with this situation; if you use force, you could cause the blade to swivel and put a huge hole in you thumb (and yes, I know this from personal experience).

You need to unscrew the motor, then turn the lead screw to move the motor out, push out the two metal rods and remove the selector.

Peter

Oof, good to know and sorry to hear that.

So I've managed to clear the jam with your advice, but because the selector isn't lined up with either filament 1 or 2, I can't seem to proceed. I think I'll try and manually realign them (guess I'll unplug the selector motor and move the selector into place?).

Re: No longer capable of retraction

So I've managed to clear the jam with your advice, but because the selector isn't lined up with either filament 1 or 2, I can't seem to proceed. I think I'll try and manually realign them (guess I'll unplug the selector motor and move the selector into place?).

Just press the MMU reset button. If you had a print running, forget it 🙁 sorry...

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: No longer capable of retraction

So I've managed to clear the jam with your advice, but because the selector isn't lined up with either filament 1 or 2, I can't seem to proceed. I think I'll try and manually realign them (guess I'll unplug the selector motor and move the selector into place?).

Just press the MMU reset button. If you had a print running, forget it 🙁 sorry...

Peter

So I decided to try unplugging the selector motor first to see if it was possible...and you're right, wasn't very useful. In fact, the printer reset so I got the same result anyways. Thanks for the help, hopefully I won't end up in this situation next time. 😆

Re: No longer capable of retraction

So I tried the same print again, managed to get further than last time before my first error. Long story short, stuck at the rapid flashing led again 🙁

The filament was worn down, so I made a cut prior to that and pressed the middle button to let it do its thing. Despite tensioning properly, I still couldn't get the bearing/pulley to grab on. This is when I noticed that the springs weren't even being exerted; the tumbler wasn't rotating far enough for the bearing to make contact with the filament.

I heard grinding earlier; I assumed it was the pulleys eating at the filament, but maybe it was the tumbler struggling to rotate? Could it be confused about its position? How does the tumbler act normally?

Re: No longer capable of retraction

Could it be confused about its position?

Yes it could. But it's not likely.

On a reset the idler moves to a stop so it "knows" its position; thereafter it assumes it is in the correct position. I have never had a problem with this, so I would suggest that you remove it and check it out - other have reported delamination/cracking of the idler, particularly where the two screws fix it to motor shaft.

If it's OK, replace it and ensure that it turns freely and can properly hit the stop - and then can freely move away from the stop.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: No longer capable of retraction

The filament I was working with may have gotten stuck in the selector after I pressed the right button to continue the print...

It seems to be jammed pretty hard, but I don't really have the ability to tell the selector to move back to filament 1 so I can clear it.

I cut filament 1 because I thought it'd be easier to remove if I did that. Not sure if that's helping.

Any suggestions? 🙁

EDIT: To clarify, the selector seems to be stuck between filament 1 and filament 2.

When I had this I had luck directly rotating the lead-screw with my fingers (power off, no motor disassembly) to get the selector shifted back over.

Re: No longer capable of retraction

Could it be confused about its position?

I would suggest that you remove it and check it out - other have reported delamination/cracking of the idler, particularly where the two screws fix it to motor shaft.

Thanks, I'll make sure to check when I get off work.

Re: No longer capable of retraction

The filament I was working with may have gotten stuck in the selector after I pressed the right button to continue the print...

It seems to be jammed pretty hard, but I don't really have the ability to tell the selector to move back to filament 1 so I can clear it.

I cut filament 1 because I thought it'd be easier to remove if I did that. Not sure if that's helping.

Any suggestions? 🙁

EDIT: To clarify, the selector seems to be stuck between filament 1 and filament 2.

When I had this I had luck directly rotating the lead-screw with my fingers (power off, no motor disassembly) to get the selector shifted back over.

Neat, didn't think that'd be possible. Sounds like the selector motor isn't engaged in that state then. With my current track record, this info will probably come in handy. 😆

Re: No longer capable of retraction

Could it be confused about its position?

I would suggest that you remove it and check it out - other have reported delamination/cracking of the idler, particularly where the two screws fix it to motor shaft.

Thanks, I'll make sure to check when I get off work.

So the idler is fine, but you won't believe how I fixed the problem.

The filament I was working with may have gotten stuck in the selector after I pressed the right button to continue the print...

It seems to be jammed pretty hard, but I don't really have the ability to tell the selector to move back to filament 1 so I can clear it.

I cut filament 1 because I thought it'd be easier to remove if I did that. Not sure if that's helping.

Any suggestions? 🙁

EDIT: To clarify, the selector seems to be stuck between filament 1 and filament 2.

When I had this I had luck directly rotating the lead-screw with my fingers (power off, no motor disassembly) to get the selector shifted back over.

Neat, didn't think that'd be possible. Sounds like the selector motor isn't engaged in that state then. With my current track record, this info will probably come in handy. 😆

I managed to manually shift the lead-screw holding the tumbler back into position; the bearing actually wasn't making contact with the filament! There was very little force required to move the lead-screw. Filament is once again being retracted by the pulley motor!

This makes sense because I heard a lot of clunking sounds earlier; I guess something was preventing the tumbler motor from turning, which caused it to be offset.

Also, I think I need to re-evaluate how much I actually understand these stepper motors.

EDIT: In addition to manually shifting the tumbler back into position, you'll probably need to do a color change in case the printer is confused about where your filament is and begins underextruding (I calibrated my Bowden length earlier, so I'm not sure why this is an issue). If you do the color change, it seems like it solves underextrusion.