MMU 2.0 Filament Retraction Issue

Hello

I got the MMU 2.0 for my Mk3 last week, and assembled it that week. I then tried to print a 4 color model, but sadly no success so far.

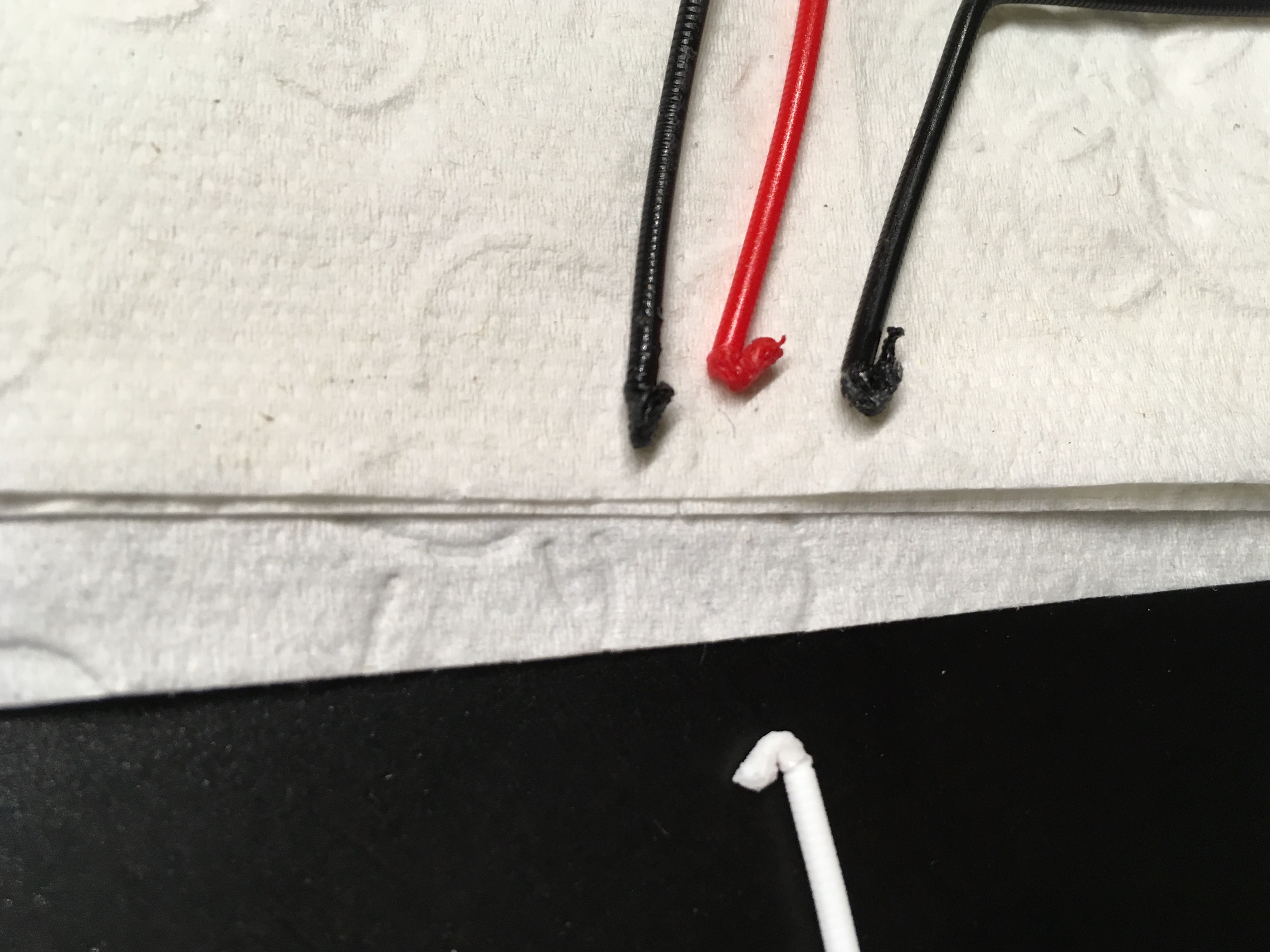

As soon as the second color retracts for the first time, it get's stuck just bove the hotend idler drive gears. I then have to manuelly pull the filament out. All filament look like this:

It looks to me as during retraction the hotend idler is pushing backwards, whereas the mmu idler is at a full stop, causing the thin part of the filament to clog the orange tube.

Has anyone else seen this?

I thought maybe my orange tube is too short, causing this. so, can anyone give me a measurement of the orange tube you have?

many thanks for your thoughts

Luke

Re: MMU 2.0 Filament Retraction Issue

did you do the Bowden length calibration?

I have a Prusa,therefore I research.

Re: MMU 2.0 Filament Retraction Issue

As soon as the second color retracts for the first time, it get's stuck just bove the hotend idler drive gears. I then have to manuelly pull the filament out. All filament look like this:

It looks to me as during retraction the hotend idler is pushing backwards, whereas the mmu idler is at a full stop, causing the thin part of the filament to clog the orange tube.

Well, something is mashing the end of the filament for sure. It's a good idea to do the bowden length calibration just in case, but I don't think that's causing this issue. The MMU should be completely disengaged when the extruder is backing out the filament, leaving only a little friction. If the MMU is engaged and fighting the extruder I could see how this might happen, but if that was the case I think you'd have bigger problems.

Just to eliminate some variables....What happens if you print a small model in single material mode? At the end of a single material print the MMU should unload the filament just like it does when changing materials. Do you see the same problem then?

Re: MMU 2.0 Filament Retraction Issue

@Luke173

I've had problems with my MMU2 as well.

Most were standard tweaking tensions and stuff like that.

Other issues were minimized using Prusa and Hatchbox filament instead of Inland filament (stringing leading to jams).

Still trying to get a complete print no layer skips.

Prusa MK3 > MK4s

Prusa MK2.5 kit > MK3 > MK3s > MK4s

Prusa SL1 3D printer + Curing and Washing Machine (day1 order)

Taz6 - taken apart for space

CR10s4 - upgrading

Delta 3ku - dont use

Re: MMU 2.0 Filament Retraction Issue

good day, many thanks for your thoughts.

Boweden Calibration: No, i didn't do this, how can I do it? I don't find it in the assembly manual.

Single color print: No, at the end of a print the filament does not unload back into the MMU here, it stays in the hotend idler. But it does not show any error from the machine at that point, so I have to assume it's the way it is.

I also thought about the material causing this, but it happens with every color PLA i have, and I don't really want to try ABS right now.

Thanks again

Luke

Re: MMU 2.0 Filament Retraction Issue

Single color print: No, at the end of a print the filament does not unload back into the MMU here, it stays in the hotend idler. But it does not show any error from the machine at that point, so I have to assume it's the way it is.

At the very end of a single color print the MMU should unload the filament. Is it not unloading the filament at all, or is it trying to unload and getting jammed?

If it's not trying to unload at all, then check to make sure you flashed the MK3 firmware with the MMU version, not the standard version. It's possible the printer has the wrong firmware.

Re: MMU 2.0 Filament Retraction Issue

Boweden Calibration: No, i didn't do this, how can I do it? I don't find it in the assembly manual.

It's hidden in the manual.

https://manual.prusa3d.com/Guide/Status+LED+indications+explained/762?lang=en

MMU2 Troubleshooting - Status LED indications explained - Step 4

Re: MMU 2.0 Filament Retraction Issue

When I follow that link, there are only three steps! Did they remove the Bowden length calibration?

Re: MMU 2.0 Filament Retraction Issue

https://manual.prusa3d.com/Guide/Service+menu+-+bowden+length/821?lang=en

that one should be it

I have a Prusa,therefore I research.

Re: MMU 2.0 Filament Retraction Issue

Many thanks for all your suggestions. I was able to adjust the bowden tube length to the right value, but no success so far.

It was suggested to me that the hotend PTFE tube could be damaged, so i will replace it and see how it goes.

Thanks

Luke

Re: MMU 2.0 Filament Retraction Issue

have you seen the posts about the gears in the mmu? seems they aren't all the same size, short story smallest on filament 1

I have a Prusa,therefore I research.

Re: MMU 2.0 Filament Retraction Issue

I have seen the Post about the Gear Diameters, thanks toaf.

I also swaped the hotend PTFE tube, it was suggested it could be broken (somehow).

So after all the fiddling, Bowden calibration, dance of the drive pulleys (smallest on filament 1) and exchange of the hotend PTFE tube, nothing changed. I still get the same blob at the end of the filament during retraction.

By now I re-flashed all firmwares several times, did the bowden calibration, and everytime I get the same result.

What else can I do now?

Many thanks for your thoughts

Luke

Re: MMU 2.0 Filament Retraction Issue

ramming stuff and temps would think, I don't have my MMU yet so I cant be much help. but the ramming is supposed to shape the end of the filament.

I have a Prusa,therefore I research.

Re: MMU 2.0 Filament Retraction Issue

I maintain an informal list of San Diego, CA 3D printing enthusiasts. PM me for details. If you include a contact email and I can add you to the informal mailing list.

Re: MMU 2.0 Filament Retraction Issue

Hi all,

I had the same issues, 100% retraction failure. Turns out my problem was that the Slicer settings I created were not correct. I originally just took the MK3 settings and enabled multiple extruders and saved as the MMU configuration. Sounds good, but boy was that wrong.

Eventually I ran the wizard and created the Prusa sanctioned MMU2 config, sliced with that and had immediate perfection! Not sure this applies to you, but it is worth a shot.

Re: MMU 2.0 Filament Retraction Issue

and you are correct about the extruder pushing back against the MMU.

It actually does that to help form the tip into a perfect shape and eliminate the blobs. But it has to do this in sync with the MMU extractor. Somehow this is all magically done in the config settings for Slicer. I think its called ramming.

Re: MMU 2.0 Filament Retraction Issue

I had the same issues, 100% retraction failure. Turns out my problem was that the Slicer settings I created were not correct. I originally just took the MK3 settings and enabled multiple extruders and saved as the MMU configuration. Sounds good, but boy was that wrong.

Did you try the bundled test print GCODE? I just finished setting my MMU up last night, and also had 100% failures on retraction, looked EXACTLY the same as the OP's pictures.

I calibrated the bowden (per the updated assembly manual). I attempted to print the 5-color gear bearing to make sure everything was set up properly, but it failed on the 1>2 transition. I cleared the jam and resumed printing, and it failed again on the 2>3 transition.

Tonight I'll try making new GCODE in the latest slic3r, since it's possible the Prusa GCODEs are old and don't work anymore with the rapidly evolving MMU2.

Any other suggestions?

Re: MMU 2.0 Filament Retraction Issue

I had the same issues, 100% retraction failure. Turns out my problem was that the Slicer settings I created were not correct. I originally just took the MK3 settings and enabled multiple extruders and saved as the MMU configuration. Sounds good, but boy was that wrong.

Did you try the bundled test print GCODE? I just finished setting my MMU up last night, and also had 100% failures on retraction, looked EXACTLY the same as the OP's pictures.

I calibrated the bowden (per the updated assembly manual). I attempted to print the 5-color gear bearing to make sure everything was set up properly, but it failed on the 1>2 transition. I cleared the jam and resumed printing, and it failed again on the 2>3 transition.

Tonight I'll try making new GCODE in the latest slic3r, since it's possible the Prusa GCODEs are old and don't work anymore with the rapidly evolving MMU2.

Any other suggestions?

the provided Gcodes work fine. there are lots of issues that exist that can obviously make it fail.

friction through out the system can make the Individual Filament Calibration wrong.

first by hand you have to insert filament and feel for obstructions in the different areas of the system.

a major problem is the current prusa Spool holder design. switch over to https://www.thingiverse.com/thing:3113520 this is a must have.

the friction of the original spools design will make the filament calibration pretty much impossible because it will change with each load and unload slipping on the pulleys.

you need to check for any filament catching in the extruder input down to the pulley. i spent over an hour with a round taper hand jeweler file shaping the cone from between the PTFE tube to around the sensor to the pulley i moved the filament all around and every time i felt it hit i went back and reshaped.

if the path from the spools to the extruder is as smooth as possible then the Filament calibration will be more stable and consistent. the pulley will miss less steps and it won't ram the filament into the extruder pulley and cause it to fold over jamming everything when it tries to push it down into the hot end.

now the filament itself has lots to do with this as well PLA is all over the place from being stringy or brittle, sticking, etc needing very different nozzle temperatures to function. having 2 brands in load 1 and load 2 where the temperature difference between the two is very different can cause big problems. if you want to be successful you may need to change to a different filament set that is all the same just to get started.

also you have to take it slowly, start with the printer as a single material to make sure things are functioning. bump up to 2 colors and have the system switch back and forth a nice quick way is use the first layer calibration it asks you to pick from the selector F1 -F5 and you can run this test over and over switching F1 to F5 manually and watch what everything is doing and you can listen for problems. i rammed up from 1 to 5 colors making changes as i found issues.

“One does not simply use a picture as signature on Prusa forumsâ€