Can anyone get the mk3s/mmu2s combo to successfully load soft TPU?

I'm having an issue when loading soft TPU (sainsmart & yoyi) with the mk3s/mmu2s combo. The filament becomes bound around the bowden gears in the extruder. Same problem at least 3 other people on the forum appear to be having.

So far I have done the individual filament calibrations on the mmu and the ir sensor calibration on the extruder. I can print from all 5 filament positions using hard filament (PLA and PETG) so everything appears to be functioning but I'm having no luck with even loading a single TPU filament.

Has anyone had any success in getting soft TPU to load with this combo? How about with the mk3s without the mmu? Is this a problem with the upgraded sensor? Is anyone having success with a mk3 with the mmu? I was able to get really good prints from the standard MK3 and I'm beginning to think that maybe I made a mistake by upgrading. Any help is greatly appreciated.

Best Answer by aychbe:

UPDATE: I was able to pinpoint another point of error that was causing TPU to bind in the extruder gears. My extruder pulley (the gear attached to the extruder motor) was less than 1 mm out of alignment with the hot end PTFE tube.

The reason why I was not having issues with PLA and PETG filaments binding in the gears is because the filaments are much harder and were able to redirect themselves into the PTFE tube. TPU is too soft to do this. It would load correctly on the first load because of the freshly cut angle at the end of the filament. The next few loads would also be fine because of the tip of the filament being relatively pointy from the ramming. After about 5 machine changes, I noticed that the filaments were wrapping around the gears in the extruder, even with the idler screw almost completely out. Upon close inspection of the way the filament had bound itself around the pulley gear, I decided to adjust the pulley a very small amount. The current print job I'm running has been going for around 12 hours with zero load/unload errors, filament binds in the extruder gears and (as far as I can tell with the print still underway) no skipped layers.

I am much more optimistic about the "S" after figuring this out. Hopefully it's as reliable as the mk3 was!

So if you're able to print using the MMU with harder filaments like PLA and PETG but are unable to load TPU properly, first make sure the extruder pulley is aligned properly. Then calibrate the IR sensor (1 means filament is present, 0 means there is no filament). I'd recommend using a piece of PLA filament instead of a hex wrench because you'll have an idea if the idler screw is set properly if you're able to manually insert filament into the gears.

RE: Can anyone get the mk3s/mmu2s combo to successfully load soft TPU?

Had you gotten the filament to work with the MK3S by itself before adding the MMU? I tried NinjaFlex once, had no success, and didn't understand much of what people were telling me to do. Now that I know more, I just haven't gotten back to it.

The gist is that things need to move really slow for TPU. I know there are bunch of settings for the extruder, but I don't know how much control you can have for the MMU's drive motor. If the MMU is pushing it faster than the extruder I could see that causing the mess you are experiencing even if you have the extruder tuned right.

RE: Can anyone get the mk3s/mmu2s combo to successfully load soft TPU?

I did the mk3s upgrade at the same time as adding the mmu2s so I have not attempted to do it as a standalone. I'll give that a try.

As far as I can tell, the mmu load is correct. I've calibrated the filament lengths to be just above the center of the extruder gears. The filament "rams" from the mmu to the extruder, slowly steps into the gears, the gears ingage and then it pulls about 15 cm into the gears, wrapping around the bowden gears, before the mmu attempts to back out the filament. I will get TPU oozing from the hotend so it does make it into the nozzle. Since there is no indicator light visible on the extruder's IR sensor, I'm beginning to think that this may be the culprit.

RE: Can anyone get the mk3s/mmu2s combo to successfully load soft TPU?

Ok, bypassed the mmu and I'm able to load/print TPU with the mk3s hardware.

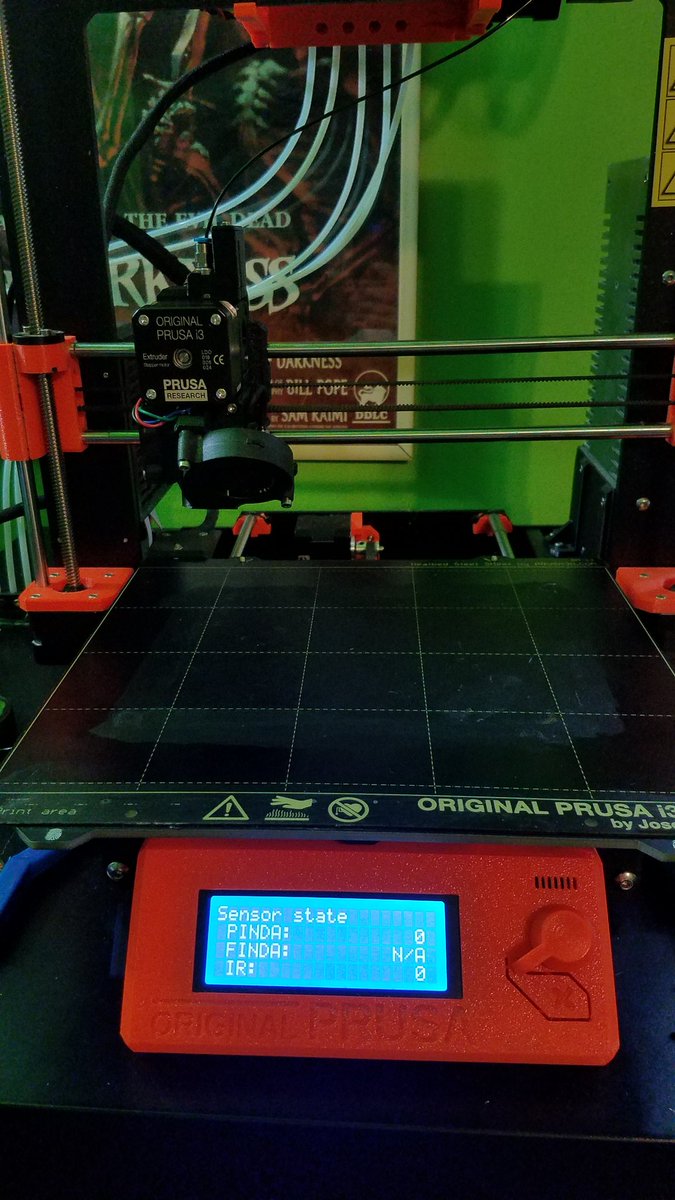

Here's an image:

Notice that the filament is loaded. I could upload video of the printer printing as well, but note that the IR sensor is showing "0" which means it is not detecting the filament.

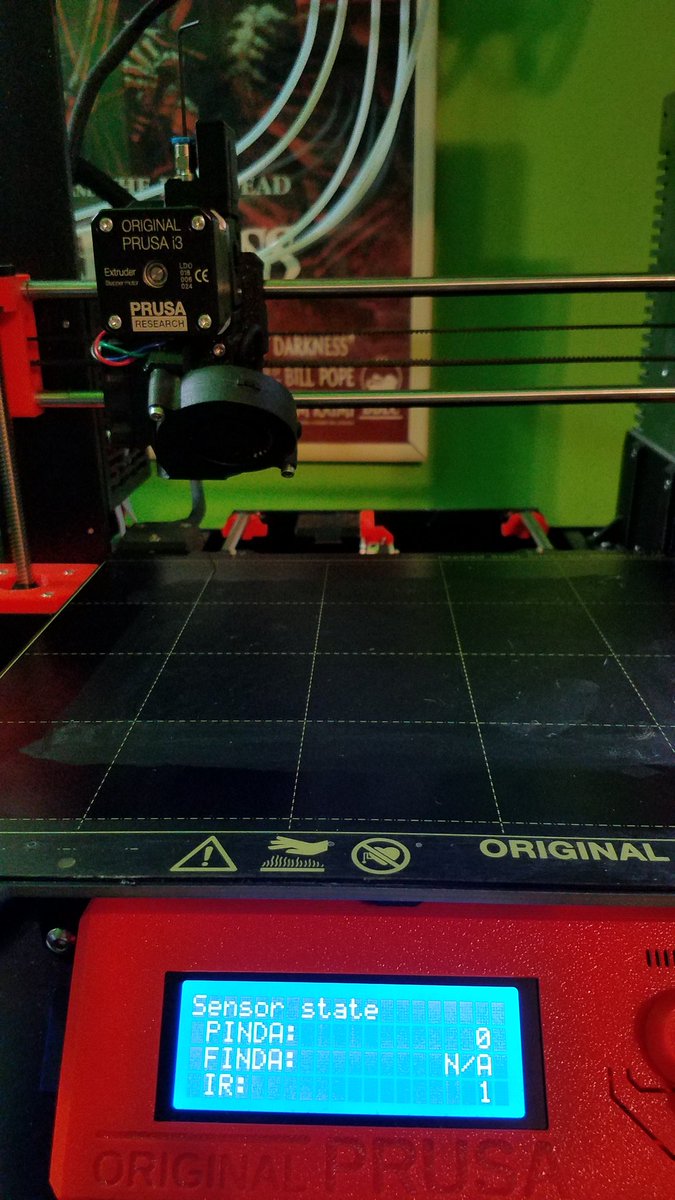

Here's a second image showing the hex key IR calibration:

Note that it is showing that something is present.

So this issue is with the "upgraded" (and I call it an upgrade in the most loose sense) IR sensor. I'll run the single print color using the mk3s hardware only so at least I can get my objects printed. I will contact Prusa to see if they have a solution for this issue.

Please, if anyone has figured out how to get TPU/soft FLEX to trigger the IR sensor on the mk3s, let me know. If anyone has had a successful TPU load and print using the mk3s/mmu2s combo, please let me know how. If I hear anything from Prusa on how to get this working, I'll post it here.

Apologies to the board admins if this is a misplaced topic.

RE: Can anyone get the mk3s/mmu2s combo to successfully load soft TPU?

it does work with the "S". sorry it took so long, I had other things to print. copy the setting for it from mmu single mode into a new mmu filament. don't forget to turn off Z hop

bumer.. it doesn't play gif files..but its flexible

I have a Prusa,therefore I research.

RE: Can anyone get the mk3s/mmu2s combo to successfully load soft TPU?

it does work with the "S". sorry it took so long, I had other things to print. copy the setting for it from mmu single mode into a new mmu filament. don't forget to turn off Z hop

bumer.. it doesn't play gif files..but its flexible

@Toaf, I'm sorry but I don't follow what you're saying. What settings are you saying to copy?

For TPU I already have retraction and Lift Z set to zero in slicer. I'm having an issue where the filament reaches the extruder from the mmu but ends up binding about 15cm of filament around the extruder gears.

RE: Can anyone get the mk3s/mmu2s combo to successfully load soft TPU?

sorry, I didn't see your post. "I miss the old someone posted on your post" thing the old forums had.

this is my latest flex filament settings. I think that alone should be a good hint. it is not optimized but it worked. hopefully I wasn't playing around the last time I saved it. I have setup my damned flex filaments at least 6 times now. but that's what happens when I was using all the betas... my poor saved settings.

I have a Prusa,therefore I research.

RE: Can anyone get the mk3s/mmu2s combo to successfully load soft TPU?

and don't forget to loosen the tension on the extruder bontech

I have a Prusa,therefore I research.

RE: Can anyone get the mk3s/mmu2s combo to successfully load soft TPU?

@john-h76 for your IR issues, 0 is what you want it to show when filament is present. It's backwards from what you would think given the purpose.

How big of a hex key did you use to calibrate? If it is not roughly the size of filament then it might not trip the sensor.

Since you hadn't been printing with the MK3S yet, I'd suggest falling back to just printing with PLA to start right now. Get it reliably printing with the IR sensor enabled, then try the TPU.

Take a look at my other posts (sorry, on my phone right now) for my comments about the idler door and IR sensor and see if any of that applies/helps.

RE: Can anyone get the mk3s/mmu2s combo to successfully load soft TPU?

Sorry, but this is not right.

The IR sensor value goes to 1 if it got triggered by filament sitting between the two bondtech gears.

You can even try to trigger it by the use of some PLA filament instead of the hex key.

I would guess, in this case the spring loaded screw for the bondtech gear is just too tight for TPU. Loosen it a bit as mentioned by toaf.

Trying without MMU could help at least to find the right adjustment for the screw.

RE: Can anyone get the mk3s/mmu2s combo to successfully load soft TPU?

@john-h76 for your IR issues, 0 is what you want it to show when filament is present. It's backwards from what you would think given the purpose.

RE: Can anyone get the mk3s/mmu2s combo to successfully load soft TPU?

Say what?

IR reads 0 when it's triggered, and 1 when it's not? No, that isn't right. You're thinking of the PINDA/FINDA sensors.

(PS. This has to be the worst Forum software in the history of Forum software... Try replying with a quote on an Android phone. It's bloody impossible!)

RE: Can anyone get the mk3s/mmu2s combo to successfully load soft TPU?

P.p.s. this extruder IR sensor setup is poorly designed. It needs something other than physical idler movement during engagement. It's not easy, but maybe a piezo force sensor or something ..

RE: Can anyone get the mk3s/mmu2s combo to successfully load soft TPU?

P.p.s. this extruder IR sensor setup is poorly designed. It needs something other than physical idler pivot movement during engagement. It's not easy, but maybe a piezo force sensor or something ..

RE: Can anyone get the mk3s/mmu2s combo to successfully load soft TPU?

P.p.s. this extruder IR sensor setup is poorly designed. It needs something other than physical idler movement during engagement. It's not easy, but maybe a piezo force sensor or something ..

@kieran.s4 Well said. The IR sensor is the center of the problem with the MMU. It's inconsistent and nearly impossible to get a working calibration for multiple materials. Hell, I can get a proper TPU load about 50% of the times with the same filament. I highly doubt there's a huge inconsistency with the filament width, as I had been printing flawlessly with them using the mk3.

To add to the issue with using the idler to detect the filament, I ran into an issue with the IR sensor moving slightly because of the m2 screw on top of the IR chimney not being tightened enough. The wires would move slightly as the extruder head moved and when it came time to unload and then reload, the sensor was already out of calibration.

And for final clarity, the IR sensor shows 1 when filament is present and 0 when there is no filament. If you load filament to the mmu but the filament never makes it to the extruder and you get the "Is the filament the correct color" message on the led screen but there is no filament in the hotend, your IR sensor is likely showing a false positive (1) and you need it to read 0.

RE: Can anyone get the mk3s/mmu2s combo to successfully load soft TPU?

Thanks everyone for the help! I am able to load TPU successfully about 50% of the times, which sadly is about what I've come to expect from the MMU at this point. Maybe there's some fine tuning that can be done so I can finish an entire 9 hour, 2 color print of the sample sheep file in less than 24 hours (because of load/unload errors).

@toaf Your filament settings are nice! I'm definitely going to use them for a single color TPU print.

My issue was the result of the IR sensor being, and I'm trying to be objective, difficult to calibrate for consistent results using TPU. It kind of works with PETG and PLA but overall, I'm not a fan of the "S" currently.

RE: Can anyone get the mk3s/mmu2s combo to successfully load soft TPU?

UPDATE: I was able to pinpoint another point of error that was causing TPU to bind in the extruder gears. My extruder pulley (the gear attached to the extruder motor) was less than 1 mm out of alignment with the hot end PTFE tube.

The reason why I was not having issues with PLA and PETG filaments binding in the gears is because the filaments are much harder and were able to redirect themselves into the PTFE tube. TPU is too soft to do this. It would load correctly on the first load because of the freshly cut angle at the end of the filament. The next few loads would also be fine because of the tip of the filament being relatively pointy from the ramming. After about 5 machine changes, I noticed that the filaments were wrapping around the gears in the extruder, even with the idler screw almost completely out. Upon close inspection of the way the filament had bound itself around the pulley gear, I decided to adjust the pulley a very small amount. The current print job I'm running has been going for around 12 hours with zero load/unload errors, filament binds in the extruder gears and (as far as I can tell with the print still underway) no skipped layers.

I am much more optimistic about the "S" after figuring this out. Hopefully it's as reliable as the mk3 was!

So if you're able to print using the MMU with harder filaments like PLA and PETG but are unable to load TPU properly, first make sure the extruder pulley is aligned properly. Then calibrate the IR sensor (1 means filament is present, 0 means there is no filament). I'd recommend using a piece of PLA filament instead of a hex wrench because you'll have an idea if the idler screw is set properly if you're able to manually insert filament into the gears.