1 week to get my MMU2s working or I'm returning it and my Mk3s+

There seems to be hundreds of stories online in all the community forums of people regretting their purchase of the MMu2, I really wanted it to work. I bought the MMU2s and the Mk3s+ together, I still really want it to work. To me working is 99.9% success rate in switching filaments, I was at ~95% at one point, and now I'm at ~70%. I’m very happy with my Mini+, and I knew this would be hard to get working but it's getting to be too frustrating. I’ve spent almost every day since June1st trying to get it working, all of my time searching these forums and youtube videos and endlessly tinkering and it keeps finding new ways to fail. I’m really disappointed and feel like I’ve wasted almost 2 months of my life being an unpaid guinea pig / test subject.

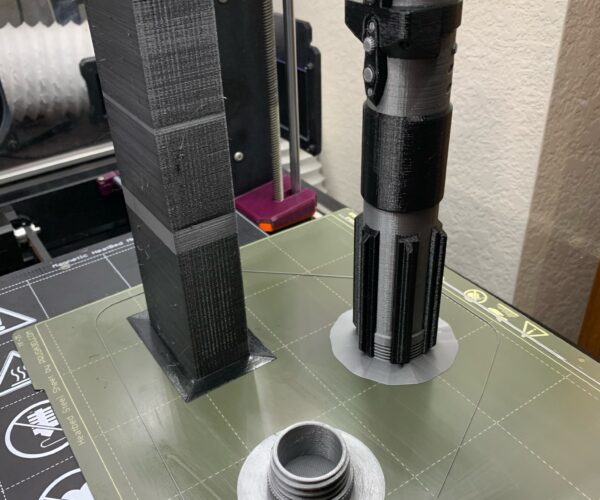

here is the link to the latest 3mf file I've been trying to print https://drive.google.com/file/d/1s2K1OAlsBQDS6CMynoNLTBYZf3O8JbWH/view?usp=sharing

here are the mods I've installed:

- TZB extruder v3 assembly (seems this has solved the IR sensor, I don't have problems with the IR actually, only issue down there is when the filament is cut flat and the gears won't grab it, but that is probably same with stock) https://www.prusaprinters.org/prints/66215-tzb-mk3smk25smmu2s-extruder-mmu2s-no-tower-v3

- I tried the TZB firmware but found I had less issues without it

- all PTFE tubes behind MMU2s and between it and the extruder replaced with 3mm inner diameter tubes

- the rear ptfe holder upgraded to https://www.thingiverse.com/thing:3233579

- I currently have all my filament on a smooth dowel a couple feet away from the MMU2. They spin easier than the spool holders that came with the setup. I have partitions in between the spools so the filament doesnt cross between them. There is no drag between the spools and the MMU2

- I bought and printed the RMU mk3 buffer (definitely regret) https://filamentbuffer.co.uk/ , could've been my print settings but it just added more drag so i've had my best luck with no buffer at all and lots of space in between the spools and the mmu2a new selector with magnet and window

- the MMU idler and rewind spool holders are on my list to print, but I shouldn't need them to get it working initially, thats something I can do after a few months

- I've changed much of the printer/filament settings based on different youtube videos i've seen. I can't list them off the top of my head beyond increasing cooling moves and ramming, hopefully you can see the settings in the 3mf file

Latest problems:

- tips so thick they get stuck in the selector on the way back the MMU gears grinding filament or not grabbing it at all is a huge problem. the screws are either too loose or too tight, i spend forever adjusting turning by 1/4 rotations, and it just always seems to be an issue. This latest is with prusament too, the other amazon filaments have less problems actually.

- Extruder has been clicking and squeaking

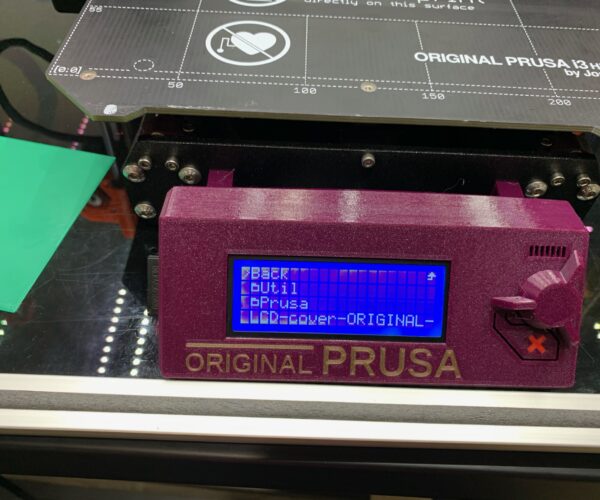

- too often the mmu2 thinks the selector is in a different place than it is, and its extremely annoying trying to reset it or tell it to load another filament to get it to line up correctly again

Thanks in advance yall... I do believe in 3d printing, open source, community based technological advancement, etc.. I want this to work but I’m pulling my hair out and I'm days away from giving up on multi material printing entirely. I cant spend another few months tinkering with the MMU only to disconnect it later. My warranty ends in 2 weeks, and i only have about 5 days in between then and now to try and get this thing reliable before I totally give up and return it

Eshop

My recommendation is the you work with support. There is a Chat button on the eShop.

--------------------

Chuck H

3D Printer Review Blog

title

Yes, contact support chat in the eshop. The chat button should show up in the lower right corner (you may have to log in first and some times disable your adblocker if you use it)

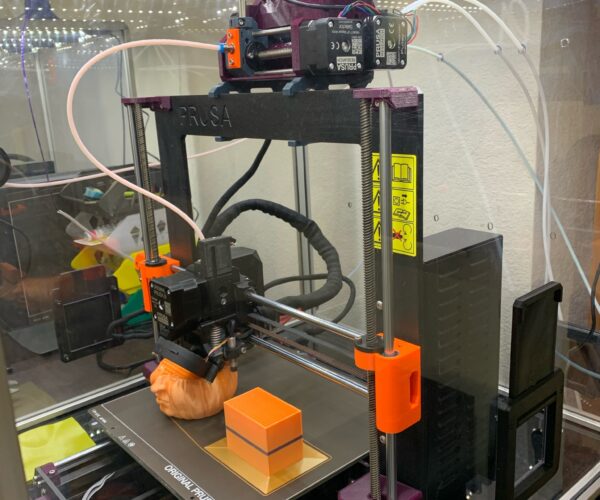

That MMU can definitely work. Mine has been doing fine after a few day to set things up. I have done a print a few times now that takes a little over 24 hours with over 750 filament changes. And most with no errors or just one or two that could be easily solved and resumed printing.

I also use the TZB v3 extruder with the latest Prusa firmware. But only picked this extruder as the chimney on the original got in the way on tall prints on my setup.

And use the selector with the magnet mod. Not sure if that changed anything, as I haven't used the original selector on my MMU.

All default settings for ramming and cooling. I only use higher temps on the MMU. The default profiles lower the print temps with using the MMU compared to using the MMU in single mode.

There is one video that has helped me understand the MMU better. When you understand what it is doing and when, it helps troubleshooting.

But as you have spend a lot of time already I would contact support. That is what you have paid for.

support

Support helped me the final piece the puzzle fit in to place. This was the extruder idler bolt being too tight.

This beast can be tamed(to an extent).

I just finished a 2d print with 1706 filament changes and had only one intervention.

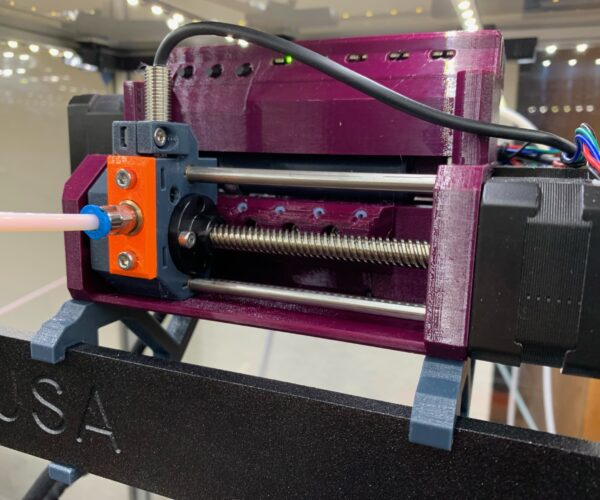

Having worked through most of the failures with this thing I'd say really the only require mods to it are the M10 PTFE pass-thru and the horizontal mounting of the mmu. The above print is PETG which has generally been the problem child for me due to strings.

I was confident after getting to the mmu working to reprint the parts in different colors.

I most certainly don't use the buffer.

My most recent arrangement has been the most reliable. There's enough slack to absorb the filament as it's retracted from the extruder. The sunlu dryer boxes work great for keeping filament from jumping off the spool and they can be plugged in to dry filament while it's printing.

I'm fairly tenacious when it comes to chasing down a problem, but I was very nearly ready to give up too before I talked to support and they pointed out that I had my idler bolt too tight. Other than reprinting the parts in different color since I talked to them, all my parts are stock except for the ptfe pass-thru and the horizontal mounting brackets. Good luck!