Upgrading my two MK3S to MK3S+ with Bondtech Mosquito and SE Copperhead Shortcut

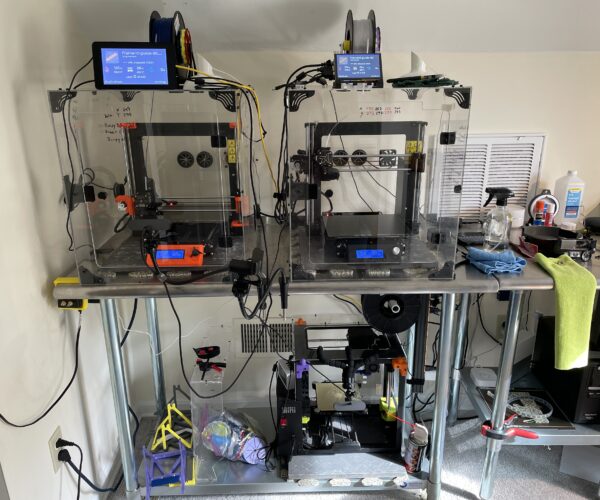

I have two Prusa MK3S printers (Orange/Black) that I will be working on.

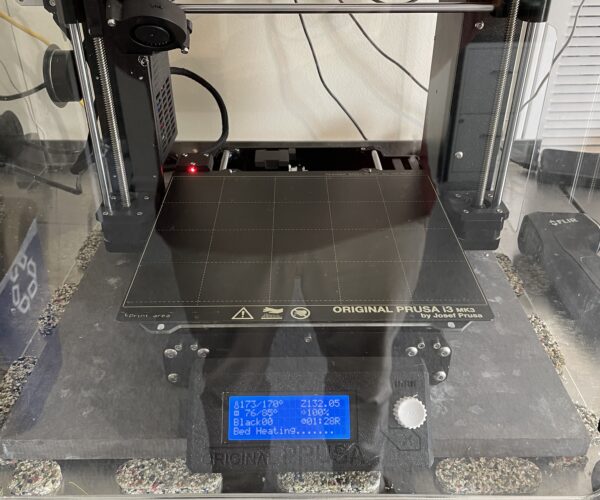

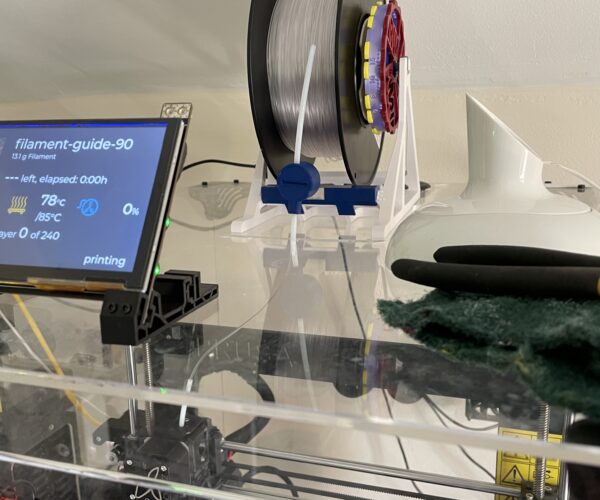

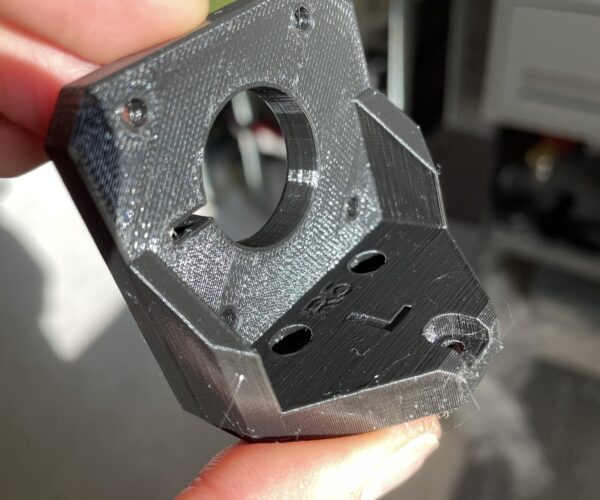

I have already upgraded my Black with new Misumi rods and bearings, belts, new Zaribo steppers, and the printer updates to X,Y,Z for the MK3S+ upgrades. The new rods and bearings were for my Y axis crashes caused by poorly lubed bearings. The machine was also pretty noisy. After the new rods and bearings were installed I decided to try the Nylock Mod. My bed is so level now it's not even funny. If you have issues with your bed I suggest you try it, it is very easy to do and does not take a ton of time. If you take your time and be careful with your leveling you will have a flat bed. The big upgrade will be the Bondtech LGX extrude with a SE Mosquito hotend. I can't complain to much about my original from Prusa but I wanted to see if I could level up with the new extruder and HE. I just got a message from Bondtech saying it has shipped. I have been waiting almost a month, which is why I have not done that upgrade yet. I will try to get some good pics and video when I install and print.

I do want to mention these two things: The Nylock is awesome especially if you have bed issues and make large prints. Also, lubricating the bearings is essential for the rods, bearings, and smooth quiet travel. Even if you don't replace them, take them off and pack them again.

I started the mods with the Black printer but the Orange will get the same treatment. I did not have the Y axis crashes with the Orange but it did have some noise that I wanted to damper. This printer will get the same treatment as the Black printer but I will be adding Bondtech LGX extruder with a SE Copperhead Shortcut. This is a hotend that is very short and is a more direct route from extruder to hotend. This is supposed to greatly improve printing with soft materials. I can print Ninjaflex and Cheetah fine with the Prusa extruder. Both of those materials are firm enough to get through the extruder. Some hiccups but I do well with those two but Chinchilla I cannot get to print. All three of those materials are in the TPU/TPE family. Cheetah is nice, easy to print, and tough. Ninjaflex can be tougher to print and is more flexible. Chinchilla is really soft and I have not been able to print anything out yet. I do like the soft materials as they come in handy for some projects. But I digress. I am looking forward to the new hotend to see if the soft materials are easier to print.

I would love to try to upgrade the X, Y, Z to get a bigger volume. I have looked at a few upgrades but they mostly address the Z axis. I have have to make my own frame and find a bigger bed.

before / after pictures

please, take some pictures of the same print with the original Extruder and as comparison with the LGX Extruder, printed in standard materials like PLA, PETG, ...

I would like to know, if there is a significant quality improvement when printing non-flexible standard material.

Before and After

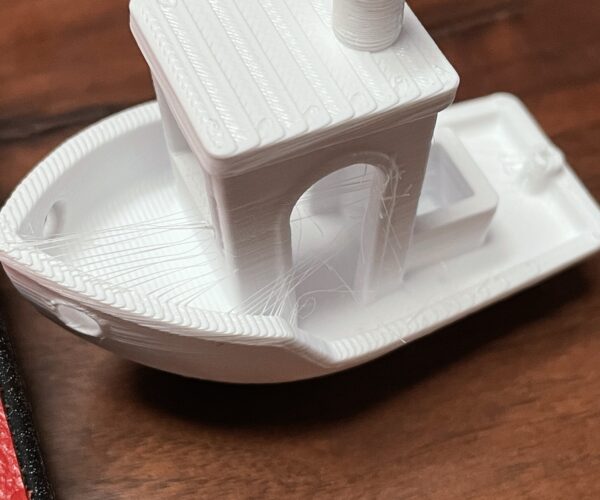

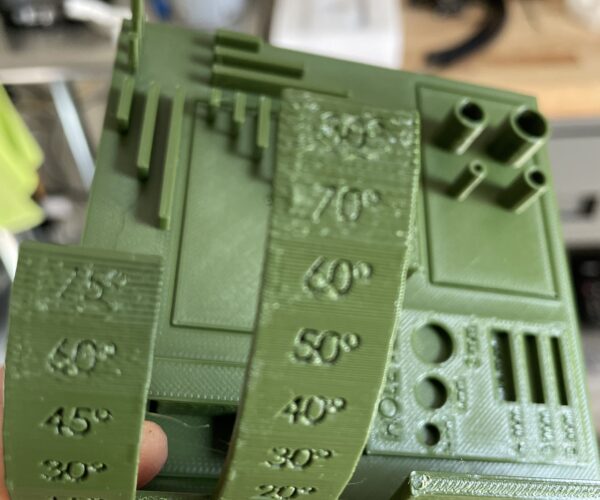

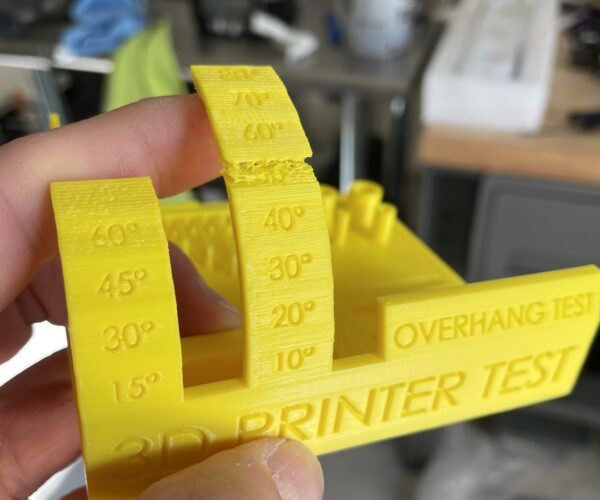

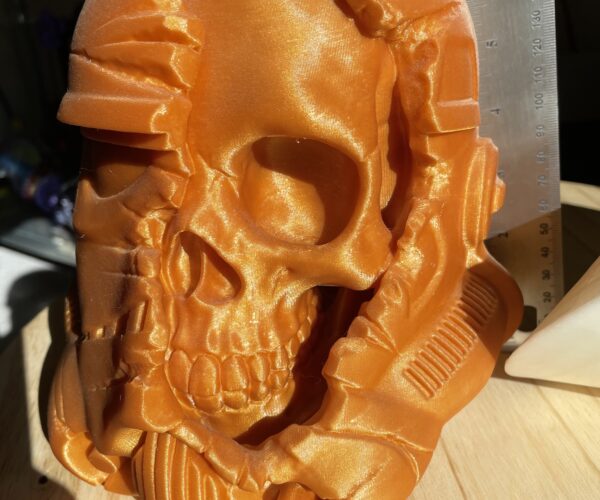

@stefan I will upload some images today of my current Prusa stock extruders and E3D hotends prints. I think I can find a few torture tests. If not I will print out a torture test. If you have one in mind let me know. I have a million Benchy's and cubes but I dont think that will be a good comparison. I will add some of my non torture test prints. Both of my printers do pretty well. The biggest issues I have are with ooze at the start which was ruining prints. I fixed that with a Gcode fix. It just waits to heat the hotend until after the bed level. I will be curious to see how much if any difference shows. As far as PLA/PETG they both do well, PETG just has the stringing but that can be fixed with temps/cooling and retraction.

pix

Prusas forum image deal is not great. Hopefully the pictures and video show up.

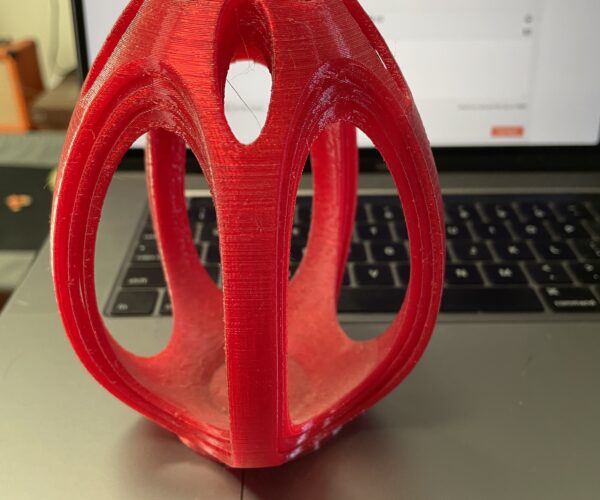

makers muse torture teIMG_5702st

print quality

your print quality already looks very good to me 👍

the LGX extrudes will certainly be a advantage for printing flex material, but i would not expect it to make a visible difference with PETG / PLA. But maybe there will be a surprise ... 😀

print quality

I will say that the Prusa's I have are very consistent. I have had issues here and there but nothing to crazy. One pain, for me, is the belts. Takes me sometime to get them at the right tension. That's only when I do something with the extruder though. I wanted to do a project so I thought I would try some different extruders. The other upgrades MK3S-MK3S+, rods and bearings, belts were beneficial. I did the steppers but I wanted to see if I could cut noise. They are a bit quieter. Not really beneficial unless you find some super fancy ones maybe. With the parts I want to make another 3D printer from scratch. I want to try a Duet board but I'll have to study up.

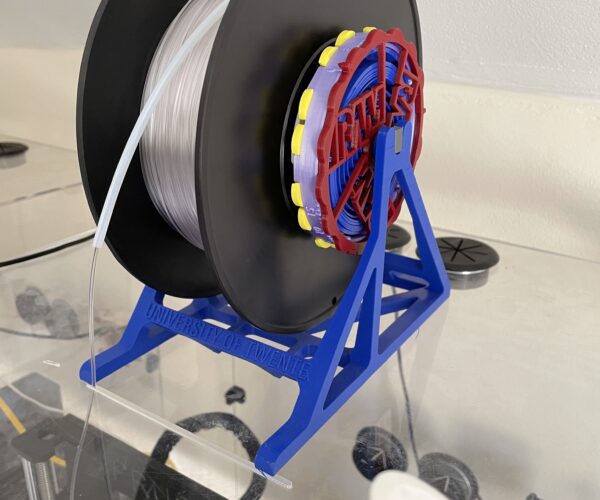

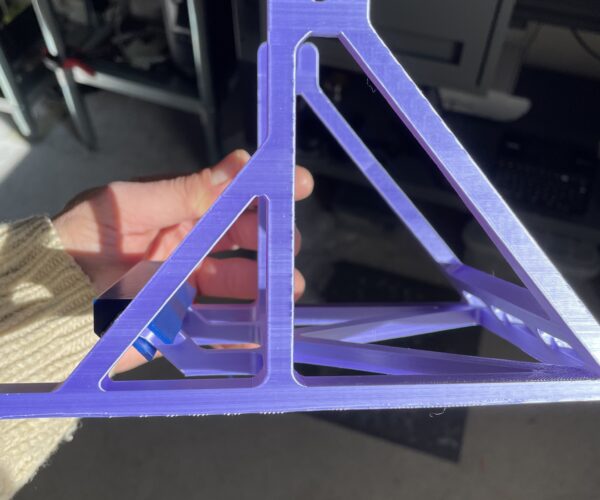

pics of the 3d printer setup

I don't know if the pictures are showing. I wanted to show the printer sitting on the rubber mat and the paver. This setup made so much difference in the noise.

ASA and Colorfabb XT

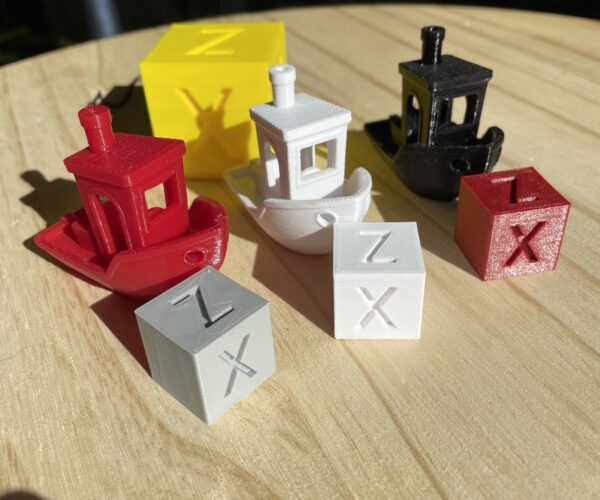

The black benchy is ASA printed with Prusa's default settings. Man, it is really beautiful, the pix look like I was too zoomed in so some of the imperfections I think are my camera skills. The white benchy is Colorfabb XT with Prusa defaults. I printed on the satin sheet no prep. The XT had some strings but it would be an easy fix and the discoloration on the bottom is a little blue petg left over.

which extruder?

the black ASA benchy ist printed with the stock extruder or already with Bondtech?

RE: Upgrading my two MK3S to MK3S+ with Bondtech Mosquito and SE Copperhead Shortcut

Sorry about that, it's all stock. I wanted to get as many filaments in as I could. In the older images there is PLA, Ninjaflex, PET-G. I printed with Cheetah, which is a Ninjatek product tougher and easier to print than Ninjaflex, I think it was included. The stock extruders do well. The two new images were my first time trying the high heat stuff. The ASA benchy is really nice, I don't think the first pic looked good but that was the camera. The finish on it is really appealing to the eye.

RE: Upgrading my two MK3S to MK3S+ with Bondtech Mosquito and SE Copperhead Shortcut

Have you upgraded extruders yet?

RE: Upgrading my two MK3S to MK3S+ with Bondtech Mosquito and SE Copperhead Shortcut

Nice prints!

I like the Mosquito a lot, especially for the one-handed fast nozzle changes. Aside from going through a couple of heaters and a thermistor, neither of which is the Mosquito's fault, it's been great for a year or so.

So far as exotic steppers, there are a few choices. For stock firmware, it is necessary to use 1.8º stepper motors. the Moons MS17HD2P4100 or possibly the Trinamics QSH4218-51-10-049 have some recommendations as improvements over the standard LDO motors, though the Trinamics is larger and heavier and not well suited for extruder.

If you want to live on the edge and dabble with the firmware, 0.9º stepper motors are regarded to have better resolution. The Moons MS17HA2P4100 in particular is well regarded. Note that the part number is only one digit (A vs D) different than the 1.8º motor, so don't order the wrong one! All of this about steppers, by the way, is covered in this Forum elsewhere by a very dedicated member, Bunny Science.

¡no entiendo Español!

Nein! Nicht Versteh!

Я немного говорю по-руÑÑки но не очень хорошо, и...

I'm not very good at English either! Maybe someday I'll find a language I'm good at?

RE: Upgrading my two MK3S to MK3S+ with Bondtech Mosquito and SE Copperhead Shortcut

I'm almost ready to push the order button for the shortcut.

I have read a few posts about heatcreep, is your LGX still going strong with PLA? Any issues?

RE: Upgrading my two MK3S to MK3S+ with Bondtech Mosquito and SE Copperhead Shortcut

I am very very happy with the LGX. I think it is a really good extruder. It pulls the filament nice and evenly and it grips even the softest filament. I can print Ninjatec Chinchilla which is super soft. The shortcut, in my opinion, is not a super change from stock. I do think it has better heating, even, and I can drop temps a little bit if I need to and it still works great. I am happy with both the Mosquito and Copperhead. I need to print some crazy stuff like nylon and asa but PLA, PET, Ninjaflex, etc. work well.

RE: Upgrading my two MK3S to MK3S+ with Bondtech Mosquito and SE Copperhead Shortcut

I am so servo incompetent. As an ADHD guy I feel like if I take too deep a step into servos it will end up an entire hobby. I will check out the steppers you mentioned. Sorry for the late reply. I lost my 2 factor so it took a while to get in. I want to build a reprap. Basically a prusa but maybe 300-350mm x 300-350 x 270mm. If I get around to it I will try it out. thanks for the info

RE: Upgrading my two MK3S to MK3S+ with Bondtech Mosquito and SE Copperhead Shortcut

I don't print too much flexible. I have one roll Polymaker flex. That's it.

Will be using this extruder for PLA/PETG/PCCF

I have a Mini Bear and have been using the stock Mk3 extruder for awhile, but got a case of issue 602. Now working with a Orbiter V2, which is better.

But i'm wondering if there is enough room on the x-axis for the whole width of the bed, when looking at the extruder is has both fans on the side. Does that fit well?