pre-compiled firmware?

I'm giving up. Had hard enough of a time compiling firmware for my SKR Bear, this Arduino thing, I'm just lost.

Would someone be able to share their precompiled firmware(.hex) so I can flash and try the set up? I'm using LDO 0.9 on X and Y.

Thanks!

RE:

OK, here are some findings about various stepper motor combinations on a Mk3s

Standard Prusa / LDO steppers: Standard results. The VFAs are present. Really, they are relatively minor. This was checked using a Mosquito hotend. Keep in mind that Prusa has extensively tested these motors and have optimized everything possible to use them to maximum advantage.

Moons MS17HD2P4100 steppers installed on X and Y axes. - VFAs reduced. Occasional high pitch squeal / resonance on diagonals, particularly on short rapid movements. The Moons steppers do run considerably cooler than the standard Prusa / LDO motors. They are also a bit quieter, especially on slow movements, not so much on full speed movements.

Moons MS17HD2P4100 steppers on X, Y and Extruder. An unexpected considerable improvement in print quality noted. Apparently the Moons stepper is a considerably better choice for the Extruder than X and Y. The difference is more pronounced that the X and Y axes. As the Moons runs considerably cooler and is very slightly lighter than the Prusa / LDO extruder motor, this one is a keeper, and would be my first choice for a Moons replacement.

Moons on X,Y and E with an E3D Revo replacing the Mosquito. Surprisingly little difference, maybe a bit less stringing. A really nice Benchy in PETG was printed.

Trinamics QSH4218-51-10-049 stepper motors on X and Y, the Moons on Extruder. The Trinamics motors are designed with micro stepping in mind and also specifically for use with Trinamics stepper drivers, which the Mk3 series uses. As they were available quickly from Digikey in the US, I gave them a try, not expecting much.

I was pleasantly surprised! The Trinamics QSH4218-51-10-049 run smoothly and quietly, more so than the Moons with the same reduction in VFAs. On the other hand they are considerably longer and heavier, making them a poor choice for the Extruder. Also, they do run a bit warmer than Moons, but still cooler than Prusa / LDO. The permanently attached leadout wires are a bit short at 300mm, which is just barely long enough for X and Y with a little re-routing.

Some relevant data:

Having cleaned up my prints a fair bit, the next glaring characteristic is becoming obvious.... the "Polygon Effect" on the Y axis which is now clearly visible as 2mm spaced vertical artifacts. Inspired by Prorifi's kit and website, I have been working on a phase-shifted Y axis belt drive, which will be my next update to this thread, I hope.

All in all, The standard LDO motors do well. If one is budget conscious, just stay with them.

For the best effect, I would use a Moons on the Extruder. This seemed to make the largest, though still relatively small difference. The cooler running can be an important factor on long prints with low temperature filaments.

Rather than use Moons on the X and Y axes, I would go with the Trinamics. Perhaps the QSH4218-51-10-049 is a bit overkill. The QSH4218-41-10-.35 is weaker at 0.35Nm holding torque but the same dimension and weight as the LDO and Moons.

Prorifi, who posted earlier in this thread has complete kits available with motors and a Y axis pulley system designed to reduce these effects.

As Prorifi's site mentions an 8-week lead time, I decided to not try them yet though I would like to. Perhaps I will order from them and see what develops.

Happy Printing!

¡no entiendo Español!

Nein! Nicht Versteh!

Я немного говорю по-руÑÑки но не очень хорошо, и...

I'm not very good at English either! Maybe someday I'll find a language I'm good at?

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

Have anyone ever thought about using two motors on the X-axis? One left and right? This should also simply approach this with a simple stepper series switching. For other manufacturers I have already seen that. You should actually only replace the right z-slide by mirrored left.

RE:

Hi all, just found this so jumping in.

I have an original Prusa MK2 I just upgraded to an MK2.5s using a Prusa kit. Everything works but now I have really bad surfaces and persistent vertical lines (VFA)? The printer was great until the upgrade. I am running tests to see if this is more of a Y axis issue or if it is both X and Y equally.

Most things I have read up to this point indicate that the main problem comes from the steppers. If this is really the case why did the problem only show up after the MK 2.5s upgrade?

What do you guys think?

I can change to better steppers but only if it will actually make a difference!

Thanks for any ideas or thoughts and sorry to bring an MK2.5s to the MK3 forum!

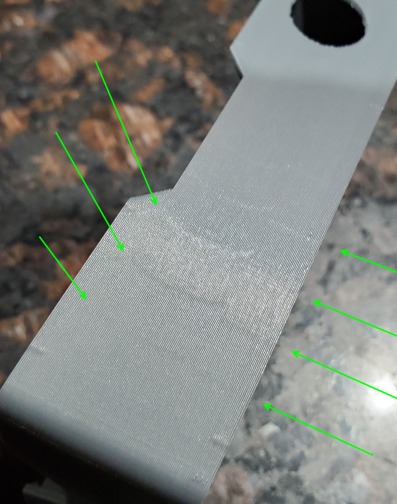

Pictures are of my test part and also one to show the orientation of the part on the printer.

RE: Stepper Motor on Mk2.5s

Unlikely to be the steppers unless one or more failed.

The Mk2.5s still uses the MiniRambo and its older driver hardware. Essentially, most of the motion and control systems are unchanged from Mk2s to Mk2.5s. More likely something else happened during the upgrade... perhaps the heavier heatbed or perhaps the extruder? Or maybe some of the linear bearings didn't like being disturbed?

The Vertical Fine Artifacts that we are foolishly chasing in this thread are, well, fine, that is to say very minute. The printer has got to be performing extremely well before they are even noticeable as nearly anything else will mask them. By all accounts, only perfectionists or curious experimenters would waste the time and money needed to change out perfectly good steppers for ones that might, at best, offer only very slight improvements.. particularly if one sticks with 1.8º steppers as I have.

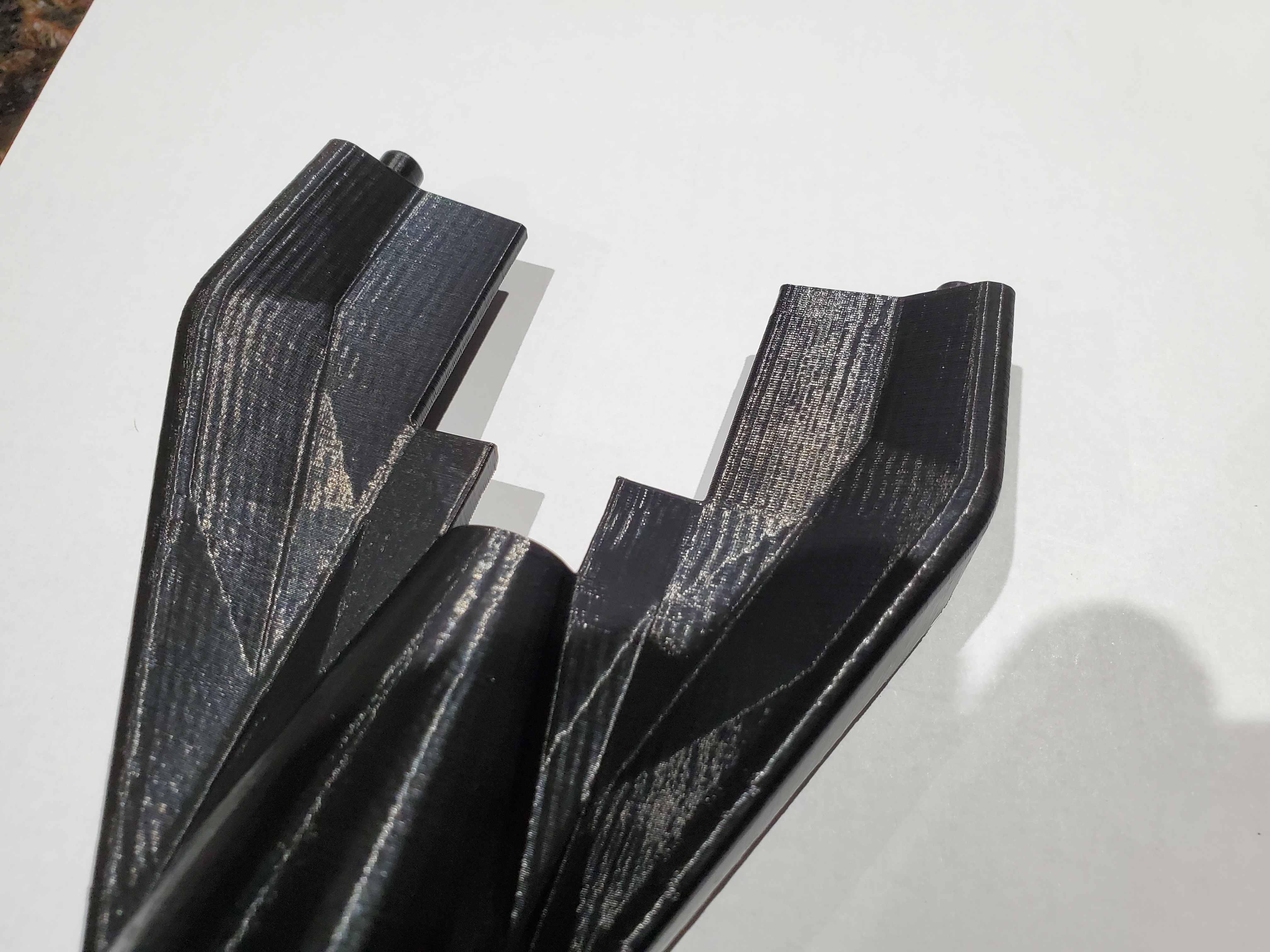

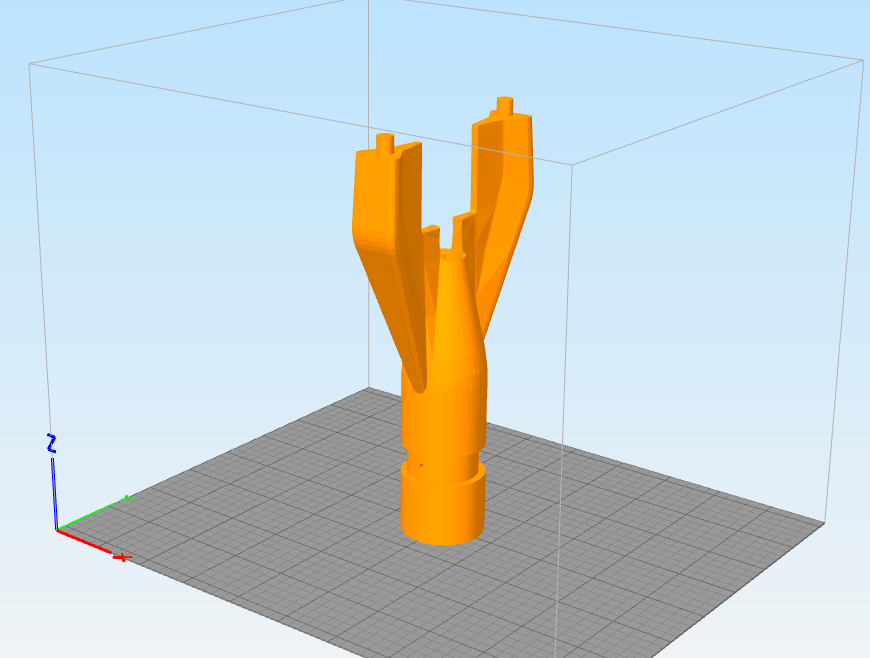

By the way, on a topic unrelated to your Mk2.5s but in line with VFAs, I've made all the parts necessary to try Prorifi's Phase-shifted Y axis belt drive! When I get done printing a lot of key tags, I might even put in on the printer!

¡no entiendo Español!

Nein! Nicht Versteh!

Я немного говорю по-руÑÑки но не очень хорошо, и...

I'm not very good at English either! Maybe someday I'll find a language I'm good at?

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

Thanks for the info.

I asked about the steppers since it is something that is talked about. I am skeptical on them being the issue though. Especially since the MK2 printed excellent before the upgrade.

Since the board and steppers didn't change, firmware was the only change there. I am wondering if there is an issue there?

I am looking at the extruder for issues since there apparently was an issue with the dual drive gears at one point in the past. Going to order new gears from Bondtech to replace them.

I'm just trying to narrow down what the issue might be since it was not there before the upgrade.

The issues I see are affecting the whole print and not just one axis

Here is a picture to show what I see. You can see how these vertical lines follow the contour of the hole and of the right edge of the part. This is not ringing or ghosting since the lines are all equal distance apart and span the whole side of the part. They are also on all four sides.

Thanks again for your thoughts on this.

RE:

That is some odd behavior.

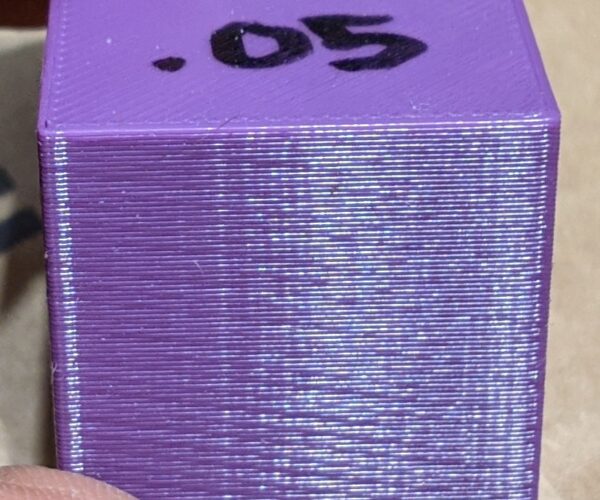

Are you printing in PLA with stock profiles? The surface finish looks kind of like what I get, and oddly it only does it with LA=0.05, which is built in to the stock profile. I found that changing to LA=0.04 or 0.06 made a dramatic change in the surface. You can just edit the gcode in a text editor if you want to try it.

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

I'm running a MK2.5s so I think I am on the older LA. I am on the latest Prusa firmware though.

Also using S3D.

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

If the evenly spaced marks are at 2mm intervals, this could be belt related as the tooth spacing is 2mm.

Just a thought..

¡no entiendo Español!

Nein! Nicht Versteh!

Я немного говорю по-руÑÑки но не очень хорошо, и...

I'm not very good at English either! Maybe someday I'll find a language I'm good at?

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

So have anyone tried the Prorifi3D stepper kit? I can see that it's a little pricey, but it is so easy and requires no tinkering - But does it work well?

RE:

I’m mildly interested too but, so far, I found no user opinions anywhere, or youtube videos from the usual reviewers.

Something I don’t like is that Prorifi3D web claims that the kits are in stock but, just a bit below in the same page, it says “current lead time 4 to 6 weeks before shipping”. In stock but up to 6 weeks for shipping?. That sounds rather fishy to me.

RE:

Providing some feedback, after one year on a Bear frame with Misumi LMU8 rods/bearing and OMC 0.9 Steppers (Machine #1), and just reassembled the original MK3S with Trinamic 049 Steppers and LM8UU bearings (Machine #2). Both frames are configured with BMG extruder and a Mosquito hot end, running 3.11.0 firmware.

While the 0.9 OMC steppers on the Bear frame (Machine #1) produce a bit smoother print, I am really liking the 1.8 degree Trinamic 049 steppers on the stock frame (Machine #2). I am using the standard firmware stepper settings, and the machine is very quiet and smooth. If not for the price premium, I'd think they would be the idle choice of motors from the factory.

The OMC's with linear correction set at +1.130 (Machine #1) produce a smooth finish with very fine, if any artifacts. I did have some 2mm X-Axis artifacts early on, which have been resolved with Bear X-Axis, a larger idler pulley and getting the belt tension loosened up a bit. Overall, I am very satisfied with how the machine performs, however acoustically it is louder, and with it being in my office I am inclined to dig into tuning a bit more, to see is there is a quieter happy spot.

Thank you Guy for leading the charge, VintagePC for input on Trinamic 049s and all that have contributed. I a finally content with how my machines perform.

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

Hello!

I am running a very modified MK3s with a bear frame, BMG, Mosquito hotend, and SliceHT, and other various upgrades. I am able to download and compile the firmware from Bondtech's GitHub here: https://github.com/BondtechAB/Bondtech-Prusa-Firmware/tree/Bondtech-MK3-FW3110

I now want to add 0.9 Moons stepper motors to my X & Y axis, as well as a LDO 0.9 pancake motor for my extruder. Does anyone know the changes to the code I would need to do? I am a little confused as there is different information scattered around. I've compared Git repos, code changes, and read a lot of responses but it seems a little overwhelming. Any help appreciated!

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

Okay, so I have taken the Bondtech 3.11 branch and merged in code from here: https://github.com/vertigo235/Prusa-Firmware/pull/15

and I will look to see if this is applicable: https://github.com/prusa3d/Prusa-Firmware/pull/2721/files

I am a Software Engineer so the implementation isn't terribly hard, it's just confusing because there is conflicting information out there so I have to weed through everything and do a lot of comparisons between files. My Moons motors should arrive next week, so I'll let you know how it goes!

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

Okay, I've installed the 0.9 Moons motors on X and Y but left the 1.8 Moons on my BMG extruder. I've modified one of the firmware variants with my changes and uploaded the firmware to my printer. Everything is working great so far on 3.11! The calibrations all passed and now I am doing the PID and heating calibrations before I move on to printing a test cube!

RE:

I installed them on my Prusa MINI and the difference is clearly visible, not even my Voron with 0.9 moons stepper can match the quality the MINI delivers now. I'll just wait for Prorifi3D to come out with more powerful motors and then buy them for my Voron right away.

Kann jemand, der sie getestet hat, bitte bestätigen, dass Prorifi3D-Schrittmotoren tatsächlich bei VFA helfen? Ich würde sie gerne kaufen, wenn sie wirklich funktionieren, aber ich habe noch niemanden aus der Community gesehen, der bewiesen hat, dass sie helfen.

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

Sir Isaac Newton is in charge here,

I loled.

If my post helps you please consider downloading & making one of my most popular Prusa-Printables 3D models below:1. Ultimate Printer Knob Upgrade - The Best Knob of Both Worlds 2. Prusa MK3S Right…

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

Hi, i am new to this forum. I am a material scientist with a focus on 3d printing and bought the MK3 when it came out. for me it seemed that the VFAs developed over time with wear on the stepper motors. Put the moon's on there and the difference is like night and day. I will post some pictures when I get home. I like the moon's because I am able to use LA for details which is awesome, but I was only able to put the old firmware from bunny science (really good manual) on there because I don't know how to reprogram the updated stock firmware myself, also just bought a bondtech lgx or how it's called which should be easy to include with this firmware. I find the moon's super quiet in stealth mode and also quieter in normal than the stock motors. At 0.12mm layer height, 50mm/s they run hot in stealth mode at least now during summertime, so I bought a little 5W fan which is enough cooling + metal sinks on all drivers. They don't have a lot of torque so going faster in stealth was not possible. For now I am really really happy with the upgrade, so I want to thank everybody in this thread for the effort. I read that lately @Gabe and @HBprint were able to run the new firmware with 0.9 stepper, so I would appreciate it alot if you could share your firmware or maybe have a link for a good tutorial... I am interested because the updated firmware versions include a better version of LA and a possibility add a superPINDA. With all the help and user reviews I am top motivated to repuild the x y and z axis now to lower ringing and layer displacements 😉

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

Hey @Mosephus, I can definitely help you as I went through this process. I should just publish my code changes in my own branch but it's a little disorganized as I simply edited the variant that I needed. Do you see any variants that match your printer here, or are you running stock hardware besides the 0.9 motors?

https://github.com/BondtechAB/Bondtech-Prusa-Firmware/tree/Bondtech-MK3-FW3110/Firmware/variants

I will probably take the time and create a branch and just delete the variants that are not updated and add mine + yours. Then if you agree with the changes, I can build it for you and give you the hex file. Let me get to this and verify the changes! In the meantime, please tell me your setup. One more thing, are which motor are you using?

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

Okay, here are my changes in my fork:

you can compare it with what I copied:

If you want to make your own variant you will have to grab the original Bondtech variant file and compare it with changes that I've added for 0.9 motors, while retaining settings that make sense for your hardware. For instance for me I have an LGX extruder so I changed TMC2130_USTEPS_Z to 16 and DEFAULT_AXIS_STEPS_PER_UNIT to {100,100,3200/8,400}. Let me know if you need help or want me to add a variant file for you based on the hardware you have.