RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

I think those values put it rather close for the skelestruder. Based on my experience, I suspect an extra 3 mm might cause it to unload occasionally.

Based on the E3d tech doc ( https://e3d-online.dozuki.com/Document/WKUGPLmiMEGdwuCD/PRUSA-BREAK-175-%28Edition-1%29.pdf )

the distance doesn't really check if it makes it past the step in the PR heatbreak, so I suspect the main goal is to ensure you get the filament head past the two main jam points: the top of the PTFE and into the metal part of the hotend without issue. So it would stand to reason that any value that loads more than the distance to the end of the PTFE, and unloads just enough (e.g. 1-2mm more than the same end-of-PTFE distance) to determine whether the filament jammed at that changeover is sufficient.

Loading too much may cause other problems, if you start dipping into the melt zone you can pick up molten plastic and start forming strands and junk that will cause you grief later - I'd see the previous colour stuck to the tip on load fail when my IR sensor wasn't quite setup right and my unload retraction speed was too high, causing filament to get sucked further up than it should have been.

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

Prusa clearly has move distances in MK3S can_load that puts the filament into the melt zone. Should we "correct" their software and parallel fix the other extruders? I would expect them to know what they are doing. On the other hand, it is a Prusa MMU2S.

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

If it ain't broke... I'd leave it alone for the sake of future compatibility/merges/changes/unintended consequences. Though perhaps it is worth actually seeing if we can get an answer from someone at PR as to the intent of that behavior rather than speculation- it's fairly new and did not exist prior to the 3S variant (or at least, I cannot find reference to it in mmu.cpp in early May; it may have been renamed and relocated)

As soon as you run into the melt zone you also risk extruding a blob... :-/

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

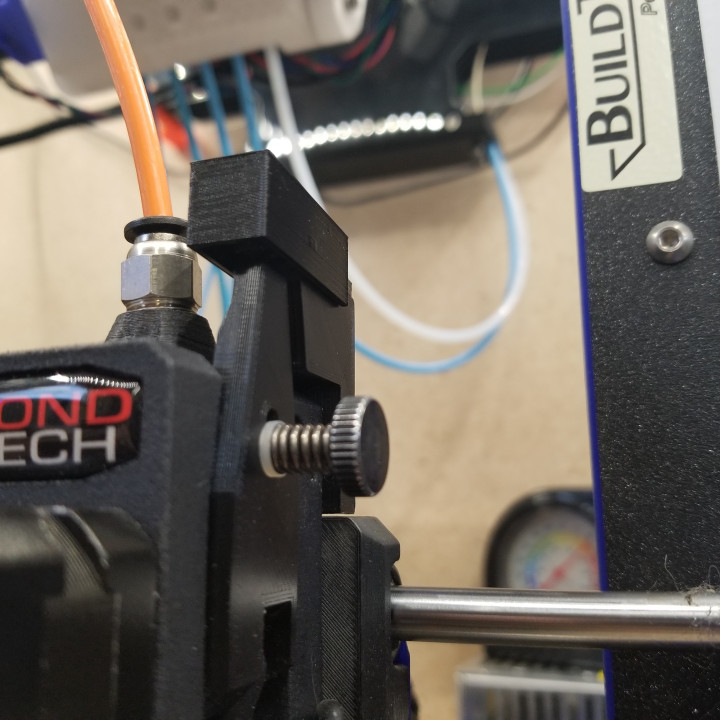

I am not sure if they have the CAD files you need here, but this is where Bondtech keeps them. The MK3s Sensor Add-On folder is the method they used to make the new style sensor work with the old style Extruder Assembly (the one with the sensor sideways instead of flat). With the new style (sensor is laid flat), it is setup the same way Prusa sets theirs up.

https://github.com/BondtechAB/Bondtech_Prusa_i3/tree/master/CAD-Files

And if it helps, here is the installation manual:

https://support.bondtech.se/Guide/13.+Prusa+i3+MK2.5S+-+MK3S+Upgrade+Kit+-+Installation/43?lang=en

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

Prusa clearly has move distances in MK3S can_load that puts the filament into the melt zone. Should we "correct" their software and parallel fix the other extruders? I would expect them to know what they are doing. On the other hand, it is a Prusa MMU2S.

If you want to do a test, I am game to run anything.

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

Ugh! Getting a headache trying to figure out Prusa's state machine that implements the MMU2S actions. Still trying to find where it does the load to Bondtech sensor.

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

Ugh! Getting a headache trying to figure out Prusa's state machine that implements the MMU2S actions. Still trying to find where it does the load to Bondtech sensor.

Are you looking in the MM-control-01 repo? Anything where the extruder gears are not engaged with the filament is handled there as part of the T# gcode (filament retrieve, selector/idler move, load-to-sensor)

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

Just reading through mmu.cpp in the firmware.

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

Yeah, you won't find it there. The Einsy does a handoff of control to the MMU during a T code and then just waits for it to acknowledge it's done before resuming. Extra load distance beyond the sensor will require modifying the MMU firmware.

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

Gotcha. Explains why I can't find it. No really wanting to take on maintaining a branch of MMU firmware.

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

Yeah - as noted the only option if no IR door is available is to revert to Mk3 firmware and calibrate your bowden length.

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

Yeah - as noted the only option if no IR door is available is to revert to Mk3 firmware and calibrate your bowden length.

I can do that. I wonder if I can find the distance in the MMU firmware. I will look, but this will be my fallback when I fail to find it. 🙂

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

umm during a filament change the MMU starts feeding till it gets back the "A" from the EINSY when the IR sensor sees filament, then the MMUS disengages and the EINSY takes over and does the rest of the load and purge. I need to double check but I think the only time both bondtechs are engaged at the same time is as the filament is reaching the extruder bondtech till the IR sensor triggers

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

Unfortunately, that still doesn't help if the extruder lacks a Bondtech gear position based sensor. The MMU2S stops upon detection at the sensor above the Bondtechs resulting in Cybersage's problem. We have established that will take either a new sensor arrangement, modifying the MMU firmware, or using the MK3 version.

Meanwhile, this led me to look more into mmu.cpp and what different extruders distances may be issues in

static bool can_load()

void mmu_load_to_nozzle()

Both of those perform moves that depend on distance height of extruder. I have made adjustments to both to account for Skelestruder, Bondtech MK3S, and Slice Magnum (in BNBSX or MK3).

can_load() I kept the tip definitely out of the melt zone and end up with tip 8 mm below Bondtechs for all the extruders.

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

Oh. It dawned on me that can_load actually HAS to push to reach the tightest spot in the path. That why they push it so far. Basically push tip to jam (if it has a big knob). If it jams, the subsequent pull back puts tip closer to Bondtechs. The subsequent testing is via incrementally pulling filament back a distance and seeing if Bondtechs lose grip. Hence pull back should always be be to 8 mm below Bondtech.

Distances in can_load updated once more

1st move is to melt zone. Yes, that is what Prusa intended and we're going to leave it that way. It's the position at which the tip will encounter max resistance.

2nd move tries to bring tip back to 8 mm below Bondtechs. If it slipped due to a jam, the tip ends up less than 8mm below Bondtechs. Testing phase will then lose grip of the filament.

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

Does the current firmware tou have do this, or do you need to make changes?

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

The above changes to can_load() and mmu_load_to_nozzle() are already in my repository.

Sorry, it doesn't help with your issue. I'm examining the Bondtech lever door to see if one can fit a chimney adapter to it.

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

There are some, they were used prior to the new design. The door lever gets a flag on it and the sensor sits above the flag.

https://www.myminifactory.com/object/3d-print-prusa-mk3s-mmu2s-ir-sensor-mount-bondtech-bmg-89362

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

I think that chimney mod is what you will need if you want the MMU2S to play nice with the Bondtech MK3S Extruder.

There is one other thing that might be a problem for MMU2S. Bondtech CAD drawings show the filament path above and below the drive gears are molded as part of the extruder plastic. That let them go tight around the drive gears and intrude into the filament groove. That's good for flex filament. However, the CAD bore for the filament path is 2.0 mm. If you get a bigger than 2.0 mm filament tip, the molded filament path above and below the Bondtech drive gears looks awfully tight.

What is good for flex filament is almost exactly the opposite of what is needed for MMU2S loading.

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

Skipping steps during printing is almost always indication of a mechanical issue with an axis, not the motor itself. The 0.9 have a bit less torque and that can cause a marginally acceptable axis to show up as a problem.

1. Is this a belt skipping a whole tooth? If yes, belt is too loose.

2. Is this pulley loose on motor shaft? Check that both set screws are correct. One must be perpendicular to motor shaft's flat. Does the motor lack a flat? Grind a flat.

3. Is this a layer shift in the midst of a print? Check that rods and bearings are completely free running and correctly lubricated.

Hi I triple checked everything but now i think i've resolved my issues by playing with PWM Grad Y value for the skipping steps and The stallguard setting for the LDO not homing properly.

Now I will do some test and keep the best motor

Wich current do you recommend for the OMC motor ? And for the LDO ?

Thanks again for your work with the VFA issue.