RE: QuickChange mod for i3 MK3/S/+ printhead?

Anyhow, getting down to brass tacks: some kind of go-between connector, perhaps similar to:

https://www.amazon.com/UTEBIT-Release-Compatible-Manfrotto-200PL-14/dp/B07VVP7HSK/ref=pd_di_sccai_2?pd_rd_w=TUqED&pf_rd_p=c9443270-b914-4430-a90b-72e3e7e784e0&pf_rd_r=M8ENS58SD3V14H9KB7WF&pd_rd_r=53abddc6-2121-40d1-b9db-e982e84f9bc7&pd_rd_wg=xQJi4&pd_rd_i=B07VVP7HSK&psc=1, would allow quick and easy mounting/demounting of the printhead, and some kind of spring-pin connection, like that used by the kickstarter or like:

to make/break the wired connections during mount/dismount would probably do the business.

You'd only need one quick-connect mechanical mount, and then from there you could print as many matching plates are you want:

https://www.thingiverse.com/thing:1347792

None of these parts are inherently expensive.

RE: QuickChange mod for i3 MK3/S/+ printhead?

@dimprov

Where did you find that sprint loaded connector Dimprov?

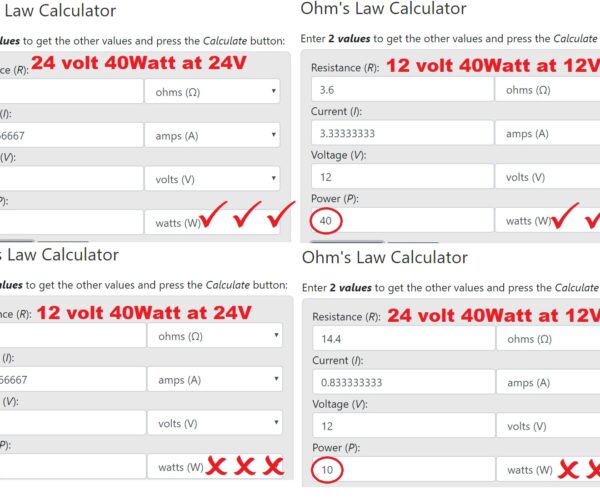

do you know what the rated current is for the individual contacts? from the table below, the heater contacts need to be able to carry in excess of 3.5 amps for the Mk3/ Mk3s/Mk3S+ with the 24 volt - 40 watt heater,

and in excess of 7 amps for the Mk2/ Mk2S/ Mk2.5/ Mk2.5S and any predecessors with the 12 volt power supply and 40 watt heater,

If you have a higher wattage heater, the heater contacts will have to be suitably uprated...

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: QuickChange mod for i3 MK3/S/+ printhead?

@dimprov

Where did you find that sprint loaded connector Dimprov?

do you know what the rated current is for the individual contacts? from the table below, the heater contacts need to be able to carry in excess of 3.5 amps for the Mk3/ Mk3s/Mk3S+ with the 24 volt - 40 watt heater,

and in excess of 7 amps for the Mk2/ Mk2S/ Mk2.5/ Mk2.5S and any predecessors with the 12 volt power supply and 40 watt heater,If you have a higher wattage heater, the heater contacts will have to be suitably uprated...

Regards Joan

I just typed "spring pin connector" into google images, which pulled up a gazillion possibilities, of which I just picked one as a placeholder, which is the image that I posted. I don't know what its current rating is. One could do a more serious parametric search on digikey or mouser to find something with a datasheet that would guarantee sufficient ampacity.

RE: QuickChange mod for i3 MK3/S/+ printhead?

For a proof of concept, I think one could forgoe the camera mount and just have two plastic 3D printed interface plates that bolt together (ideally with a spring-pin connector between them, but alternately just with whatever plug-sockets you have on hand). The back plate would bolt to the Prusa carriage by whatever bolting arrangement it currently uses, and the front-plate would bolt to the Prusa printhead, by whatever bolting arrangement it currently uses. Then bolt those two plates together along a flange of some kind, and voilà,, you have a way to attach/detach using just bolts along the flange. From that point on, no further assembly/disassembly required, except for the bolts along the flange.

RE: QuickChange mod for i3 MK3/S/+ printhead?

@dimprov

I would prefer doing away with the 'bolt together' aspect and go with magnets. Click and place. Place and click.

It would be cooler, and less involved work.

RE: QuickChange mod for i3 MK3/S/+ printhead?

[...] I would prefer doing away with the 'bolt together' aspect and go with magnets. Click and place. Place and click.

Curious if somebody has done an analysis of print finish using the magnet approach. I'm curious about vibration effects and what size of magnets are needed to ensure they're not a problem.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: QuickChange mod for i3 MK3/S/+ printhead?

[...] I would prefer doing away with the 'bolt together' aspect and go with magnets. Click and place. Place and click.

Curious if somebody has done an analysis of print finish using the magnet approach. I'm curious about vibration effects and what size of magnets are needed to ensure they're not a problem.

I wonder about that too, but if the PitStop works, then Bill Marcy's wish should be equally possible. I think PitStop uses just 6 in total, with 3 on each side, and they're fairly small diameter. So, that would be a rough ballpark for how many would be needed. IIRC, n52 strength is the strongest you can buy without a nasty pinch hazard? I have some 1 inch diameter n52's, and they're damn hard to separate.

RE: QuickChange mod for i3 MK3/S/+ printhead?

[...] I would prefer doing away with the 'bolt together' aspect and go with magnets. Click and place. Place and click.

Curious if somebody has done an analysis of print finish using the magnet approach. I'm curious about vibration effects and what size of magnets are needed to ensure they're not a problem.

I wonder about that too, but if the PitStop works, then Bill Marcy's wish should be equally possible. I think PitStop uses just 6 in total, with 3 on each side, and they're fairly small diameter. So, that would be a rough ballpark for how many would be needed. IIRC, n52 strength is the strongest you can buy without a nasty pinch hazard? I have some 1 inch diameter n52's, and they're damn hard to separate.

I am unsure of hte weight penalty (But I am sure there woudl be a significant one), but an electromagnet, or a few electromagnets, keeping the tool head on the mounting plate, and with a flip of a switch, releasing it. That's pretty sexy.

RE: QuickChange mod for i3 MK3/S/+ printhead?

[...] I would prefer doing away with the 'bolt together' aspect and go with magnets. Click and place. Place and click.

Curious if somebody has done an analysis of print finish using the magnet approach. I'm curious about vibration effects and what size of magnets are needed to ensure they're not a problem.

I wonder about that too, but if the PitStop works, then Bill Marcy's wish should be equally possible. I think PitStop uses just 6 in total, with 3 on each side, and they're fairly small diameter. So, that would be a rough ballpark for how many would be needed. IIRC, n52 strength is the strongest you can buy without a nasty pinch hazard? I have some 1 inch diameter n52's, and they're damn hard to separate.

I am unsure of hte weight penalty (But I am sure there woudl be a significant one), but an electromagnet, or a few electromagnets, keeping the tool head on the mounting plate, and with a flip of a switch, releasing it. That's pretty sexy.

I've heard of feature creep, but this is more like feature sprint! 😀 What's next? "Alexa, demount the printhead."

I like your thinking though. 😎

RE: QuickChange mod for i3 MK3/S/+ printhead?

@dimprov

If you are going to engineer something, might as well over engineer it.

RE: QuickChange mod for i3 MK3/S/+ printhead?

@dimprov

If you are going to engineer something, might as well over engineer it.

RE: QuickChange mod for i3 MK3/S/+ printhead?

I guess it really is a thing, because they've already received a product review!

Also, pledges have jumped considerably today as compared to yesterday.

RE: QuickChange mod for i3 MK3/S/+ printhead?

[...] I would prefer doing away with the 'bolt together' aspect and go with magnets. Click and place. Place and click.

Curious if somebody has done an analysis of print finish using the magnet approach. I'm curious about vibration effects and what size of magnets are needed to ensure they're not a problem.

Alternatively, what would be a conservative number for the number of pounds of holding force required to hold the printhead rock steady? If we had that as a target, then we might be able to back out from there the number and size of n52 magnets needed to do the job. For instance, here they're promising 33 pounds of clamping force, I'm guessing per pair of magnets:

https://www.amazon.com/DIYMAG-Powerful-Neodymium-Rare-Earth-Incredibly/dp/B08CZGV3Z8?th=1

So, buy 6 for $11 and you'd have 99 pounds clamping force. More than enough overkill? What's the usual criteria for deciding this sort of thing? From what little I know about free body diagrams, I'm guessing it only needs to exceed worst-case acceleration/deceleration/jerk forces. Maybe someone reading this knows and can comment?

As the saying goes, a good engineer can do for a nickle what any damn fool can do for a dollar.

RE: QuickChange mod for i3 MK3/S/+ printhead?

OK, I'll take a stab at it. I don't know what the specs are on the prusa x-axis stepper, but looking at Nema 17's on amazon and comparing to the Prusa steppers, it looks as though the Prusa's are probably less than 85ounce-in of torque. 85 ounces is about 5.3 pounds. The idler radius is, say, about 1/2 an inch. That means maximum torque might be around 10.6 pounds, but we'll round that to 11 pounds. So, according to that back of the envelope calculation, we'd need only about 11 pounds of clamping force. Right? So, anything more than 11 pounds total clamping force for the magnets should be plenty. Also, if more than that, then separating the magnetically coupled printhead by hand from the baseplate might (?) start to be hard.

RE: QuickChange mod for i3 MK3/S/+ printhead?

Ooops, I conflated in-pounds torque with pounds clamping force there, which is probably an error. Not sure how to make that conversion. Anyone feel free to offer up a better calculation.

RE: QuickChange mod for i3 MK3/S/+ printhead?

Aha. So, looking at the Teaching Tech review video, the xchange magnet can hold at least 4kg of weight, so consider that as yet another datapoint.

It did also mention that an xchange setup for the Prusa is "already in the works," though who knows how long that may take, if ever. I do think the Prusa market is probably a better fit for them, since with an Ender 3 platform already being inexpensive, you could maybe justify just buying another Ender 3 instead of an xchange kit, since having an extra Ender 3 would also multiply your print capacity as well as provide fallback redundancy. Hmm... I think I may be talking myself into an Ender 3 here. 😀

RE: QuickChange mod for i3 MK3/S/+ printhead?

@dimprov

Started on an Ender and I Still wake up at night sweaty with fear over those damned leveling wheels. Buy another Prusa, sleep soundly.

RE: QuickChange mod for i3 MK3/S/+ printhead?

Yeah, I suspect the baseline stock Ender 3 wouldn't be much fun, what with all the noise it generates, and above that the xchange value proposition becomes more compelling. Besides, it's hard to take seriously a printer whose build plate is attached with paper clips. 😏

I'll try importing the Prusa MK3S printhead parts into fusion360. If I can easily project their bolt-hole locations onto a sketch plane, then I'll make the interface parts (with flange) that I described above and give that a whirl.

RE: QuickChange mod for i3 MK3/S/+ printhead?

Closing the loop: I ended up ordering a corexy printer today because after careful consideration I see no way around a minimum of 350mmx350mm build area for some current projects. This purchase is not a knock against Prusa printers, though: unless I overlooked something, all of the Prusa models have print areas that are simply too small with respect to my projects' minimum size requirements.

I'm pretty sure the corexy will have an easier printhead to swap, so rather than go down a possible rabbit hole to build an adapter from scratch or waiting for PrinterMods to make a custom xchange for Prusa, I'll likely deem the corexy as my "go to" printer for swapping printheads. Time will tell.

RE: QuickChange mod for i3 MK3/S/+ printhead?

A most interesting thread.

Thanks for posting all the links and ideas.

Hope for some feedback posting from people that will implement these mods.

Cheers and stay safe.

REPAIR, RENEW, REUSE, RECYCLE, REBUILD, REDUCE, RECOVER, REPURPOSE, RESTORE