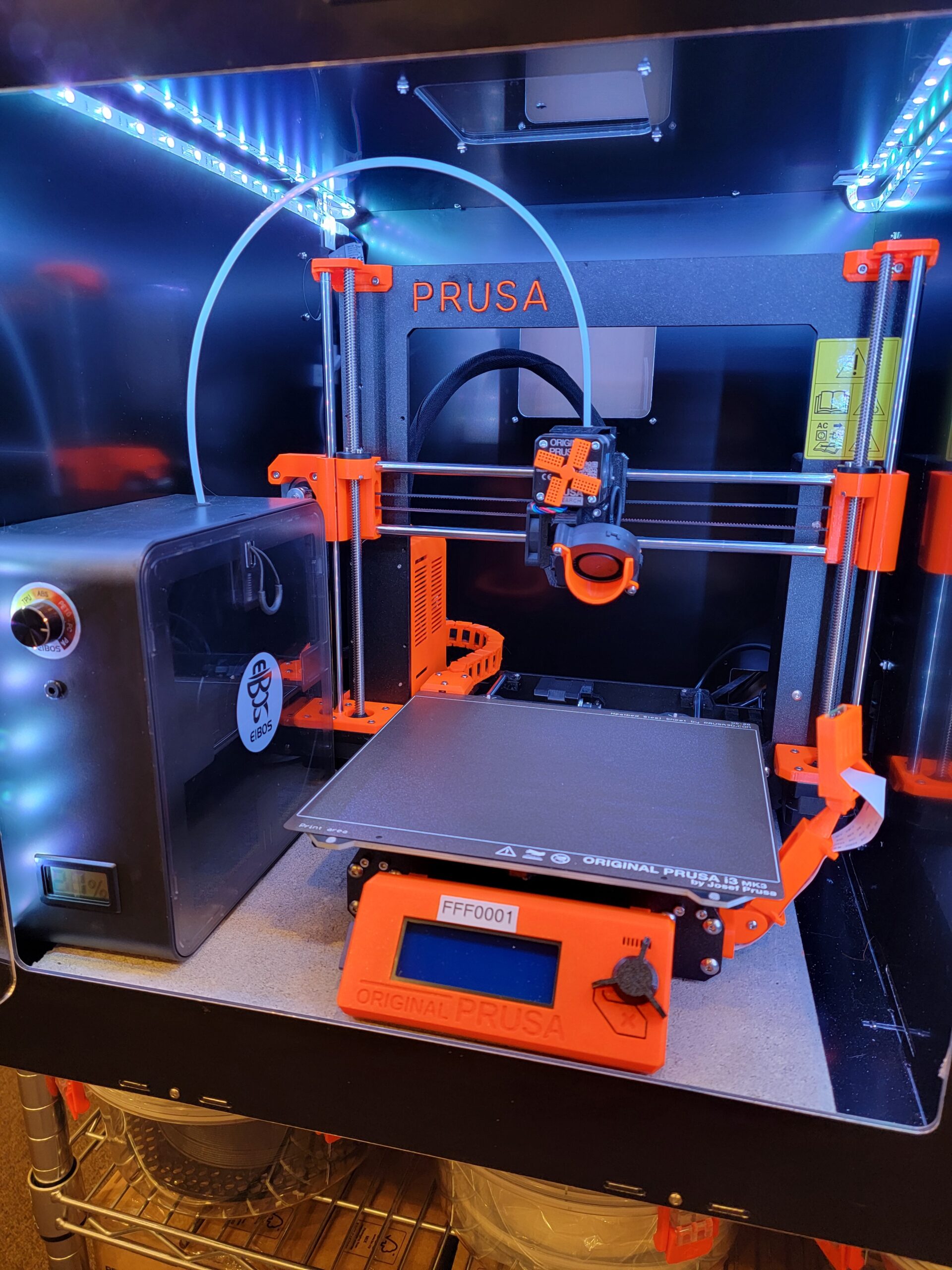

MK3S+ Based Printer Farm - 1 Production Unit

Here is a single production unit of my printer farm. As I scale, I build one of these rack setups at a time. My business model has my printing 95% Polycarbonate products (with a small amount of that being carbon fiber reinforced). So I required enclosures with filament dryers that go to 70*C.

Each printer setup has:

- a Prusa i3 MK3S+ with all polycarbonate printed parts

- bed cables are in a cable chain going to redesigned pdu case/octopi case

- an enclosure with lighting, air handling, and a humidity/*C thermometer

- a filament dryer that goes to 70*C

- a Raspberry PI 4b (OctoPrint) with customer case integrated to PDU case hard wired for network

- a Raspberry PI Cam v2 with extended cable fixed to the right side.

- 1500VA UPS with AVR (automatic voltage regulation to provide clean power)

To manage the farm I use OctoFarm running on a Raspberry Pi 8GB with 128GB sd and 1TB SSD attached for data capture and analysis.

I have a separate cleanup and finishing table from my printer maintenance table, each setup with all the tools, consumables, and parts needed for that station.

I monitor fire/smoke/co/etc with a wifi detector and monitor the VOC's, humidity, and other bad stuff with AirThings Wave Plus, and purify the air with the Austin Air Healthmate Plus.

The rack is a Heavy Duty chrome setup with the perfect amount of space for 2 printers and a UPS/AVR per row X 3 rows, plus 2 rows at the bottom for filament storage.

My 2 secret weapons that actually took the bulk of my time to perfect was the annealing system and tumbler. For annealing the parts, I had to dial in the right temp/time duration combined with cool down time. This formula slightly changes depending on the size of the parts. The tumbling process evolved greatly, started with crappy Harbor freight sized tumblers, ended up with Industrial sized 400 pound beast of a tumbler, but the results are fantastic. The Polycarbonate tumbles really nicely. Besides running the prints in a temperature stabilized enclosure (usually around 50*C), the annealing and tumble process put the finished touches on the end result. Dang near injection molded looking and performing, but all of the agile and speed advantages of additive manufacturing.

I have 2 of these production units now, for a current capacity of 12 printers, but estimate, I will double before the end of the year. Other than possibly adding a heater to the enclosure to go from 50*C to about 70*C, I think I pretty much have this where I want it now. I'm in the middle of building my building to house the farm, a 40'x60' metal building on my property. I'm hoping to be moved into it by summer and hope to be ready to scale into the third production unit. I toyed with building a farm from clones and even mini's, but decided to go the MK3S+ route. More money up front, but I want as close to 99% efficiency as possible, and at $60/KG, I wanted to reduce wasting this PC filament as much as possible.

RE: MK3S+ Based Printer Farm - 1 Production Unit

Not sure why my phone camera skewed the tops of the upper most printer enclosures. They are nice and straight in real life, lol.

RE: MK3S+ Based Printer Farm - 1 Production Unit

I decided to go with a Gigabit network switch for all of my OctoPrint servers and my OctoFarm server. WIFI was working, but I plan on growing this into triple digits in a couple years, so made the decision to go wired. This also should allow for cleaner video feed consumption and data gathering from the OctoFarm server. My WIFI network is already in need of a campus setup and I didn't want to tackle upgrading that right now.

Any one else decide to build their farm with OctoPrint, OctoFarm, and wired instead of wireless?

RE: MK3S+ Based Printer Farm - 1 Production Unit

Neat and clean. Very pretty!

Do you have a link to the rack/enclosures you're using?

Octoprint/farm setup: I'm a bit surprised you see a need to go wired. Okay, I do have my Pi's connected to a gigabit switch as well but I did it because I could, not because I needed to. A good wifi network should easily handle the traffic. I have about 80 devices on a Plume mesh network and have never experienced a bottleneck.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: MK3S+ Based Printer Farm - 1 Production Unit

Neat and clean. Very pretty!

Do you have a link to the rack/enclosures you're using?

Octoprint/farm setup: I'm a bit surprised you see a need to go wired. Okay, I do have my Pi's connected to a gigabit switch as well but I did it because I could, not because I needed to. A good wifi network should easily handle the traffic. I have about 80 devices on a Plume mesh network and have never experienced a bottleneck.

My current wifi network has over 150 devices on it. I wanted a clean pipe for the farm now so as I grow ot to larger numbers the only traffic on that network is the farm.

I also have a lot pf other 2.4 and 5 ghz devices that from time to time give me problems. At least now the pipe I have is essentially a "closed circuit".

Any way, I do use wifi networks, mesh networks, campus networks in my day job, I just didn't feel like cleaning up my current wireless mess, and instead focus on building out this farm with a design I can easily scale without any contentions or residue from my current overloaded wireless networks.

RE: MK3S+ Based Printer Farm - 1 Production Unit

Neat and clean. Very pretty!

Do you have a link to the rack/enclosures you're using?

Octoprint/farm setup: I'm a bit surprised you see a need to go wired. Okay, I do have my Pi's connected to a gigabit switch as well but I did it because I could, not because I needed to. A good wifi network should easily handle the traffic. I have about 80 devices on a Plume mesh network and have never experienced a bottleneck.

I just use the enclosures from PrintedSolid for the Prusa style printers.

I got most of mine during the black Friday sale at $165 each with no shipping and handling.

RE: MK3S+ Based Printer Farm - 1 Production Unit

Looks cool 👍

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: MK3S+ Based Printer Farm - 1 Production Unit

I decided to go with a Gigabit network switch for all of my OctoPrint servers and my OctoFarm server. WIFI was working, but I plan on growing this into triple digits in a couple years, so made the decision to go wired. This also should allow for cleaner video feed consumption and data gathering from the OctoFarm server. My WIFI network is already in need of a campus setup and I didn't want to tackle upgrading that right now.

Any one else decide to build their farm with OctoPrint, OctoFarm, and wired instead of wireless?

I find having devices connected directly provides the best connection

RE: MK3S+ Based Printer Farm - 1 Production Unit

@HangsF4Fun

Thanks for sharing all this information and experience! Really interesting to read how you're taking this printer which is accessible for hobby-makers, and using it in such a professional setup.

If it's okay by you I would like to ask a couple more questions.

- You mentioned you use a tumbler, but I found this post of someone who tried it out and said it doesn't work, it sounds like you might need to right tumbler material to get the best results. Which material would you recommend?

https://kiltedcraftworks.com/2017/08/30/tumbler-sanding/

- You are being really professional about drying out your filament, having high temperature enclosures and lots of customizations on your printers, cool stuff! How much of this is needed to print with PC? Does it simply reduce print failures, or also increase quality? Is there anything you've done which afterwards you found wasn't worth the time investment?

- Prusament PC Blend Carbon Black has been sold out for as long as I can remember, has this been a strain on your business? Have you found it difficult to find alternative, reliable suppliers?

If you've made it this far, then thanks a lot for reading through! I think it's really cool of you that you've shared your experiences on this forum