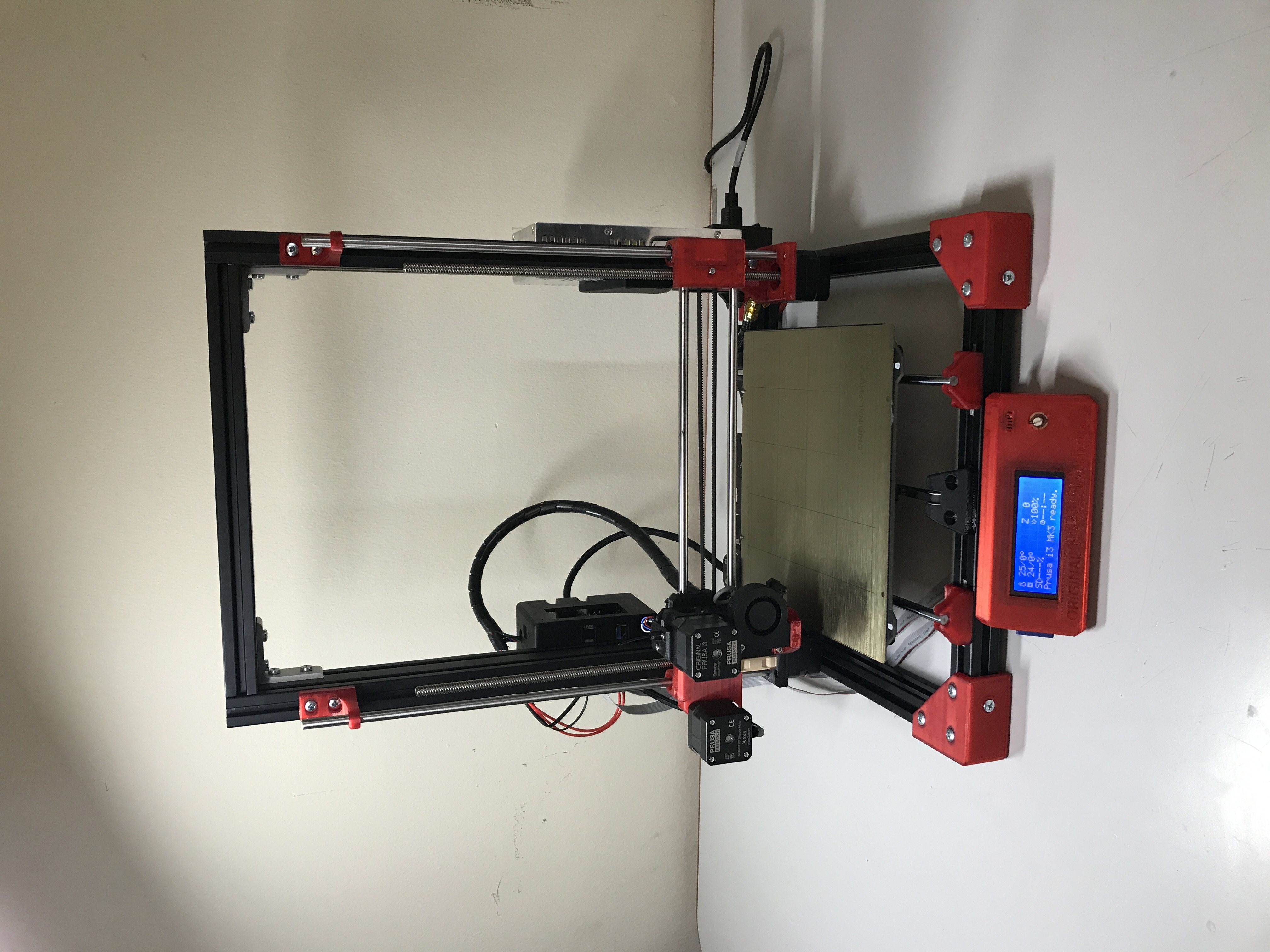

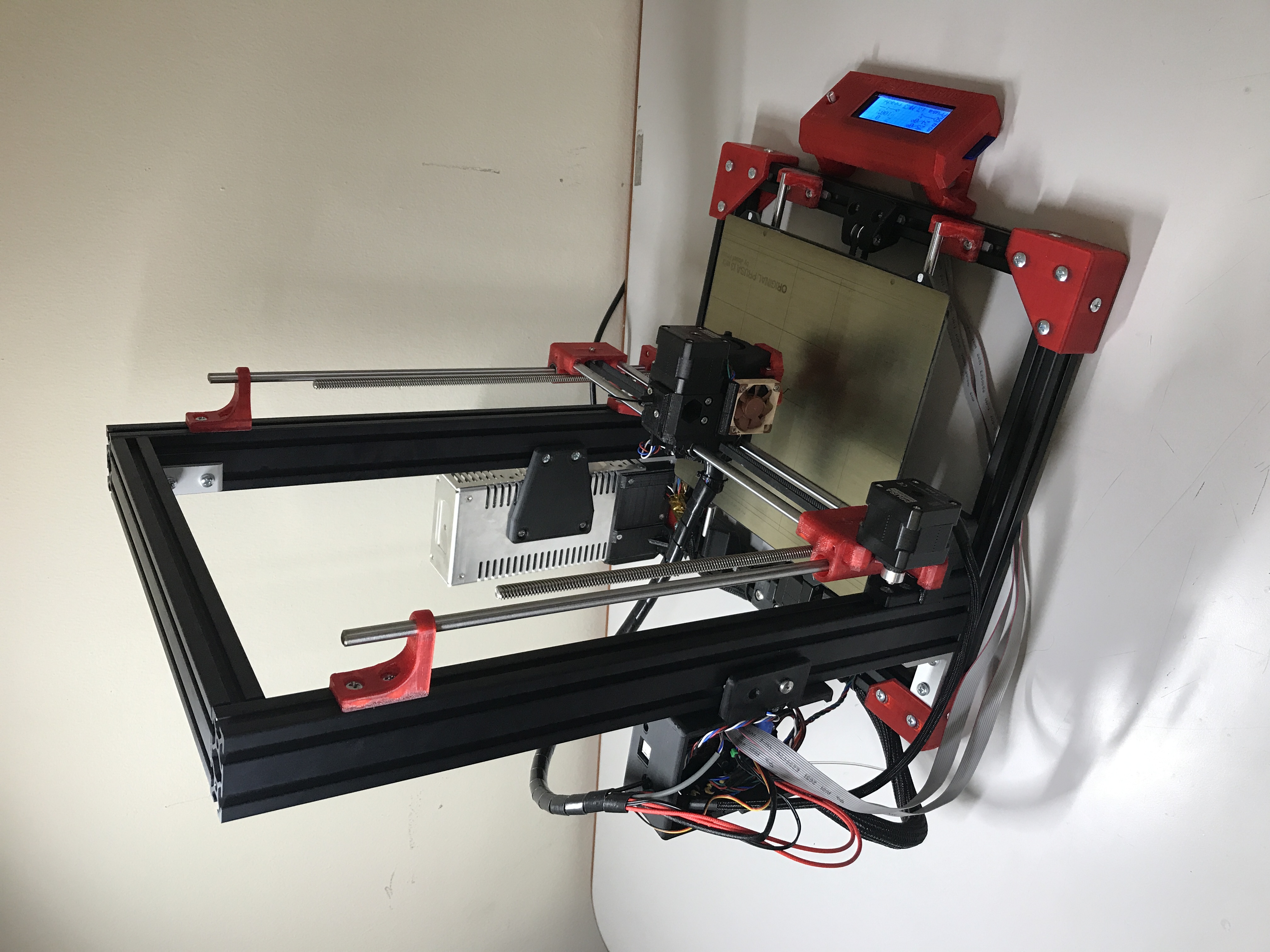

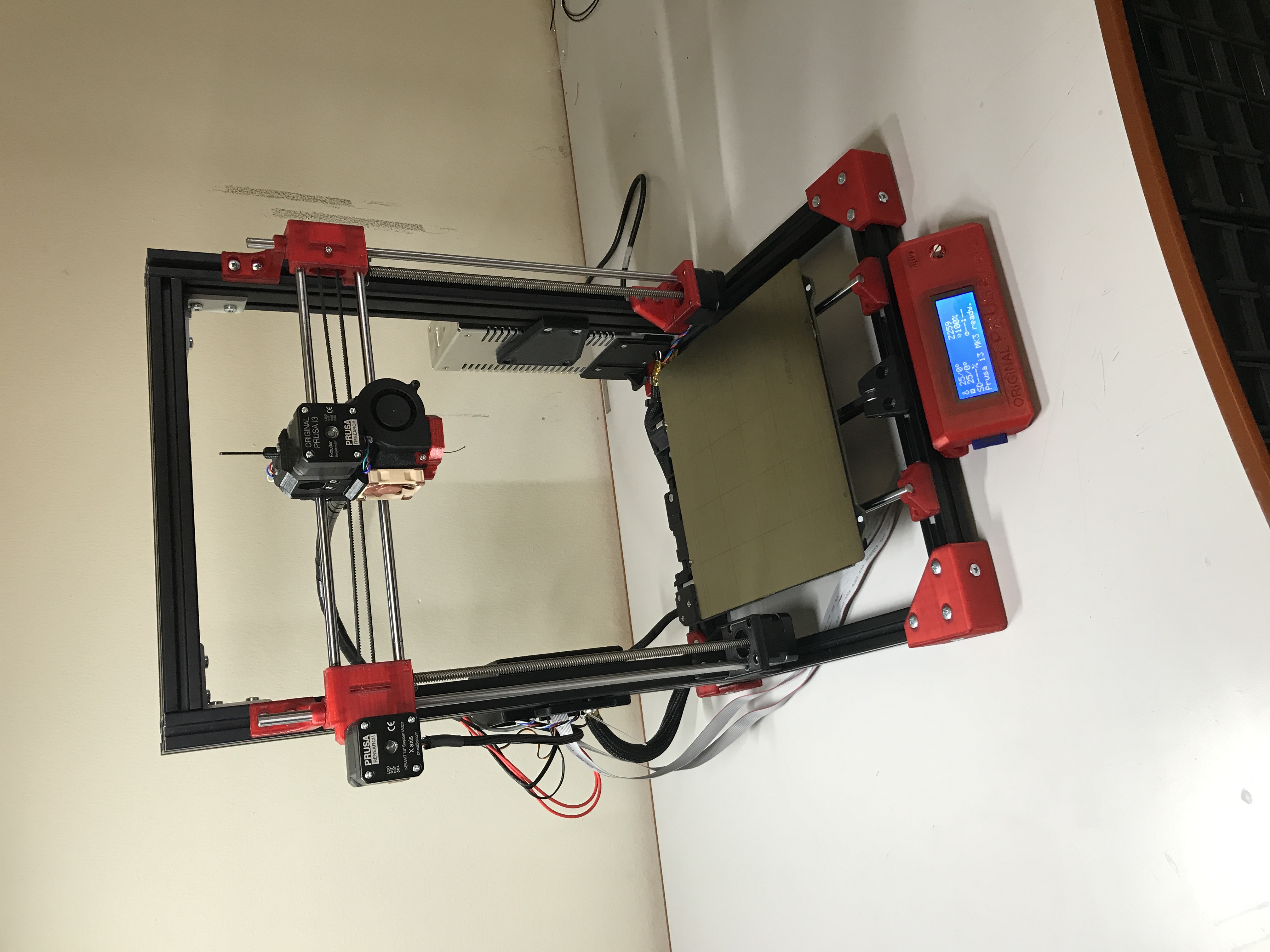

MK3+, Z Axis Rework

As much as I love my MK3, 8 inches of build height is simply not enough for my uses. The stock MK2/3 uses 12" lead screws but cuts out 4" of that build volume due to the frame size and improper X arms. I designed a new frame for my MK3 and assembled the X axis upside down, so the POM nuts rest at the bottom of the assembly, giving them access to the entire screw. This is actually a pretty simple modification and when paired with longer Z axis shafts, gives a build volume of just over 11" out of the stock motors. The total cost of the new frame, Z rods are required hardware was only ~$120.

Re: MK3+, Z Axis Rework

Very nice work !

Wer freundlich fragt bekommt auch eine freundliche Antwort.

nec aspera terrent

Re: MK3+, Z Axis Rework

Great conversion! How about posting some print quality pictures? I like the vertical extrusion setup. It looks like it could be more rigid by not having a split frame.

MK3 Kit, Designed, built 4x4 CNC Plasma Cutting Table, Motorcycles Bigdogbro's Adventures

http://www.youtube.com/channel/UC5djrxBeeOKB9_6rHnn6G8A

Re: MK3+, Z Axis Rework

NIce work! How are you keeping the Z axis perpendicular to the XY frame? I didn't see any gussets.

Re: MK3+, Z Axis Rework

Thanks for your interest 🙂

The build is all finished now, and I've got some decent pictures of it that should explain how everything lines up. It's a very simple frame, the bottom 4 extrusions are just held together with the printed corner brackets and screws. The Z axis extrusions bolt into the frame using 90* aluminum brackets, keeping everything straight and rigid. The 2550 extrusions ensure a straight and perpendicular frame in tandem. It uses about 80 tnuts and M5 screws, plus a few more self tapping screws for the electronics enclosures.

I've done a conversion for my Mk2s as well, it's now a full Mk3 setup with a Mk42 bed and an additional power supply and mofset. I've uploaded all the new brackets for both machines to the thingiverse page.