Issue after nozzle change.

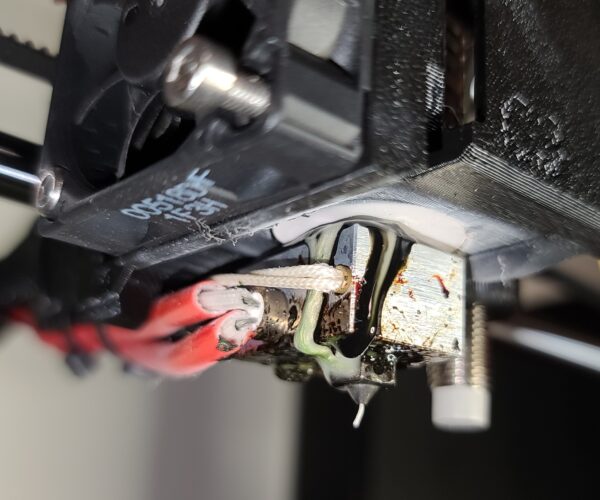

I recently changed from the stock nozzle to an E3D Nozzle X 0.4mm and though I had installed it correctly, following the post on the website. However, as you can see in the picture, I have some leakage. The stock nozzle Z setting was -1.163mm, the new nozzle is -0.770mm. I stopped turning the nozzle when I thought I bottomed out. So, did I break my hotend heatbreak, or did I just not seat the nozzle far enough? Can this be salvaged? I did get about 24hours of printing in before it got to this state. I don't know if you can tell it, but there are 3 colors there.

RE: Issue after nozzle change.

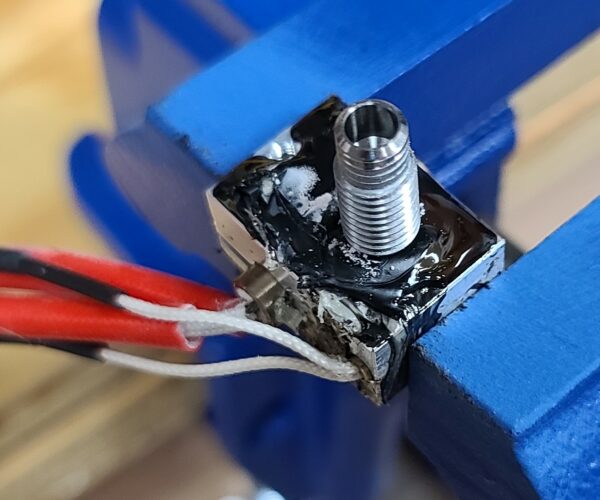

Hello. Do you have a gap betwwen the nozzle and the hotend ? of course by tightening well.

Because if not inside the hotend the gap is really there and here (inside) there is a leak.

Look at the assembly manual.

And did you do all the manipulation at the good temperature (280°C) ?

RE: Issue after nozzle change.

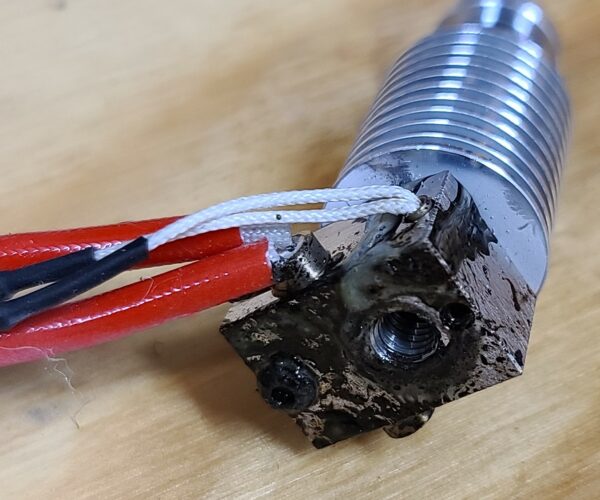

There was a small gap between the nozzle and the hot end and I did get it up to 280 for the removal and install. I think I just need to disassemble the whole thing. And maybe order a backup hotend and nozzles.

Thanks,

RE: Issue after nozzle change.

You caught it early on, so things aren't so bad. Your thermistor and heater cartridge look to be in good shape, so just clean it off carefully.

Try re-tightening at 285C. Be sure to grip the block firmly (I like a 16mm open wrench/spanner) and avoid any twisting or bending that might snap the heatbreak.

Next time you get a chance, you might want to put the printer on a table with good light and disassemble the extruder to remove the hotend. I'd recommend keeping a spare nozzle, heatbreak, thermistor and heater cartridge on hand, possibly even a spare heater block. If this had been worse, you could have wound up with one difficult-to-separate blob.

Good catch!

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: Issue after nozzle change.

Are you sure on the gap between the nozzle and the block heater ?

And i see a flow like a filament (black and an another greyish) what is that ? like a leak from above ... ! hence my previous question (the gap : important).

Have you seen the picture of my response (buse = nozzle) ? is it clear to you ?

Please look at attentively.

Regards. Claire.

RE: Issue after nozzle change.

I'm pretty sure I had a gap between the block and the nozzle, as I was scraping paint out of there with a pick. I did take the heating element out of the extruder assembly and it appeared the filament was coming out from above. It was mostly Black PETG, with some Green PLA and White PLA. I have scraped off what I could and will assemble it tomorrow.