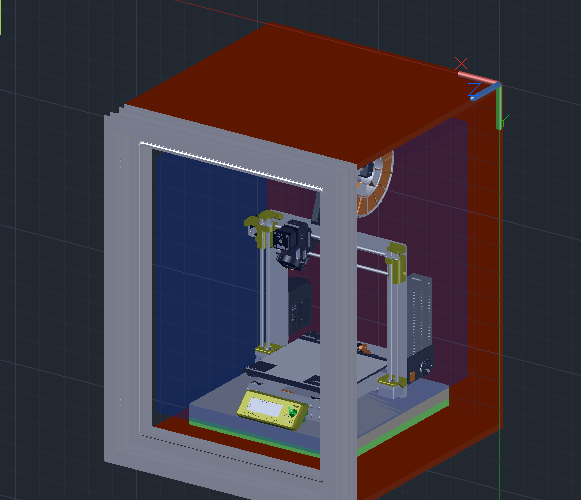

I made a really sturdy enclosure out of plywood and with a real glass window.

I used the wait time for my new printer to already build an enclosure. My old printer was always a little bit dusty and I wanted a place for all the components. The lack enclosure is a great idea, but it wasn´t for me. So I made this cabinet using 20mm plywood and a real glass window. The smallest opening windows in Germany are 60x60cm but this one is 60x90cm. It was reduced from 75€ to 50€ because it was displayed at the store. I am sure you can get such cheap windows for the same price on ebay. The benefit is that they come with hinges and a locking handle already installed. The real glass is also scratch resistant and they are most often tripple glazed so they are well insulated.

Inititally I planned to hang this up in the utility room in the basement, but now it lives in the guest room. Someday it will probably have to move, but having it in the flat is much easier to keep an eye on it.

I recommend adding a power strip to the underside.

RE: I made a really sturdy enclosure out of plywood and with a real glass window.

Was following along thinking I might get into woodworking until you pulled out the forklift. Definitely beyond my skill level! Very nice cabinet. I like the paver stone + foam to dampen sound.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: I made a really sturdy enclosure out of plywood and with a real glass window.

@bobstro

You can definitley get into woodworking. Never mind the forklift. I have been in this hobby for a long time and its not just a hobby. I make commercial drawer slides for RVs in that workshop. So any tool is a business expense. Hence the forklift.

RE: I made a really sturdy enclosure out of plywood and with a real glass window.

Hello Max, I'm trying to build the same exact enclosure you're showing in your videos as I live in a very small apartment, and for me it's a super huge plus being able to roll the enclosure by night to my tiny kitchen and let the printing happen there, to avoid any noises.

I'm designing it first in 3D to avoid any messups. Quick question, why have you built the bottom part of the enclosure "recessed", instead of making the box surround fully the frame of the Window? Is there any advantage to that? (v.s just making it all around and screwing the bottom part in the same way you've screwed the top and the sides...)