high temp and quality printing upgrades mods?

Hello,

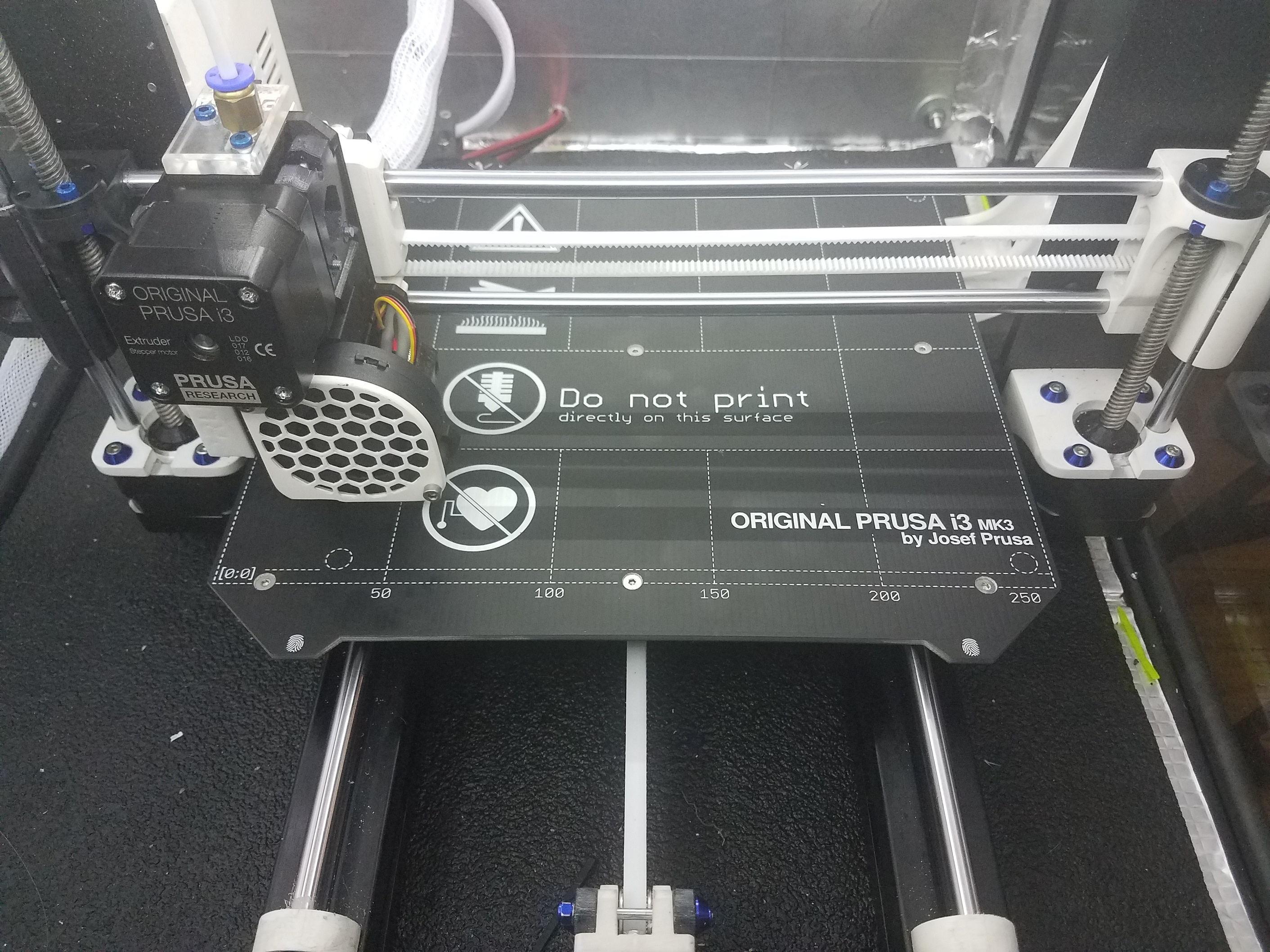

I bought an mk3 I3 this year for my PHD, and with my director we would like to take some upgrades in it to be able to print in the high temp filaments and have a better printing quality.

For this I know that there is a lot of modification that we can do to the printer,

And I would like some help from people with more experienced in the subject,

(Please correct me if I am wrong with something or if there is any better option.)

First of all, the print quality,

a. The quality is really important as we are going to print small but very detailed prints,

a.1. The pro pack nozzels from E3D, as sometimes they need to be really detailed the 0.15mm could be a good option and also the hardened steel ones could help us to print in some other composite materials ( https://e3d-online.com/nozzle-pro-pack )

a.2. I saw that a user (travis.e5) suggested to change the rods:

Misumi Bearings and Shafts:

(10) LMU8 Linear Bushings

(2) SFJ8-320 Rods

(2) SFJ8-330 Rods

(2) SFJ8-370 Rods

*but I saw that the best approach would be the linear rails but it would be some big modifications and I didn’t find anyone that documented this…

a.3. Changing the belts for higher quality ones (any recommendation? or the originals are good enough?)

a.4. Also add a big block of concrete to fix the printer to it so I can take a little bit more the vibration of the printer

a.5. Also make some 3D prints to change from the originals ones as:

Filament Sensor Cover Upgrade ( https://www.thingiverse.com/thing:2748862 )

Y axis Adjustable Belt Tensioner ( https://www.thingiverse.com/thing:2786671 )

Reinforced 3 bolt Y axis motor mount ( https://www.thingiverse.com/thing:2809788 )

X stepper motor strain relief ( https://www.thingiverse.com/thing:2543380 )

External Ventilator Cover ( https://www.thingiverse.com/thing:2746072 )

Angled fan mount, body extruder and the new cooling fan mount from prusa labs ( https://shop.prusa3d.com/forum/general-discussion-announcements-and-releases-f61/new-printed-parts-version-r3-t23017.html )

a.6. the full bear upgrade for a frame with better frame rigidity ( http://www.ratrig.com/prusa-i3-bear-upgrade-v2-0-frame-kit.html or https://www.thingiverse.com/thing:2808408 ) (with all the optional parts to make it even better https://github.com/gregsaun/prusa_i3_bear_upgrade/blob/master/optional_parts.md )

b. Second big point is to make possible to print in high temperature materials, like peek

b.1. First of all with the enclosure I would isolate it and also add a heater that regulates the temperature (with an Arduino or something like that) and also a dehumidifier and dust filter.

b.2. Move all the electronics that can be moved outside of the enclosure (for printing peek the inside temperature needs to be around 90°C) so better to take all that we can take out side.

b.3. Changing the hotend? I thought about putting a dual extrusion head, and make it possible to reach high temperatures:

sometimes I am not going to print in high temps plastics so a second head for the PVA would be cool.

And as printing in peek I saw that we need at least 380°C and I think we can go only to 290°C with the original hotend of the printer? (I saw that the Intamsys Funmat HT hotend goes up to 450°C a specialized 3D printer for PEEK)

I thought to go with a chimera+ with water cooling system, 24V and a cooper heater block from E3D so I will be able to:

Print “low temp” thermoplastics with PVA supports

Go up in temp to be able to print with high temps plastics

Or would be better to go with the MMU from prusa and upgrade the V6 with a water cooling system and another heater block?

b.4. Maybe uploading the heating bed to go up to higher temps? I am not 100% sure of the temperature needed but from the Intamsys Funmat HT theirs goes up to 160°C

• Also change the different printed parts with others ones from others materials for high temperature resistance not sure that the PETG used from originals is going to sustain high temps of the enclosure even if it is for small prints

• Make a glass bed too for when printing to hot temperatures that the normal bed would not resist (?) not sure at all but as it coated with PEI power it would be reasonable that it would not resist printing with PEEK (but I didn’t find anything about the subject).

i am going to keep track of the different suggestions and modify the list of things to do in the original post 🙂

Re: high temp and quality printing upgrades mods?

To print PEEK you will need to change the heater block and nozzle. You will need the plated copper heater block and nozzle from E3D. This is also available through Matter Hackers if you are in the US.

For high temperatures E3D also recommend fitting their V6 PT100 Upgrade Kit. This may not be necessary. If you fit the PT100 kit you will have to compile your own firmware. The source code for the firmware already includes the change you need to make only one line needs to be uncommented. If you wish to go the water cooled route the water cooled Chimera+ heatsink is the way to go fitted with a single heater block. I am not sure if anyone has designed a Prusa i3 MK3 compatible extruder body to take it yet. However it would be an easy design starting from the R2 body. One thing to note is that the Einsy board can only handle one heater block. So that the second heater block mount will not be used on the Chimera+. This is the E3D recommended upgrade path for V6 and Volcano water cooling.

If you decide on using a Volcano heater block rather than a V6 block. Third parties such as Aliexpress have small diameter nozzles available for the Volcano. I have no idea how good they are however.

I just looked at External Ventilator Cover it does not look compatible with the angled fan mount.

Regards,

Martin

Martin Wolfe

Re: high temp and quality printing upgrades mods?

I'd really worry about the required enclosure temps and your printed parts, not to mention the steppers.

These madmen at nasa apparently got a taz6 printing with PEI

Re: high temp and quality printing upgrades mods?

To print PEEK you will need to change the heater block and nozzle. You will need the plated copper heater block and nozzle from E3D. This is also available through Matter Hackers if you are in the US.

For high temperatures E3D also recommend fitting their V6 PT100 Upgrade Kit. This may not be necessary. If you fit the PT100 kit you will have to compile your own firmware. The source code for the firmware already includes the change you need to make only one line needs to be uncommented. If you wish to go the water cooled route the water cooled Chimera+ heatsink is the way to go fitted with a single heater block. I am not sure if anyone has designed a Prusa i3 MK3 compatible extruder body to take it yet. However it would be an easy design starting from the R2 body. One thing to note is that the Einsy board can only handle one heater block. So that the second heater block mount will not be used on the Chimera+. This is the E3D recommended upgrade path for V6 and Volcano water cooling.

If you decide on using a Volcano heater block rather than a V6 block. Third parties such as Aliexpress have small diameter nozzles available for the Volcano. I have no idea how good they are however.

I just looked at External Ventilator Cover it does not look compatible with the angled fan mount.

Regards,

Martin

Well from the info you gave me actually the two nozzel would be really problematic as it would be only one heat block (it would be more like a pseudo mix between a cyclops and a chimera).

The best solution would be to use the prusa MMU 2 with the original V6 from the prusa, with the upgrades from E3D:

-the cooper plated heat block and nozzel

-the PT100 V6 upgrade

But I didn’t get what you meant by the “This is the E3D recommended upgrade path for V6 and Volcano water cooling”. You meant that E3D recommends that if you want a V6 or volcano water cooled the way to go would be to use a chimera+ using only one hotend? This is awfully complicated solution ahahaha.

i thought about doing something like this, to adapt the original in the I3 to a water cooling system ( with the water cooling system from E3D) ( https://www.thingiverse.com/thing:247599 )

Thanks for telling me about the external ventilator cover I have been doing the list since some days and it was before the upgrade from prusa.

I'd really worry about the required enclosure temps and your printed parts, not to mention the steppers.

These madmen at nasa apparently got a taz6 printing with PEI

Yes, you are right about that, I thought about the PC but reading the article that you post it it would be problematic, in that case I would go with some CNC machined pieces maybe. Sadly at the moment we have a 3axes CNC only….

For the stepper motors I thought about doing some cover like the ones he used and use a cooling system too ( I forgot to post it in the original post… ).

Re: high temp and quality printing upgrades mods?

I actually built a printer specifically around this mentality and there are huge benefits and drawbacks. Its been a learning experience. I have lately been printing with PPS (Polyphenylene Sulfide) and PEKK with minor issues, but it works! PEKK is the max I will go with the hotend at 360C. I mainly did it so I can thow about anything at it. I primarily print PC/CF which requires the hotend at 305C.

Here is what I did so far

Complete hotend change - E3D gold edition with a titanium heatbreak and copper block. Also, a Olsen Ruby with Capricorn tube in the heatbreak.

Extruder parts- All printed from CF/PC. Was a Nylon/CF, but I started to scorch parts by the copper block. The filament sensor cap is cut from acrylic so I can kinda see what is going on. I didn't opt for the angled cooling fan due to the fact the only time I use cooling is for PLA which is rarely ever. Usually if you are printing over 300C and the cooling fan is on it will send false readings and you will get a thermal runaway warning. I do like the new extruder cover ventilation and I will be converting to that soon.

Z axis parts- All PC/ASA, PC/CF or PC parts.

X axis parts - I opted for igus linear bearings for the carriage and so far they have been great ( 3 months non-stop printing). I used a poly/steel-core belt with a 16T idler. I have been told many times that I will have issues with it, but so far its been great! The idler and motor mounts are a PC or CF/PC.

Y axis parts - Again, All PC/CF or some PC. I used a custom belt idler and also the poly/steel belt.

Pretty much modified everything..... but the key was temperature control. I used a old AV rolling cabinet for my enclosure and added a couple lasko heaters. This is all controlled via octoprint enclosure plugin to keep things regulated. Still a work in progress. Never really had a issue with the stepper motors except the Extruder motor overheating occasionally. Heatsinks fixed that 🙂

Re: high temp and quality printing upgrades mods?

X axis parts - I opted for igus linear bearings for the carriage

which flavor did you use, I'm guessing one of the metal jacketed ones?

Pretty much modified everything..... but the key was temperature control. I used a old AV rolling cabinet for my enclosure and added a couple lasko heaters. This is all controlled via octoprint enclosure plugin to keep things regulated. Still a work in progress. Never really had a issue with the stepper motors except the Extruder motor overheating occasionally. Heatsinks fixed that 🙂

Do you use the heated enclosure for PC as well? I've been struggling to get layer adhesion with PC comparable to what I normally get with PETG.

Re: high temp and quality printing upgrades mods?

X axis parts - I opted for igus linear bearings for the carriage

which flavor did you use, I'm guessing one of the metal jacketed ones?

Actually I just used the ol plastic ones Drylin RJ4JP-01-08. They seem to take the heat very well. The only bearings that I changed are the Z axis bearings. Those I went with Mitsumi. The Z axis is very sensitive and It wasn't worth my time trying to adjust.

Pretty much modified everything..... but the key was temperature control. I used a old AV rolling cabinet for my enclosure and added a couple lasko heaters. This is all controlled via octoprint enclosure plugin to keep things regulated. Still a work in progress. Never really had a issue with the stepper motors except the Extruder motor overheating occasionally. Heatsinks fixed that 🙂

Do you use the heated enclosure for PC as well? I've been struggling to get layer adhesion with PC comparable to what I normally get with PETG.

Yes! Only way to really print PC in my opinion. I use two different steel sheets. The smooth PEI that came stock I use for ABS and PETG. The PC and PEKK I use a custom powdercoated PEI sheet I bought 3rd party with a little gluestick. I have yet to have a part come up on that sheet, but the smooth PEI is tricky. The temperature inside the enclosure i keep at around 60C for PC. I try to go for about 70C for PEKK.

Re: high temp and quality printing upgrades mods?

Here is what I did so far

Complete hotend change - E3D gold edition with a titanium heatbreak and copper block. Also, a Olsen Ruby with Capricorn tube in the heatbreak.

So to make it clear, the E3D gold edition ( https://e3d-online.com/v6-gold-hotend )

The titanium heat break ( https://e3d-online.com/titanium-heat-break )

Copper blocks and capricorn tube, comes from the stock with the gold edition,

And for better results (if not using the CF filaments) would be the copper nozzel too ( https://e3d-online.com/v6-nozzles-plated-copper )

did you upgrade the hotend with the v6 PT100 upgrade? ( i couldnt find if the gold edition has the upgrade already, but either way at least i would need the card for it... ) ( https://e3d-online.com/v6-pt100-sensor-kit )

Extruder parts- All printed from CF/PC. Was a Nylon/CF, but I started to scorch parts by the copper block. The filament sensor cap is cut from acrylic so I can kinda see what is going on. I didn't opt for the angled cooling fan due to the fact the only time I use cooling is for PLA which is rarely ever. Usually if you are printing over 300C and the cooling fan is on it will send false readings and you will get a thermal runaway warning. I do like the new extruder cover ventilation and I will be converting to that soon.

Did you though about a water cooling system? Like this one I found for the V6 where you need to change the heatsink of it ( https://well-engineered.net/index.php/en/86-community-water-cooling )

Z axis parts- All PC/ASA, PC/CF or PC parts.

X axis parts - I opted for igus linear bearings for the carriage and so far they have been great ( 3 months non-stop printing). I used a poly/steel-core belt with a 16T idler. I have been told many times that I will have issues with it, but so far its been great! The idler and motor mounts are a PC or CF/PC.

Y axis parts - Again, All PC/CF or some PC. I used a custom belt idler and also the poly/steel belt.

For the igus linear bearings I think is the way to go, everybody is using them as the upgrade for the linear bearings. And for the belt, I coulndt find any really good recommendation of a high end belt (as I work in a university lab, at the end of the year we need to spend our budget, yes , we NEED or we loss 25% of it… so I don’t mind in paying a little bit more for some high end belts even if they are much more expensive…).

Pretty much modified everything..... but the key was temperature control. I used a old AV rolling cabinet for my enclosure and added a couple lasko heaters. This is all controlled via octoprint enclosure plugin to keep things regulated. Still a work in progress. Never really had a issue with the stepper motors except the Extruder motor overheating occasionally. Heatsinks fixed that 🙂

Yes, I really need to find a good enclosure and make it reliable with the temperature… I didn’t know about the pluging for controlled with octoprint, I will have a look about it (so octoprint upgrade would be…. Oh god ahahahaha it is going to be a long journey). About the motors I though that maybe I would go with something like the one that used in nasa’s papper, with a cooling system for the motors too.i didn’t saw any heatsink in the extruder motor in the photo you took it out ?

And you would highly recommend PC/CF for the parts? You have any good branch of it in recommendation?

Where did you bought the 3rd party powdered PEI sheet ? :O and printing in peek doesn’t wear it?

Thanks for all the info! I thing that I will keep gathering all the info that I could have till end of the year and after document everything in a guide

Re: high temp and quality printing upgrades mods?

Here is what I did so far

Complete hotend change - E3D gold edition with a titanium heatbreak and copper block. Also, a Olsen Ruby with Capricorn tube in the heatbreak.

So to make it clear, the E3D gold edition ( https://e3d-online.com/v6-gold-hotend )

The titanium heat break ( https://e3d-online.com/titanium-heat-break )

Copper blocks and capricorn tube, comes from the stock with the gold edition,

And for better results (if not using the CF filaments) would be the copper nozzel too ( https://e3d-online.com/v6-nozzles-plated-copper )

did you upgrade the hotend with the v6 PT100 upgrade? ( i couldnt find if the gold edition has the upgrade already, but either way at least i would need the card for it... ) ( https://e3d-online.com/v6-pt100-sensor-kit )

Extruder parts- All printed from CF/PC. Was a Nylon/CF, but I started to scorch parts by the copper block. The filament sensor cap is cut from acrylic so I can kinda see what is going on. I didn't opt for the angled cooling fan due to the fact the only time I use cooling is for PLA which is rarely ever. Usually if you are printing over 300C and the cooling fan is on it will send false readings and you will get a thermal runaway warning. I do like the new extruder cover ventilation and I will be converting to that soon.

Did you though about a water cooling system? Like this one I found for the V6 where you need to change the heatsink of it ( https://well-engineered.net/index.php/en/86-community-water-cooling )

Z axis parts- All PC/ASA, PC/CF or PC parts.

X axis parts - I opted for igus linear bearings for the carriage and so far they have been great ( 3 months non-stop printing). I used a poly/steel-core belt with a 16T idler. I have been told many times that I will have issues with it, but so far its been great! The idler and motor mounts are a PC or CF/PC.

Y axis parts - Again, All PC/CF or some PC. I used a custom belt idler and also the poly/steel belt.

For the igus linear bearings I think is the way to go, everybody is using them as the upgrade for the linear bearings. And for the belt, I coulndt find any really good recommendation of a high end belt (as I work in a university lab, at the end of the year we need to spend our budget, yes , we NEED or we loss 25% of it… so I don’t mind in paying a little bit more for some high end belts even if they are much more expensive…).

Pretty much modified everything..... but the key was temperature control. I used a old AV rolling cabinet for my enclosure and added a couple lasko heaters. This is all controlled via octoprint enclosure plugin to keep things regulated. Still a work in progress. Never really had a issue with the stepper motors except the Extruder motor overheating occasionally. Heatsinks fixed that 🙂

Yes, I really need to find a good enclosure and make it reliable with the temperature… I didn’t know about the pluging for controlled with octoprint, I will have a look about it (so octoprint upgrade would be…. Oh god ahahahaha it is going to be a long journey). About the motors I though that maybe I would go with something like the one that used in nasa’s papper, with a cooling system for the motors too.i didn’t saw any heatsink in the extruder motor in the photo you took it out ?

And you would highly recommend PC/CF for the parts? You have any good branch of it in recommendation?

Where did you bought the 3rd party powdered PEI sheet ? :O and printing in peek doesn’t wear it?

Thanks for all the info! I thing that I will keep gathering all the info that I could have till end of the year and after document everything in a guide

Try to answer all of these that I can:)

That list is correct! You dont have to have a gold edition, but I figured why not:)

The heatbreak is actually a Winsinn from amazon, and I am super impressed by the quality. It is identical to my friends E3d one. Way cheaper too!

The nozzle is something I switch around. I have a copper plated nozzle, but I have been using the Ruby.

Yes I upgraded to a pt100 with the amp. You will have to compile your own firmware, but it is super easy. Getting ready to add one to the heatbed soon.

I highly recommend atleast some sort of PC for printer parts. My stock Mk3's for work melted the stock extruder bodies in one week. I printed those out of Taulman 680 and those have held up great but I wanted something more extreme and ridgid for my build. That is where 3dxtech filament came into play. They have a PC/CF filament that is freaking amazing!!!

Yea I will post some newer pictures of the heatsinks on the extruder motor, but yes... stuff gets hot. I have yet to relocate the ensy so I have a fan blowing on it at the moment, but the x, y and z motors don't really heat up that bad. You won't have problems unless you are going 80-90C in the chamber... then you start missing steps. The 3rd party plate I got from amazon is https://www.amazon.com/gp/product/B07DVSGVQB/ref=oh_aui_detailpage_o08_s00?ie=UTF8&psc=1

I really don't print PEEK... I print PEKK though... In my opinion wayyyy better. Check out https://www.3dxtech.com/

Re: high temp and quality printing upgrades mods?

I had to modify my Prusa for the very similar set of reasons. I'm working on my MSc and the project requires some really tiny parts with good accuracy. Anyway, cut the story short.... the solution to overheating stepper motors is the small but decent water cooling rig. You can buy cheap gpu water blocks

https://www.ebay.co.uk/itm/Computer-Components-Liquid-Cooling-Block-40-x40x12mm-Aluminium-for-CPU-GPU-BB3/123095312877?hash=item1ca90d69ed:g:9S4AAOSwV99a3bdx

they are aluminium but perform very well. I changed the double thermaltake pumps for a single D5 pump:

https://www.overclockers.co.uk/ocuk-tech-labs-18w-ddc-pump-12v-ddc-3.2-500lph-wc-17z-tl.html

and it works like a charm. Just make sure to workout the airflow to the rads and a good layer of thermal paste between steppers and blocks.

I have a double enclosure with a 50mm layer of compressed mineral wool that insulates the heat from leaving the chamber.

It is basically Ikea lack table with walls and top enclosed in a large Ikea sink cupboard. The reason for that funny PVC window (still need to spray it black and straighten the corner damaged during the postage) is the argon gass which nicely insulates the glass. There is a 24V/250W heater:

https://www.ebay.co.uk/itm/12-24V-PTC-Cars-Fan-Air-Heater-Constant-Temperature-Heating-Element-Heaters/172773930868?hash=item283a20f774:m:mR23yONUgDYAAqdPWZI6QNQ

set in the high temperature silicone and with two large tubine blowers pushing the air through it. it is used only for an initial heating (to get the chamber to 60degrees). When I print ASA, Nylon or ABS with bed on 100deg the temperature inside stays fixed at 60deg without additional heating.

However, as you can see there is a PID controller for the heater (which can reach much higher temperatures) that can keep the temperature at required level:

https://www.amazon.co.uk/Inkbird-Temperature-Controller-ITC-100RH-Thermocouple/dp/B00ADEAAD0/ref=sr_1_2?ie=UTF8&qid=1533654194&sr=8-2&keywords=pt100+pid

40W heating element and heatbed are switched by mosfets external to Rambo.

650W second hand PSU seems more than sufficient for the task.

All controlled from the RPi via Octoprint.

There is few other mods that I had to make like bowden tube but if you are interested in more info, just drop me an email and we can talk about it further.

I will try to find some time to finish the mods and add watercooling to the head, because it won't take much effort now with everything set in place.

I have also a container for filaments with Moisture Absorber which is not on the photo.

Quality qith 0.25mm nozzle and the layer adheision is amazing.

It took a while to work out the settings but it was so worth it.

Re: high temp and quality printing upgrades mods?

First of all, WOW, second thanks for the answer and third sorry for taking soo time to answer….

I had to modify my Prusa for the very similar set of reasons. I'm working on my MSc and the project requires some really tiny parts with good accuracy. Anyway, cut the story short.... the solution to overheating stepper motors is the small but decent water cooling rig. You can buy cheap gpu water blocks

https://www.ebay.co.uk/itm/Computer-Com ... SwV99a3bdx

they are aluminium but perform very well. I changed the double thermaltake pumps for a single D5 pump:

https://www.overclockers.co.uk/ocuk-tec ... 7z-tl.html

and it works like a charm. Just make sure to workout the airflow to the rads and a good layer of thermal paste between steppers and blocks.

First of all I though about using the system of E3D, ( https://e3d-online.com/water-cooling-kit ) I though that the best would be two of them, one for the hotend and one for the motors no?

So something like this

Water cooling system (12V) x2 ( https://e3d-online.com/water-cooling-kit )

Aluminium blocks x4 (for all the motors)

Thermal paste for the blocks

Water cooling system for the hotend V6 x1

shield to be able to control 12V with the Pi (?) x2

I have a double enclosure with a 50mm layer of compressed mineral wool that insulates the heat from leaving the chamber.

It is basically Ikea lack table with walls and top enclosed in a large Ikea sink cupboard. The reason for that funny PVC window (still need to spray it black and straighten the corner damaged during the postage) is the argon gass which nicely insulates the glass.

The PVC window is not a bad idea at all actually I find it classy and also functional, I am going to have a look if I can find one like that and adapt it to the aluminum profiles I am thinking to use for the structure of the enclose. wich size it is the one that you used? the printer can pass by it or it is too small?

There is a 24V/250W heater:

https://www.ebay.co.uk/itm/12-24V-PTC-C ... qdPWZI6QNQ

set in the high temperature silicone and with two large tubine blowers pushing the air through it. it is used only for an initial heating (to get the chamber to 60degrees). When I print ASA, Nylon or ABS with bed on 100deg the temperature inside stays fixed at 60deg without additional heating.

However, as you can see there is a PID controller for the heater (which can reach much higher temperatures) that can keep the temperature at required level:

https://www.amazon.co.uk/Inkbird-Temper ... =pt100+pid

40W heating element and heatbed are switched by mosfets external to Rambo.

650W second hand PSU seems more than sufficient for the task.

I haven’t understand really well about the heater (sorry I have never worked with electroics in my life before…)

the list would go like this:

the 24V/250W heater

PID controller

The 650W PSU

And turbine blowers x2

And this part is what I am completely lost…. “40W heating element and heatbed are switched by mosfets external to Rambo.”

All controlled from the RPi via Octoprint.

I assume that you used a PI3+B no?

There is any tutorial that you used for controlling the water cooling, the heaters and everything else from the octoprint? Even the turbine blowers :O? (What I would like to do is do it in a way that is everything automatized but I have never worked with octoprint….( yes I have a long path to walk ahahaha…)

About that the speed of the pumps and the fans inside the chamber is all controlled by the octoprint? (I know that you said “all controlled from the RPi via octoprint but what I would like to know it is, when you try to print I don’t know, ASA you send the file to octoprint saying is ASA and the Pi controlles everything (automatically) ? the inside temp, the pumps the temps of the motors everything? Like you are printing like you would print normally with PLA with a stock prusa?

Thanks for everything, and sorry for bothering so much

Re: high temp and quality printing upgrades mods?

I think that fan and extruder modificatios could be helpful?

https://www.thingiverse.com/thing:2076234

https://www.prusaprinters.org/prusa-research-summer-update-2018/

RE: high temp and quality printing upgrades mods?

Hi krzysztof.s5

Did you had to do somthig in the Firmware?

RE: high temp and quality printing upgrades mods?

Please and thanks