Fix for Squeaky Extruders, especially when printing PETG

Hi all! When I received my Mk3 in July this year, it was fantastic. Fun to build, printed great, and was quiet - except for one brutal squeak from the extruder body when printing in PETG. If you've ever handled PETG filament (or had a 24- or 36-pack of plastic water bottles in the backseat of your car), you know it makes a very distinct sound when the copolyester is rubbed against itself. It sounds halfway between a bad wheelbarrow wheel and a chatty mouse.

This is the best video/audio recording I've found of the squeak: - note that it is especially prevalent on fast extruder E-axis moves like retracts and fine infill movements.

My kit arrived with the B6/R2 parts, and I needed to print the R3 parts. I printed them and rebuilt the extruder, hoping that would resolve the squeak. It didn't go away, however. Everything printed fine... it was just annoying.

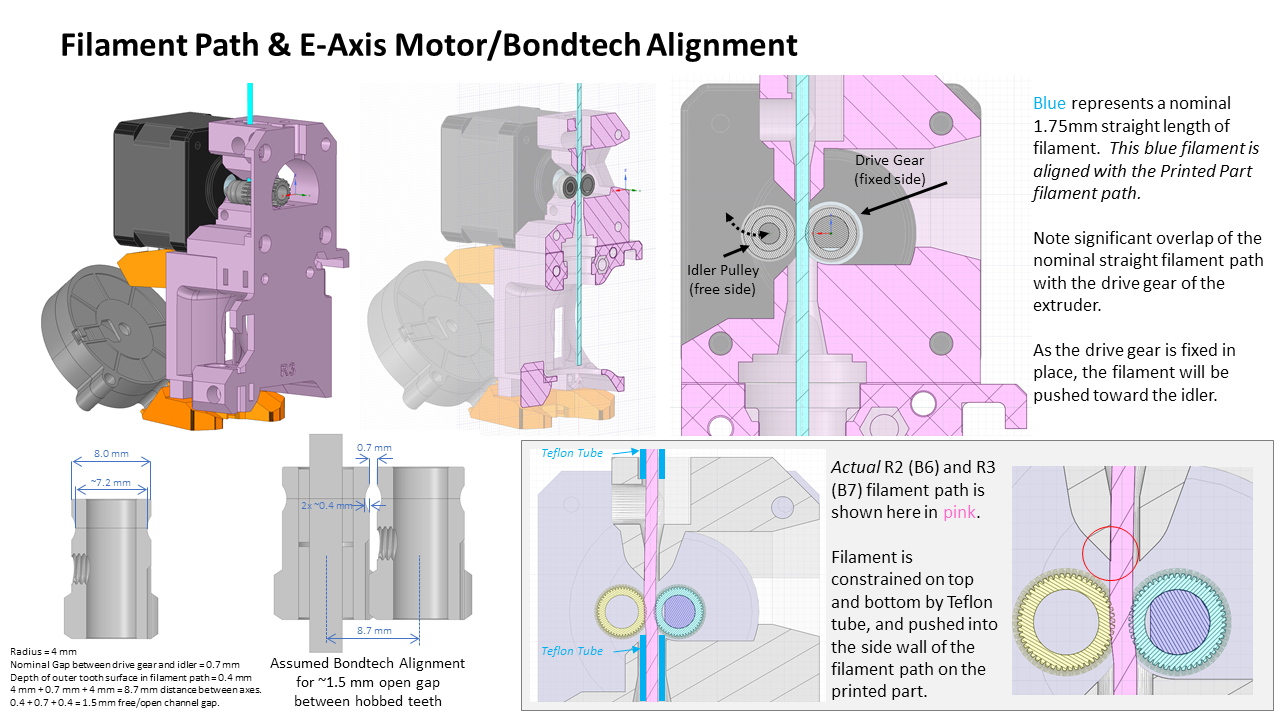

When Prusa posted the .stp CAD files for the R3 extruder body, I did some poking around in a CAD tool (using other models for the bondtech gears and a NEMA17 stepper motor). I modeled a straight piece of filament in the extruder to check path alignment. Here's what I saw:

That red-circled area was the problem spot - PETG filament was rubbing against the PETG body of the extruder, causing a squeak. The filament path didn't seem properly lined up with the stepper motor/bondtech gear combo.

Another thing to note - the cross-section view in the image above shows the side wall (not the top or bottom) of the filament path hole when it is oriented on a print bed. The squeak or friction spot inside the extruder body wasn't the result of a blob of printed filament or a bridge that drooped into the filament path.

When viewed from the top, the filament path looks like this:

It's possible to see that the drive-side of the bondtech gears intrudes too far into the filament path.

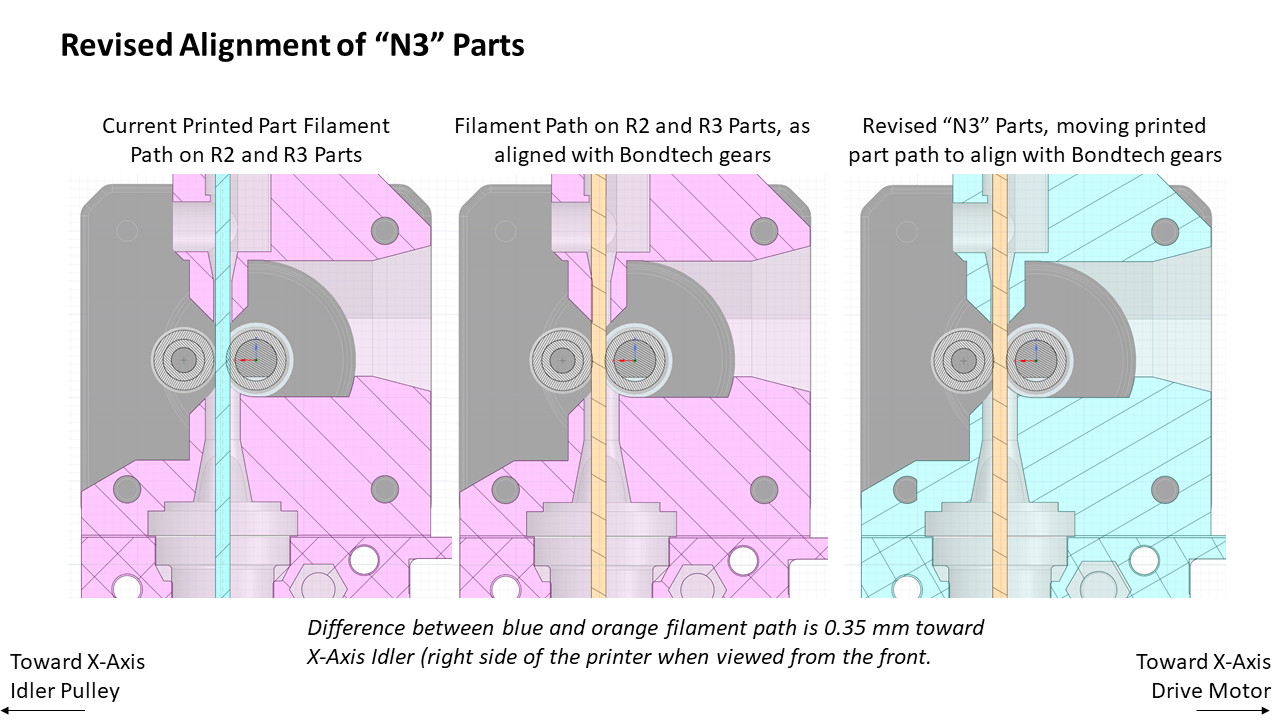

I remodeled the top half of the extruder body, shifting the filament path relative to the stepper motor/drive gear by 0.35mm (toward the X-axis idler). I probably could have shifted it by .40mm, but I didn't want to get too crazy - there's still some room for side-to-side tolerance already in the printed part design.

The reworked part models can be found here (both .stl and .stp/.step files are posted): MyMiniFactory. Note that these parts have been marked "N3" to distinguish them from the official R3 parts.

Please let me know if you end up building/testing/installing these parts - I've been printing with them since August now and now PETG sounds the same as PLA and ABS - nice and quiet. I have a hunch that this tweak may help with printing flexible filaments, but I haven't had the chance to test that yet. If you do, I'd love to hear about it.

Thanks! You guys are a great community and have been very helpful to me!

MyMiniFactory (Functional Parts and Mods): https://www.myminifactory.com/users/butterworthdesign

Thingiverse (Fun Designs and Remixes): https://www.thingiverse.com/uscbutterworth/designs

Twitter: @USCbutterworth https://twitter.com/USCbutterworth

Re: Fix for Squeaky Extruders, especially when printing PETG

I think I need to point out that I'm not the first to have this idea - I found this page on github after I had done the modeling and installed the revised parts on my machine.

MyMiniFactory (Functional Parts and Mods): https://www.myminifactory.com/users/butterworthdesign

Thingiverse (Fun Designs and Remixes): https://www.thingiverse.com/uscbutterworth/designs

Twitter: @USCbutterworth https://twitter.com/USCbutterworth

Re: Fix for Squeaky Extruders, especially when printing PETG

A very brief update since I have now had a chance to print with TPU. My first try at a Rocktapus, printed with AmazonBasics Red TPU turned out absolutely fantastic, just by using a stock flexible filament profile that I found in Slic3r PE without any further profile modification.

I tried to print at some ludicrous speed as well, about 65 mm/s by my very rough estimation (volume rate was set to 6mm^3/s to eliminate that bottleneck). Print quality obviously suffered greatly, but the extruder never jammed or spit filament out its sides.

The only issue I encountered and tip that I could give would be to not use the "Load Filament" option from the menu. The initial movement appears to be a bit too quick for flexibles - it's probably more reliable and well advised to manually (using the move E-axis menu option, and slowly turning the knob on the printer) slowly load the filament.

Thanks all, and I hope this is helpful.

MyMiniFactory (Functional Parts and Mods): https://www.myminifactory.com/users/butterworthdesign

Thingiverse (Fun Designs and Remixes): https://www.thingiverse.com/uscbutterworth/designs

Twitter: @USCbutterworth https://twitter.com/USCbutterworth

Re: Fix for Squeaky Extruders, especially when printing PETG

Thank you for this! I just started running into this issue after printing an entire spool of Hatchbox white PETG. I thought my issues was with the PTFE tube rubbing on the bontech gears. So I removed the hot end and flipped the PTFE tube around since I saw that it was deformed (wasn’t a perfect circle at the opening). But the squeak came back, but not as loud. I will try printing out your updated solution and see if the issue comes back.

I will print out the stl files that you uploaded on MyMiniFactor and return with results.

I do have one question for you though. Do I just need to print out the two following sql files?

-extruderbody-n3-alignfilamentpath-v1-1-oriented

-repaired_extrudercover-n3-alignedfilamentpath-oriented

Or do I need to print out all 5 stl files?

Attached is a photo of what I saw and I thought that was the problem.

Thanks,

David

Re: Fix for Squeaky Extruders, especially when printing PETG

I do have one question for you though. Do I just need to print out the two following sql files?

-extruderbody-n3-alignfilamentpath-v1-1-oriented

-repaired_extrudercover-n3-alignedfilamentpath-oriented

You're correct, only those two are required. The original R3 print fan arm bracket thing should work fine if you have already printed it, and the new additional side bracket is also optional. There is also no physical difference between the R3 nozzle and my new fan nozzle once printed, so the original R3 nozzle should also be fine.

Thanks for your feedback!

Edit:

I flipped the PTFE tube around since I saw that it was deformed (wasn’t a perfect circle at the opening)

Yes, that's exactly what I saw, now that you reminded me. It's funny - I didn't actually connect the deformed PTFE tube with this issue (though it's certainly the cause). Thanks again!

Edit 2: also, people keep mentioning the PTFE tube rubbing against the bondtech gears causing a squeak - I don't think that it's physically possible for PTFE (Teflon) to cause a friction/rubbing squeak (think about the sound of utensils against a non-stick pan... I've never heard a teflon pan squeak). The static and dynamic coefficients of friction are the same (and relatively low) for teflon on most materials, which is why it's "slippery" - it doesn't stick to things, and it won't vibrate when rubbed against metal.

MyMiniFactory (Functional Parts and Mods): https://www.myminifactory.com/users/butterworthdesign

Thingiverse (Fun Designs and Remixes): https://www.thingiverse.com/uscbutterworth/designs

Twitter: @USCbutterworth https://twitter.com/USCbutterworth

Re: Fix for Squeaky Extruders, especially when printing PETG

There was another recent update after R3 which removes a lip just after the filament sensor (More important for the MMU2 but I hate when I hit it loading filament). (Released Approx Dec 3, mentioned page 39 of this guide: https://prusa3d.com/downloads/manual/prusa3d_manual_mmu2_eng_1_03.pdf ). Does this also include that update? And any way we can get that filament path a little tighter to the idler? I have some really soft filament which I struggle with.

Re: Fix for Squeaky Extruders, especially when printing PETG

There was another recent update after R3 which removes a lip just after the filament sensor (More important for the MMU2 but I hate when I hit it loading filament). (Released Approx Dec 3

That's interesting, and is the first I've heard of this. Do you have an updated .stl or other model from Prusa? The latest files posted on Github are still dated from August, 2018 (and that date matches the files in the Prusa i3 Printable parts .zip file from the official page.

In either case, I do not see a lip anywhere in the model beneath the filament sensor, in either my model or the official R3 model. I wonder if the "extruder upgrade parts supplied with MM2 that were shipped approximately before December 3, 2018" simply means that back stock of printed parts were shipped, and kits shipped after that date contained the newer (August) version of the part. See below for a cross section comparing the R3 and N3 parts:

In the printed part, I do see the potential for a "lip" to form or something that would cause resistance in the filament due to bridging across the top of the hole as the part is printed. I have added a feature that should address this, by using a "teardrop" shape for the tightest filament path section; that should move any lip out of the way. It is, however, best practice in my opinion to, after printing the new extruder body, take a 2mm drill bit (5/64") and insert it in the filament path while twisting by hand or a pair of pliers (no drill needed, really....) to ensure that the path above the gears is nice and clear.

I have some really soft filament which I struggle with.

Have you been struggling with the official R3 parts? Or have you tried my "N3" parts yet?

By "tighter", do you mean "lower", as in the opening moved further down and closer to the bondtech gears themselves? Or do you mean reduced diameter only?

If you haven't yet, I'd strongly suggest trying with my N3 parts - flexible filaments shouldn't really be limited by the path above the bondtech gears as long as you're not retracting several millimeters like a madman.... I've tested with retraction on, set to 1mm, and TPU printed just fine.

MyMiniFactory (Functional Parts and Mods): https://www.myminifactory.com/users/butterworthdesign

Thingiverse (Fun Designs and Remixes): https://www.thingiverse.com/uscbutterworth/designs

Twitter: @USCbutterworth https://twitter.com/USCbutterworth

Re: Fix for Squeaky Extruders, especially when printing PETG

I don't think that it's physically possible for PTFE (Teflon) to cause a friction/rubbing squeak

Turns out I'm wrong about this part - I cut some Capricorn XS tubing last night, and it did certainly squeak against a utility knife blade. This might be due to some of the additives in the tubing (it's not pure PTFE), but I stand corrected nonetheless. However, while the tube squeaked when cut, it had a different tone or sound than the distinct PETG/PETG friction sound.

MyMiniFactory (Functional Parts and Mods): https://www.myminifactory.com/users/butterworthdesign

Thingiverse (Fun Designs and Remixes): https://www.thingiverse.com/uscbutterworth/designs

Twitter: @USCbutterworth https://twitter.com/USCbutterworth

Re: Fix for Squeaky Extruders, especially when printing PETG

Sorry if this is a very noob question. I'm new to 3d printing and the mk3 is my first printer that I received a few weeks ago. I have significant "squeaking" just as in your video on mine using the PLA that came with my printer. Will printing these components help me for PLA as well? Thanks!

Re: Fix for Squeaky Extruders, especially when printing PETG

Will printing these components help me for PLA as well?

It's possible, but unfortunately I can't say 100% for sure! I think that if you've eliminated everything else (it's not belts, not bearings, not bondtech gears, and the gears are properly lubed), and the squeak happens only when the extruder motor is moving or switching direction, there's a really good chance they'll help.

There's no real downside I can see to using these parts, and filament is definitely easier to load and unload.

Note: the parts linked above are for Mk3 printers only - if you recieved a Mk3S, or want to use the C1/R4/Mk3S parts with the Mk3 filament sensor, see the parts linked here: https://www.myminifactory.com/object/3d-print-86329

Thanks, and good luck! If you do try the parts and they help (or if they don't) please reply again here so you can share your feedback.

MyMiniFactory (Functional Parts and Mods): https://www.myminifactory.com/users/butterworthdesign

Thingiverse (Fun Designs and Remixes): https://www.thingiverse.com/uscbutterworth/designs

Twitter: @USCbutterworth https://twitter.com/USCbutterworth