Re: Fix bed variance / warp using flat springs

I ended up cutting the 15mm springs in half with a Dremel tool, then using a good bench sander got them all to roughly 7.25mm. The sander also made the cut end pretty flat. Added some Vibra-Tite to the screws so they would hold position. Using the stock screws, they were all tightened until just touching the bed, then they were turned in 3.5 turns to get close to the stock spacers that were 5.5mm.

It dialed right in to .014mm variance and that's good enough for me.

Jim

Re: Fix bed variance / warp using flat springs

I ended up cutting the 15mm springs in half with a Dremel tool, then using a good bench sander got them all to roughly 7.25mm. The sander also made the cut end pretty flat. Added some Vibra-Tite to the screws so they would hold position. Using the stock screws, they were all tightened until just touching the bed, then they were turned in 3.5 turns to get close to the stock spacers that were 5.5mm.

It dialed right in to .014mm variance and that's good enough for me.

Jim

Glad that work to you 🙂

Springs give total freedom 😀

Re: Fix bed variance / warp using flat springs

Awesome idea you had!

This dialed right in with little effort and no hassles trying to fit conical washers near the magnets.

Thanks again,

Jim

Re: Fix bed variance / warp using flat springs

Awesome idea you had!

This dialed right in with little effort and no hassles trying to fit conical washers near the magnets.

Thanks again,

Jim

Would be nice users post the before and after mesh image map 🙂

Re: Fix bed variance / warp using flat springs

Ok, let's see if this works.

Before - Using stock spacers. I tried raising and lowering the Y rails with little success.

After - Using red die springs, 3mm x 6mm x 15mm cut in half. Stock screws.

Sorry for the change in MeshMap theme.

Jim

Re: Fix bed variance / warp using flat springs

Your initial variance not bad, much better than mine.

Still is always good to improve stuff 😉

Re: Fix bed variance / warp using flat springs

What would the ideal spring length be, such that compressing it would make it close to the 5.5mm stock spacer height?

Re: Fix bed variance / warp using flat springs

What would the ideal spring length be, such that compressing it would make it close to the 5.5mm stock spacer height?

A 10mm spring can be easy compressed to 5mm.

Re: Fix bed variance / warp using flat springs

What would the ideal spring length be, such that compressing it would make it close to the 5.5mm stock spacer height?

A 10mm spring can be easy compressed to 5mm.

Hi Tiago,

on AliExpress I found a seller who can offer me 10mm long red springs with OD 6mm and ID 3mm - I guess he could offer me other lengths maybe too.

So I would like to know: based on your success with this method: What is the ideal length if you could choose freely? Is it 10mm? Compressing them by 50% to get down to 5mm seems a bit brutal:-) Also I thought to maybe add washers to not scratch up the bed and the frame, so those would add to the height.

What is your opinion? Best regards,

Stahlfabrik

Re: Fix bed variance / warp using flat springs

...

Very nice work Tiago, I got some springs few weeks ago and was about to test them and write same kind of article than you. I have already tested something similar on MK2s/MK2.5 with serrated lock washers.

On MK2s/MK2.5 the problem is that the Y belt holder is used to maintain the bed and also use two point in the center and it is very hard to get the same tension on both. So what I did is that I drilled two new holes on the Y carriage, next to the original belt holder holes. Then I use a single screw in the middle of the belt from original holes and new holes to mount the Y belt holder. This has the advantage to reduce torque on the bearing because the belt holder is now closer to the dual bearings.

The other problem on the MK2s/MK2.5 is that the Y carriage does not have threads but threaded standoff instead. So I used non threaded standoff, longer screws and bolt under the Y carriage. All this make everything so easy to adjust the heated bed, even with serrated washers! Can wait to test this with my springs! Note that I am not sure this is possible on stock MK2s/MK2.5 because of the Z aluminum plate (I am using my Full Bear frame).

I am wondering if it could not be better to use a fixed point in the center, without spring. Did you try that?

I found a bit shorter springs here :

https://www.aliexpress.com/item/3D-printer-accessories-pressure-spring-hot-extruder-hot-bed-MK2B-MK3-MK2A-and-other-support-special/32849401447.html?spm=a2g0s.9042311.0.0.eaf94c4dl5kwQX

Re: Fix bed variance / warp using flat springs

Interesting links Greg, so 8mm is my guess already for an optimal length and your links just confirmed this a little:)

Just from the looks, the red springs that Tiago dug up seem a little more robust as the ones that you found - so that could be beneficial. But who knows.

The springs that you found are like 100times more cheap than the springs that I was offered though LOL

Re: Fix bed variance / warp using flat springs

Interesting links Greg, so 8mm is my guess already for an optimal length and your links just confirmed this a little:)

Just from the looks, the red springs that Tiago dug up seem a little more robust as the ones that you found - so that could be beneficial. But who knows.

The springs that you found are like 100times more cheap than the springs that I was offered though LOL

They looks good honestly but I have not tested them yet.

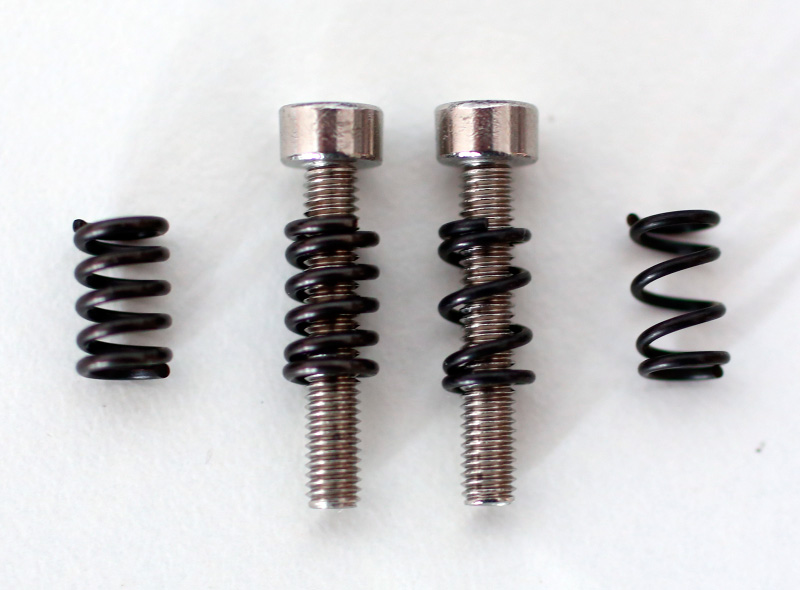

Here is one of the 100pcs springs pack on M3 screw :

Re: Fix bed variance / warp using flat springs

Those black springs look great.

How does one decide whether they are stiff enough?

Re: Fix bed variance / warp using flat springs

Those black springs look great.

How does one decide whether they are stiff enough?

This is hard to answer, Tiago should have a better idea than me. This need some testing to see if they are going to work or not. I think they need to be quite strong, to avoid movements of the bed during high speed movements with an heavy/tall printed part. But they should not scratch the heated bed nor weaken the threads in the Y carriage aluminum plate (aluminum thread can be weaken quite easily)

Re: Fix bed variance / warp using flat springs

is there any mileage in keeping a spacer in the middle and using springs on the other 8 points? the rigid point in the middle could reduce the chances of bed sway, with large prints!

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Fix bed variance / warp using flat springs

is there any mileage in keeping a spacer in the middle and using springs on the other 8 points? the rigid point in the middle could reduce the chances of bed sway, with large prints!

regards Joan

Yes it should be better to use a rigid standoff in the middle, it will act as a reference point. Plus it will give more rigidity to the moving bed. I could not have time to test it.

Standoff length should be between the longest and shortest size of the spring.

Re: Fix bed variance / warp using flat springs

Joan, yes I think too that this could be helpful!

I am unable to find 8mm length screws by the way of the red kind. I found a shop who offered 10mm length. But I think it is too long, if the middle is kept as the normal standoff. Because all other points would be needed to adjust to +- 5.5mm, so a starting length of 7 or 8 mm or so seems much better.

Re: Fix bed variance / warp using flat springs

I found a bit shorter springs here :

https://www.aliexpress.com/item/3D-printer-accessories-pressure-spring-hot-extruder-hot-bed-MK2B-MK3-MK2A-and-other-support-special/32849401447.html?spm=a2g0s.9042311.0.0.eaf94c4dl5kwQX

Have you ordered both - are they the same?

I really wonder if these springs and the stock middle standoff would not be working... But somehow I feel there is plenty potential to damage the bed:-)

Re: Fix bed variance / warp using flat springs

Have you ordered both - are they the same?

I really wonder if these springs and the stock middle standoff would not be working... But somehow I feel there is plenty potential to damage the bed:-)

yes both

the one from 100pcs seems better because stronger, but less adjustment range available. Here are some pics, 100pcs is on the left

Left one is 8mm relaxed, 5mm compressed

Right on is 8.5mm relaxed, 3.5mm compressed

I do not think they will damage the bed if you add a washer

Re: Fix bed variance / warp using flat springs

If I take the left one, standoff should have an ideal length of 8 - 5 + 5/2 + 2*0.5 (washers) = 6.5mm. So MK3 standoff + a washer