Diagnosing New Onset Heat Creep Jams on Slice Magnum

After nearly a year of trouble free extruder function, my Slice Magnum started suffering filament jams during long PETG prints. The filament would get firmly jammed.

Clearing jam by heating without cooling fan flow allowed removal of filament once temp above heat break was hot enough to melt the jammed filament. Immediately thereafter, it was very easy to push filament through extruder and out the nozzle with very little resistance. Ran cleaning filament through at high temp. Reset Bondtech gear tension.

Heat jammed again.

Tried allowing enclosure to be cooler by keeping doors ajar. This was never needed before, but going from 43C to 37C enclosure helped a bit. Some large jobs were doable, but would still jam unpredictably.

Full disassembly and cleaning of Hot End.

Seemed to help for a few days, but once more got some jams after a couple print hours.

Cooling fan RPM noted to be about 200 RPM slower than on my other printer. The BNBSX hot fins are very slightly deformed - nothing that should make a huge difference in air flow, but there was still something awry.

Replaced the PTFE tubing in hot end. No effect on jamming.

Clearly somehow heat creep is happening on my Slice Mosquito which is designed to be more resistant to that happening.

Nothing seemed that awry with visual inspection. I could swap out parts to blindly diagnose, but maybe thermal imaging will help.

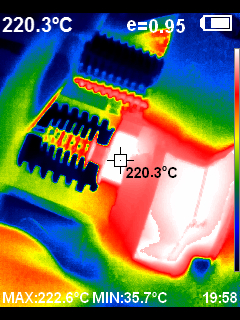

Temperature at the Magnum insulator 220C with heat block at 250C. Those seem correctly functioning.

Hmmn, temperature just above the heat break is 117C. That is above PETG glass transition temp (88C). No wonder it is having heat creep jamps.

1. Heat break thermal conductivity should not have changed much with usage. I don't know of stainless steel becoming more thermal conductive.

2. Temperature of heater block is regulated and measures appropriately. It's not the heat block being hotter.

Therefore, something is reducing cooling of the hot end and allowing temp above heat break to go too high.

Fan? It's a two year old fan. Its RPM is 200 lower than other printer. Is the fan getting weak?

Hot fins? Very slight warping - I don't see how that would make this much difference.

Dust coating/oxidation on hot end parts reducing heat transfer?

Debris or objects blocking airflow? Nothing on visual inspection.

--------

Next step will be measuring the old fan's airflow vs a new fan.

RE: Diagnosing New Onset Heat Creep Jams on Slice Magnum

This is interesting. I have the non-Magnum which doesn't have the insulator but has been problem-free.

Just curious, and I know it doesn't make a huge difference, but have you checked your emissivity setting between the different components as they each represent different surface properties?

RE: Diagnosing New Onset Heat Creep Jams on Slice Magnum

I have no idea what the insulator material is composed. No emissivity adjustments were made. These are just same setting. What will doable is re-measurement of just above heat break after I get fan tested/replaced and hot fins refreshed with new ones.

I have asked Slice if there is are known long term changes in heat conduction of heatbreak or in transfer of heat to air from cooling fins. The latter was piqued by their adding a "coating" to new heat breaks.

RE: Diagnosing New Onset Heat Creep Jams on Slice Magnum

My Magnum was similarly trouble free - until now. 🤔

RE: Diagnosing New Onset Heat Creep Jams on Slice Magnum

Perhaps the coating is nothing more than an improved thermal compound? This could explain "Heat break thermal conductivity should not have changed much with usage." Given that the metals are dissimilar, that could have advanced the degradation of the thermal compound.

If you're feeling froggy maybe disassemble the entire unit, clean all the mating surfaces, reapply high temp thermal compound and give it a go with the new fan. Good luck!

RE: Diagnosing New Onset Heat Creep Jams on Slice Magnum

I'm trying to do this in a stepwise fashion to find the root cause.

Measured fan output velocity on Slice and E3D printers. I will refer to the two printers via their hot end. They are both using identical BNBSX extruders. Both had their extruder fans dismounted from extruder to allow velocity measurement at their output. Fans were activated by setting nozzle temperature to 70C.

Flowmeter was not corrected for plenum size. So, these velocity results are useful relative to each other, but not absolute velocities.

Slice printer's extruder fan velocity 0.98 m/s <--- this is the misbehaving printer

E3D printer's extruder fan velocity 1.05 m/s <-- this is the printer that is not jamming.

Not a huge difference in fan outputs. Only 7% lower on the Slice printer's fan. It is indeed lower, but was my printer so close to hot end cooling failure that a mere 7% drop in fan output would cause heat creep? 7% seems more likely to be within unit to unit variance in fans.

Next, I will swap out the hot fins and see if that makes a difference.

RE: Diagnosing New Onset Heat Creep Jams on Slice Magnum

I think some progress, but still some questions remain.

Measured two more, fresh Noctua NFA4x10 fans (one black , one beige) with regulated 5 volt supply voltage

A. measured 0.98 LPM

B. measured 0.98 LPM

Both are identical to the rate measured on my Slice Printer's fan. This further confirms that drop in extruder fan power is not the root issue.

Other findings...

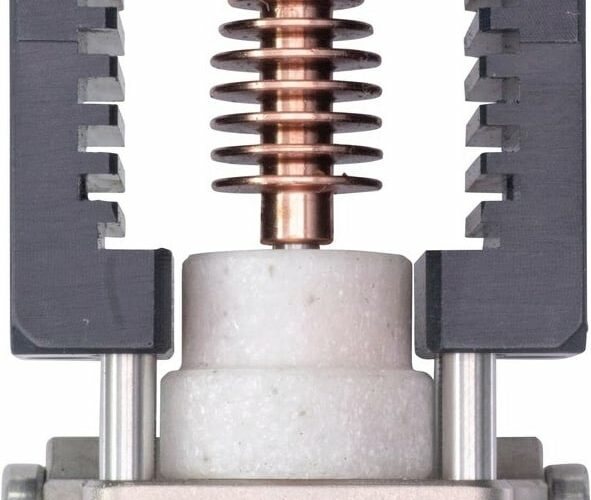

Very bottom segment of copper portion of Mosquito heat break was coated with a fine layer of white, plastic off gassing material. This may very slightly reduce heat transfer to air, but probably not by much. Contaminant was easily removed with a q-tip and brush.

Biggest find is that set screw for my big gear which drives the BNBSX shaft was slightly loose. This let the extruder motor sometimes move without moving the drive shaft properly. I think this is the likely root cause of the new problem.

While I had machine apart, I also altered the hot fins to move airflow up slightly to better match the Magnum's heat break position. The hot fins for a regular slice allow some airflow directly at the magnum's insulator. This should increase airflow at the copper cooling fins.

I agree with the concerns regarding emissivity. The copper cooling fins seem to radiate more efficiently that the stainless steel tubing. Although, the temperature was 112 via thermal at the copper fin, the stainless tube always reads lower, when in reality it should be hotter.

Switched to a mini-bead direct contact temperature probe and got

Bottom copper fin : 62C

Top of copper barrel (the one just under bottom copper fine): 67C

Bottom of copper barrel (the one just under bottom copper fine): 107C

Top of extended Magnum chamber: 130C

Heat block at nozzle attachment: 242C

There is a very steep temperature gradient between top and bottom of the copper barrel. That is the Slice's heat break region.

For comparison, the E3D V6 measures 75C at top of its heat break. The Slices is reading 67 at the top of its heat break. So, the Slice is definitely keeping top of heat break cooler.

Unfortunately, I don't have measurements with direct contact before altering the hot fins to optimize Magnum airflow.

New STL's for the altered magnum optimized hot fins have been added to my BNBSX Mosquito Kit on Thingiverse.

Bottom lines for this adventure:

Probably was caused by set screw working loose on my large BNBSX drive gear after a year of printing. Note, I'm not talking about the Bondtech drive gears, but looseness there would also cause similar grief.

Gave me a chance to optimize airflow fins for Slice Magnum rather than using same airflow as regular Mosquito.

Still need to do more long prints to verify the issue has truly been solved.

RE: Diagnosing New Onset Heat Creep Jams on Slice Magnum

BTW, I also had a Sunon MF40100V1-1000C G99 fan and grabbed an airflow measurement from it while testing the two new Noctua fans.

Sunon measured 1.95 MPS - almost double what the Noctuas deliver. It is, of course, definitely louder than the Noctuas.

(Just noticed I had put LPM on the new Noctuas, but I can't edit the error)

RE: Diagnosing New Onset Heat Creep Jams on Slice Magnum

Hopefully, the set screw was the root cause. Nothing worse than when you believe you corrected the problem to only later discover you stumbled across a contributor but not the root. It is funny though as I too have noticed, and cleaned, a thin white film deposited in the general area of the heatsink. This made me wonder if the heatsink is affixed to the tube via chemical compound rather then brazing or the sort, and would explain some of the deposits that I have seen as well as the drop in thermal conductivity that you may have seen. Worth keeping an eye on, maybe when approaching tube/heatsink replacement to take measurements before and after to compare.

Side note on the emissivity - if you can affix small swatches of black electrical tape at desired measuring points, you can set emissivity of 0.95 and obtain relatively accurate readings in one shot across different surfaces/types.

RE: Diagnosing New Onset Heat Creep Jams on Slice Magnum

Thanks for the tip on electrical tape. Does that work for silicone fusion tape as well?

Some of the surfaces are a bit hot for electrical tape.

I have my finger crossed. It won't be until at least 24 hours of solid printing before I will feel confident again with the printer. If it still thermal jams, I'm putting in the Sunon fan. Worst was when it jammed, and then unjammed itself some time later. Made a nice sphagetti monster. Thankfully, not a blob of doom.

RE: Diagnosing New Onset Heat Creep Jams on Slice Magnum

I'm not sure about the silicone fusion tape, but you could just place a piece on a known (temp block) and derive an emissivity for use. If you're using something like FLIR desktop software you can then pick out multiple temps in one shot that is reasonably accurate.

RE: Diagnosing New Onset Heat Creep Jams on Slice Magnum

place a piece on a known (temp block) and derive an emissivity for use

Another great tip. I've only been using mine to find hot spots on circuit boards.

RE: Diagnosing New Onset Heat Creep Jams on Slice Magnum

I am getting severe heat creeps on my Mosquito Magnum as well. I am using a Bondtech Extruder as well. I am trying to talk to Slice Engg to see how this can be fixed, or if they can swap out my magnum to the original mosquito's. I am still under the 1 month return policy. My Sunon MF40100V1-1000C G99 fan is yet to arrive, probably tomorrow. I will replace the noctua to see if it fixes the issue.

Were you able to figure out why this is happening? and how to resolve it?

RE: Diagnosing New Onset Heat Creep Jams on Slice Magnum

You can use charcoal or black graphite as the emissivity spot, used to do this on stainless steel steam traps to monitor their temperature.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: Diagnosing New Onset Heat Creep Jams on Slice Magnum

@chocki

Dont understand that. Can you explain a bit more, or maybe a picture ?

RE: Diagnosing New Onset Heat Creep Jams on Slice Magnum

You basically rub the charcoal (if it will adhere) or graphite (Black rather than grey) onto the part you are trying to measure the temperature of, this causes the graphite to heat up to the same temperature as the part you are measuring, and being it is black, it is easier for an IR thermometer to read accurately.

It also makes it easy to read the same spot each time so there will be less variance in temperature (or at least should be if all is OK).

An 8B pencil should work, but very smooth surfaces may require scraping some of the graphite to form a powder or use charcoal dust, then mixing it with a drop of water based adhesive and paint this onto the surface, the water will evaporate leaving the graphite stuck to the smooth surface. It also simply wipes off with a damp cloth afterwards if you ever want to remove it.

This black spot is better for emissivity than shiny metal, and does not melt like PVC tape would.

The blacker the

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: Diagnosing New Onset Heat Creep Jams on Slice Magnum

So far so good after fixing loose main reduction gear and redirecting air upward toward Magnum's higher heat break fins. The ill Slice Magnum BNBSX is now 11 hours into a PolyMax Polycarb print of spare parts for itself.

I'm fairly confident that the heat break is now working properly given the large differential temperature measured via contact probe. The top of heat break is cooler than on my E3D V6's heat break.

I think the erratic filament due to the loose reduction gear caused incorrect filament motions that eventually caused the thermal jam. Having a less efficient airflow pattern was also reducing the heat break cooling fin effectiveness. The combo fix seems to have helped.

Nozzle temp is 290C / Bed temp 110C / Print fan only for bridging / Phenolic print surface coated with Elmer's Ultra slurry.

However, PC is higher temp material and heat creep jams are more likely the lower the filament melt point. I'll have to do some long PETG prints after finishing the PC spares.

I really hate swapping between the materials because going back down to PETG from PC requires a full hot end cleaning to remove all higher temp material residue before printing with lower temp. So, once i'm in PC, I get all my PC prints done before switching back down.

RE: Diagnosing New Onset Heat Creep Jams on Slice Magnum

Blimey Guy, when do you sleep?, with your recent work load (My hat goes off to you BTW) and printing, and fixing your printer, I just don't know how you do it.

BTW I went through your 0.9 Deg firmware and pinched all the bits to modify the latest 3.9.0 firmware for my printer and it works but there seems to be a bug in the latest firmware for the belt test results. Everything passes, but the firmware says self test failed!, yet there is nothing apparently wrong. Any pointer where I should be looking for the self test belts code.

Thanks.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: Diagnosing New Onset Heat Creep Jams on Slice Magnum

I have not had a chance to read through the 3.9.0 source code. So, yes stretched a little thin and I have not wanted to lose a printer or both while needing to work on BunnyPAPR.

I do have a question which I hope you don't find too far beneath your user level. Did you factory reset and clear all data when moving to the new firmware?

I'm wondering because passing through initial setup, but failing self test might also suggest old stored data that isnt' being cleared. Prusa's prior firmware behavior for clearing out old values was always odd. I doubt that has been much improved in 3.9.0.