Bondtech extruder upgrade - results (re:inconsistent extrusion #602) , review and issues

I'll come right out and post the results first: the classic 602 "basket weave" inconsistencies are gone (for me)

...I was staggered to see these results but this pic speaks for itself. (left is bondtech obviously, right is mostly stock) Now to be fair there are a lot of other things wrong with the older print, they're not the same brand of pla, and it was done without many of the other mods we've come up with since.

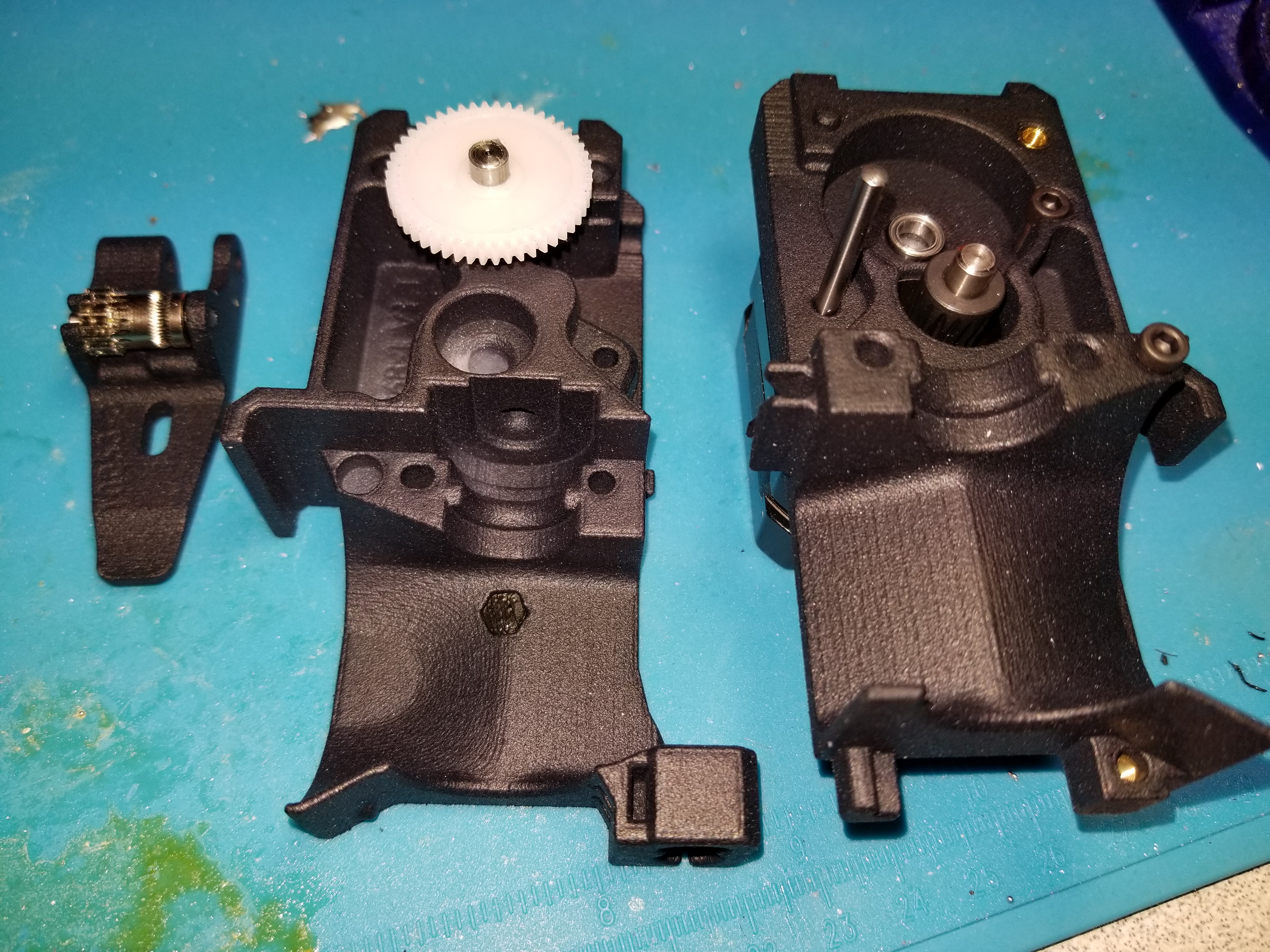

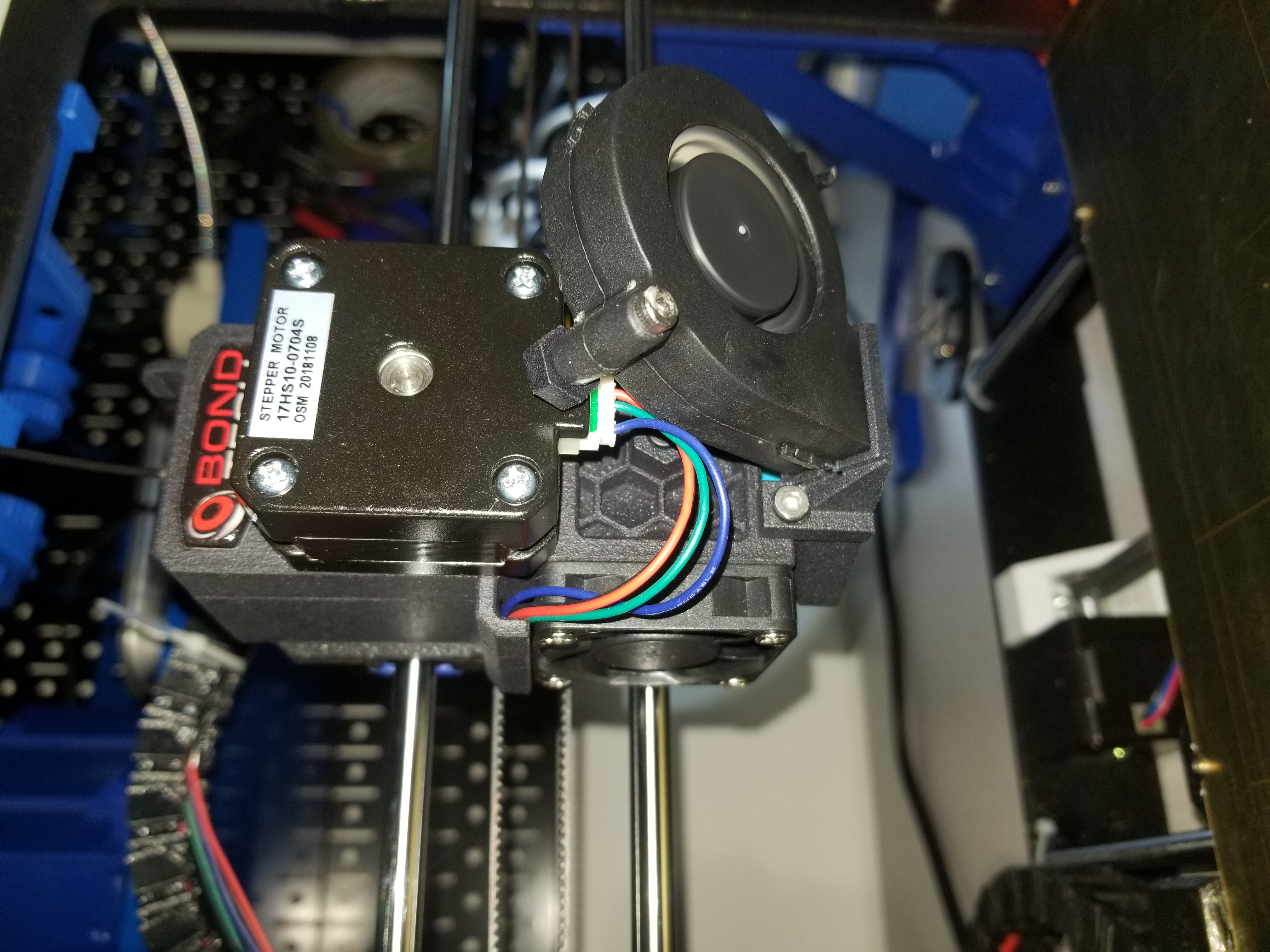

The extruder itself is gorgeous and the quality is essentially perfect (printed in SLS nylon)

I ordered the mk2/s version, which is actually the exact same parts plus a new set of gears for 10$ more. I printed the Bear carriage+backplates in 3dxtech glass-fiber filled petg.

All hardware and fasteners are included, no need to go digging square nuts out of your old extruder. Molex adapter for the motor and a new 45 degree fan shroud also included. Instructions are sufficient but if you've built the kit then you'll be fine.

Fun fact: the entire assembly weighs less than the stock motor alone

Issues:

-High speed retracts on this stepper are noisy. If this bothers you (it does for me) then 25 mms is about your limit to keep things nice and silent.

-Linear advance does not play nice with this stepper. You'll notice some serious clicking from the acceleration with any K value. Either disable it (M900 K0) or switch to Klipper (credit: discord user Knoopx). I'm not sure if this affects the performance in any way, but it annoys me enough to disable it.

-Non-standard ptfe lengths are needed, print out their cutting jig before you start assembly

-This design improves airflow significantly, but the sunon fan upgrade is still recommended

Verdict: buy it now.

https://www.bondtech.se/en/product/prusa-i3-mk2-5-mk3-extruder-upgrade/

Re: Bondtech extruder upgrade - results (re:inconsistent extrusion #602) , review and issues

Hi Curtis,

Thanks for sharing your experience. 25 mm/s max speed would be a no-go for me.

Your black cat looks over extruded. White cat was sliced differently (you can see it on the seam), is using different color/filament and most likely was printed with different speed settings. Comparing this prints is kind of not possible.

I'm glad you found the right settings and right upgrade for you. And I know there is another magic motor/extruder/printer part which solve "#602 issue TM". This is how third party manufacturer making money. 😉

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Bondtech extruder upgrade - results (re:inconsistent extrusion #602) , review and issues

I guess the biggie for me is the angled blower, I just can't bring myself to mount my blower off axis. That and I think I've spent enough on the MK3, my next upgrade will be the Railcore kit for sure as it's supposedly going to be compatible with the E3D tool-changer which I desperately want.

Re: Bondtech extruder upgrade - results (re:inconsistent extrusion #602) , review and issues

Hi Curtis,

Your black cat looks over extruded.

that has nothing at all to do with 602. I'm not comparing anything else.

25 mm/s max speed would be a no-go for me.

retracts, not max speed. i run them at 45 normally but haven't noticed any detrimental effect so far.

Re: Bondtech extruder upgrade - results (re:inconsistent extrusion #602) , review and issues

that has nothing at all to do with 602. I'm not comparing anything else.

This is exactly my point. I miss a one to one comparison. Same gcode, same filament. Original extruder vs bondtech.

retracts, not max speed. i run them at 45 normally but haven't noticed any detrimental effect so far.

Sorry missed that. My default is 35 mm/s. Faster is usually better, with 25 you might get heat creep but bondtech has better cooling, so maybe it leverage itself.

Just in case someone gets an impression the white cat is the usual result you will get with the original extruder.

Here is my print from unmodified MK3:

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Bondtech extruder upgrade - results (re:inconsistent extrusion #602) , review and issues

that has nothing at all to do with 602. I'm not comparing anything else.

This is exactly my point. I miss a one to one comparison. Same gcode, same filament. Original extruder vs bondtech.

If being 1 or 2% over-extruded and changing a seam position was all it took to either cause or completely eliminate 602 then we wouldn't be here now. CRTs video series is as scientific as you could reasonably get here and people still complained :/

These are my own results using imperfect models with many modifications and variables being introduced in the interim, all of which I acknowledge in the first post.

Re: Bondtech extruder upgrade - results (re:inconsistent extrusion #602) , review and issues

Slightly off topic - I would like to link this thread here:

https://shop.prusa3d.com/forum/assembly-and-first-prints-troubleshooting-f62/planar-parallel-and-square-t26978-s20.html

guy.k2 documented really good his journey on adjusting his printer. I'm always fascinated how changing only couple angles (we are not talking about replacing parts) affects the print quality in very strange way.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram