RE: Beer Can mod for Prusa MK3/S/+

@karl-herbert

holy mackerel, That is early in the morning.

--------------------

Chuck H

3D Printer Review Blog

RE: Beer Can mod for Prusa MK3/S/+

@antipode

Perhaps I do not understand the unit specification correctly. One micrometer = 0.001mm (1×10-6 metre). BL Touch with 5 micrometer (0.005mm) I can imagine, but PINDA with 0.2 micrometer (0.0002mm) rather not.

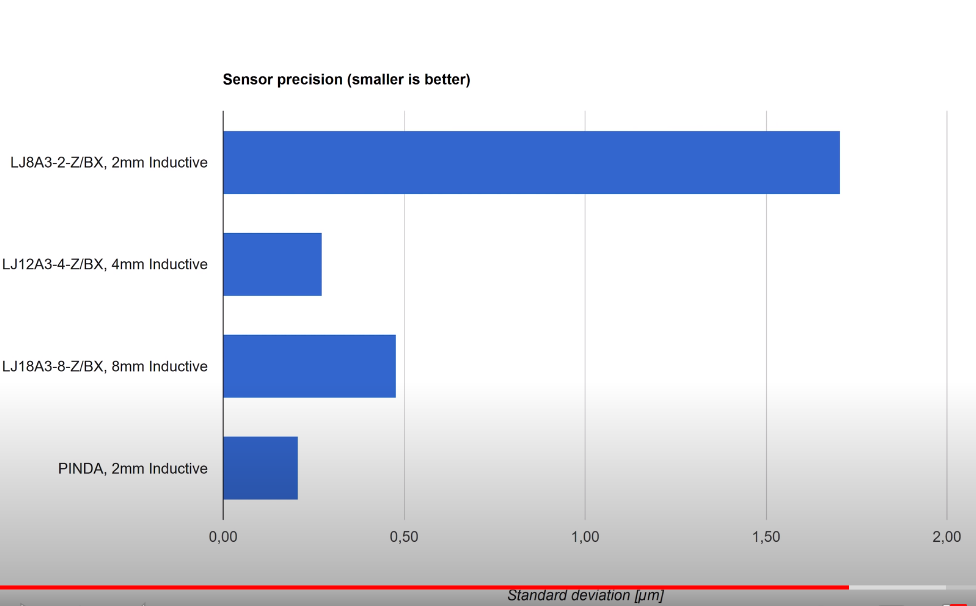

Okay, I just spent 30 minutes trying to find repeatability data for PINDA or any comparable inductive sensor, and I failed. Technical documents I found list all electrical and mechanical characteristics, but nothing related to accuracy. Can anyone provide official specs for the PINDA probe? So far the only thing I have to go by is the measurements from Thomas Sanladerer's video, claiming that all inductive sensors he measured achieved sub-micron repeatability. His measurement for BLTouch was spot on, by the way, he measured between 3 and 6 micron repeatability for it in the same video.

Anecdotally, if a fully plastic mechanical/electrical device can achieve 5 micron accuracy, I can definitely believe that a purely inductive device can achieve accuracy less than 1 micron, but, of course, that's just my opinion.

Isn't this what you're after?

It's from the same video that you referenced. Under Tom's test conditions (which are different from actual in-use conditions over a heated bed), Tom found a 0.2micron standard deviation for Pinda v1. Reportedly v1 was affected by heat, however. Exactly how, I do not know.

Is it true that v2 is free of that issue?

RE: Beer Can mod for Prusa MK3/S/+

I don't know that these repeatability tests tell the whole story though. Triggering at the same height but at different points needs to figure into it as well. For instance, suppose the PINDA triggers at a height of 2mm near the edge of a build plate with a repeatability of 0.2microns in that location but triggers at a height of 4mm in the center of the plate, also with a repeatability of 0.2microns. If that were true (and I don't know that it is, as I am only making up these numbers to illustrate a possible issue), then that would be pretty lousy compared to, say, a BLTouch, or whatever, where it shouldn't matter whether or not it's near the edge or not.

Perhaps as a practical matter this possible "issue" is worked around by not getting too near the edges, so maybe it's no big deal. Maybe. I just don't know.

RE: Beer Can mod for Prusa MK3/S/+

Dang. My edit time expired. I was going to add that since the build plate isn't a completely uniform temperature, then any temperature sensitivity would throw off the uniformity of height measurements, as different measurement points might have different temperatures. I'm guessing this was the nature of the problem for Pinda v1?

RE: Beer Can mod for Prusa MK3/S/+

I have rummaged around a bit in the technical literature. Industrial sensors usually have a repeat accuracy between 0.005 and 0.015mm. Events such as temperature fluctuations and electromagnetic interference can scatter the values.

So I assume that the PINDA at 23 degrees C. is constant at approx. 0.005mm and increases depending on external influences up to 0.03mm. It is also important to know the values of the hysteresis, which, as far as I know, are taken into account by Prusa in the firmware.

Anyway. The PINDA V2 is sufficient for leveling the MK3 print bed, since you also have the option of gradually compensating for the temperature fluctuations in the firmware table. When leveling, I also always switch off the print bed briefly to exclude electromagnetic interference as far as possible.

More accurate always works. the question is - what does it improve?

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Beer Can mod for Prusa MK3/S/+

Thanks, everybody! I learned a lot on this thread.

RE: Beer Can mod for Prusa MK3/S/+

@karl-herbert

Bingo!. Great points. I have learned a lot from the thread also. Thanks for the discussion.

--------------------

Chuck H

3D Printer Review Blog

RE: Beer Can mod for Prusa MK3/S/+

There's a lengthy discussion of the effects on heat on the PINDA v1 in stahlfabrik's wiki post that I used as the basis for developing my 2-step PINDA warmup start gcode. In short, having the PINDA v1 at a consistent temperature (~35C) yielded better MBL results. The 2-step routine hovered the PINDA above a heated bet until the temp hit 35C before bed leveling. While this wasn't strictly necessary for later PINDA versions, having the entire printer warmed up consistently helped overall, so I've kept the routine. Unfortunately, SuperPINDA breaks M860, so I've had to adjust the code.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Beer Can mod for Prusa MK3/S/+

The original question was whether PINDA was accurate enough to achieve the bed alignment goal of 0.1 mm variance across the bed, and, from all the information we've seen so far, it seems that PINDA is somewhere between 0.005 and 0.0002 mm accurate. Regardless of the actual PINDA accuracy, it's quite clear that it's accurate enough to support the 0.1 mm variance goal of the beer can mod.

RE: Beer Can mod for Prusa MK3/S/+

@antipode

It is an interesting project. I am watching curiously to find if there is a need.

--------------------

Chuck H

3D Printer Review Blog

RE: Beer Can mod for Prusa MK3/S/+

@cwbullet

Since I do not drink beer, I decided to install steel springs. But what is not, can still become 😋

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Beer Can mod for Prusa MK3/S/+

@karl-herbert

How is it working out?

--------------------

Chuck H

3D Printer Review Blog

RE: Beer Can mod for Prusa MK3/S/+

@cwbullet

Since I do not drink beer, I decided to install steel springs. But what is not, can still become 😋

Oddly, I don't drink beer anymore, too, I nicked the empty beer can from a party. In any case, where I live any recycling bin has a beer or a soda can for the taking.

Curious how often you'd need to readjust the bed with springs.

RE: Beer Can mod for Prusa MK3/S/+

I quit drinking beer years ago. I would have to borrow some from the local bar.

--------------------

Chuck H

3D Printer Review Blog

RE: Beer Can mod for Prusa MK3/S/+

@cwbullet

I use hardened steel springs from a local manufacturer from whom I purchase springs for over 30 years.

They have always performed well. I have replaced the aluminum spacer sleeves with these springs on all my printers. I have leveled the print bed once and check this occasionally. So far, I have not been able to detect more than 0.02 to 0.05mm deviations. The readjustment takes only a few minutes. The printing bed springs are replaced every 2 years (once so far).

https://www.gutekunst-formfedern.de/en/

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Beer Can mod for Prusa MK3/S/+

@antipode

Is of course a good idea! I always use carbon steel foils in various thicknesses (0.03 - 1mm) to underlay for such purposes.

https://metallstore24.de/kohlenstoffstahl-bleche-25x300mm

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Beer Can mod for Prusa MK3/S/+

@karl-herbert

Those would work very well. I will have to see if they are avilable in the US if I decide to endevour down this route.

--------------------

Chuck H

3D Printer Review Blog

RE: Beer Can mod for Prusa MK3/S/+

@antipode

Is of course a good idea! I always use carbon steel foils in various thicknesses (0.03 - 1mm) to underlay for such purposes.

https://metallstore24.de/kohlenstoffstahl-bleche-25x300mm

Steel shims may be challenging to get past the numerous magnets in the bed. I'd choose brass or Aluminum for this reason.

RE: Beer Can mod for Prusa MK3/S/+

@karl-herbert

Those would work very well. I will have to see if they are avilable in the US if I decide to endevour down this route.

Lee Valley sells a set of 6 brass shimming sheets of various thicknesses, very handy to have for projects.

RE: Beer Can mod for Prusa MK3/S/+

@antipode

The foils are also available in animagnetic and stainless steel versions. But of course you can also use aluminum, brass or the like. I mainly use the thin foils for Z-probing on my milling machine, less on the printer.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.