Adaptable enclosure for a Prusa MK3

I started designing an enclosure and after having bought the Polycarbonate and some clear edge connectors, I decided why not print all the edges. (Anyone want some 18ft clear edges?) Having gone down that path a while I then said why don't I just buy the damn thing. I saw some off the shelf units I liked for less money and one hell of a lot less work, but I'm not one to abandon a project once I've committed to it, so I continued on and here is the outcome.

It's an expansion of the original ideas I had making a "bathtub" for around my 3D mill to keep the cuttings contained. I've always liked piano hinges and how adaptable they made things so I carried that through to this design as well. I didn't want to make any decisions on exactly how I would be using it so I made it as adaptable as I could. I'm pretty happy with the outcome but I would never recommend anyone else spend the time or money doing it that I just did, lol.

Rick

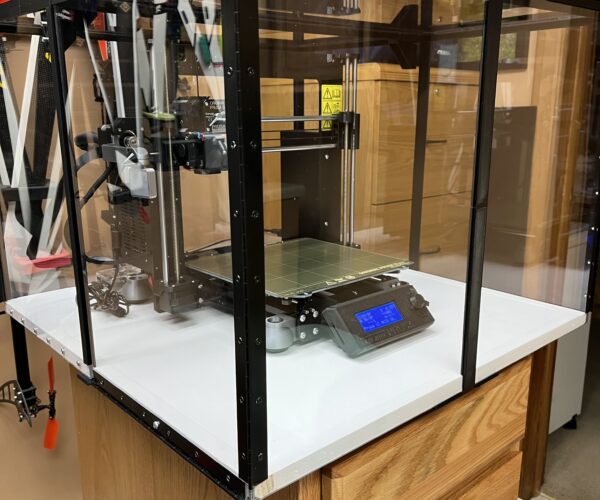

Just front doors open (How I use it for PLA)

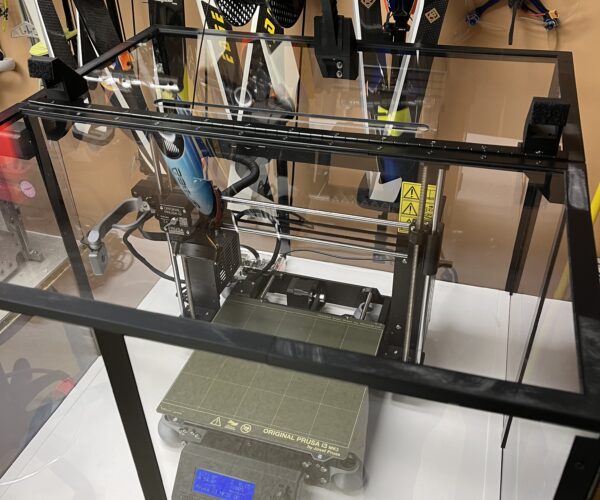

Fully Closed

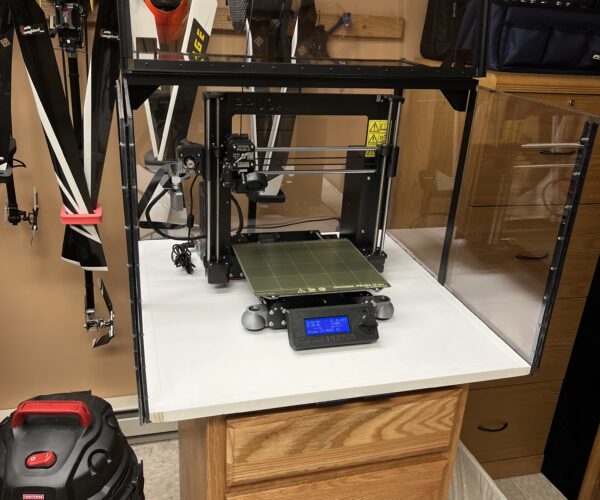

Doors open, Top up.

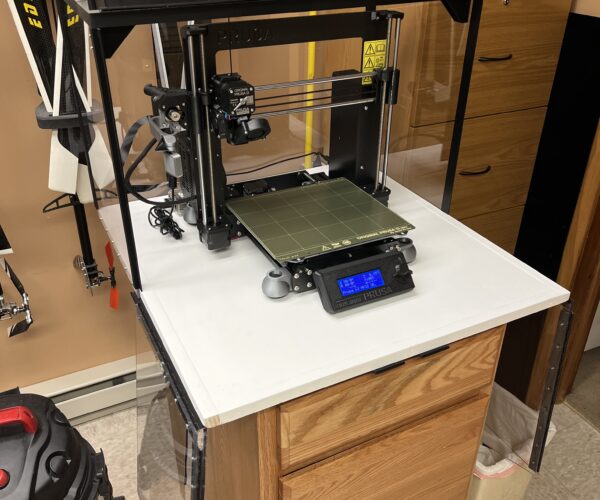

Fully open, top up and sides down.

RE: Adaptable enclosure for a Prusa MK3

Very well thought out and good looking!

A person who never failed never tried anything new. -Einstein

RE:

Now that looks a lot nicer than any commercial option I've looked at. One thing that always bugged me about the commercial enclosures is that none appear to have folding doors. The best modification I've made to my Lack enclosures was to add sliding doors that disappear when open and are not in the way. Your solution looks even better! Would love for you to somewhere, somehow publish a parts list and assembly instructions.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE:

Thanks, glad you like it! I'll consider making it repeatable but it kind of evolved as I went. I cut the poly to size as needed and I grinded some edges to fit and I didn't record exact sizes. I have a bit of sag in the top panels as the 1/8" polycarb flexes a bit more than I anticipated and I was limited as to how long I could make the edge pieces by my printer max. The hinge and supports stiffen up the back top panel, but the front top panel sags just a bit. It doesn't hurt anything and it actually helps to the front doors to stay shut, but it's not quite as perfect as I intended. I've been tempted to add a metal stiffener bar just behind the front edge, but since it has worked so well I have not bothered.