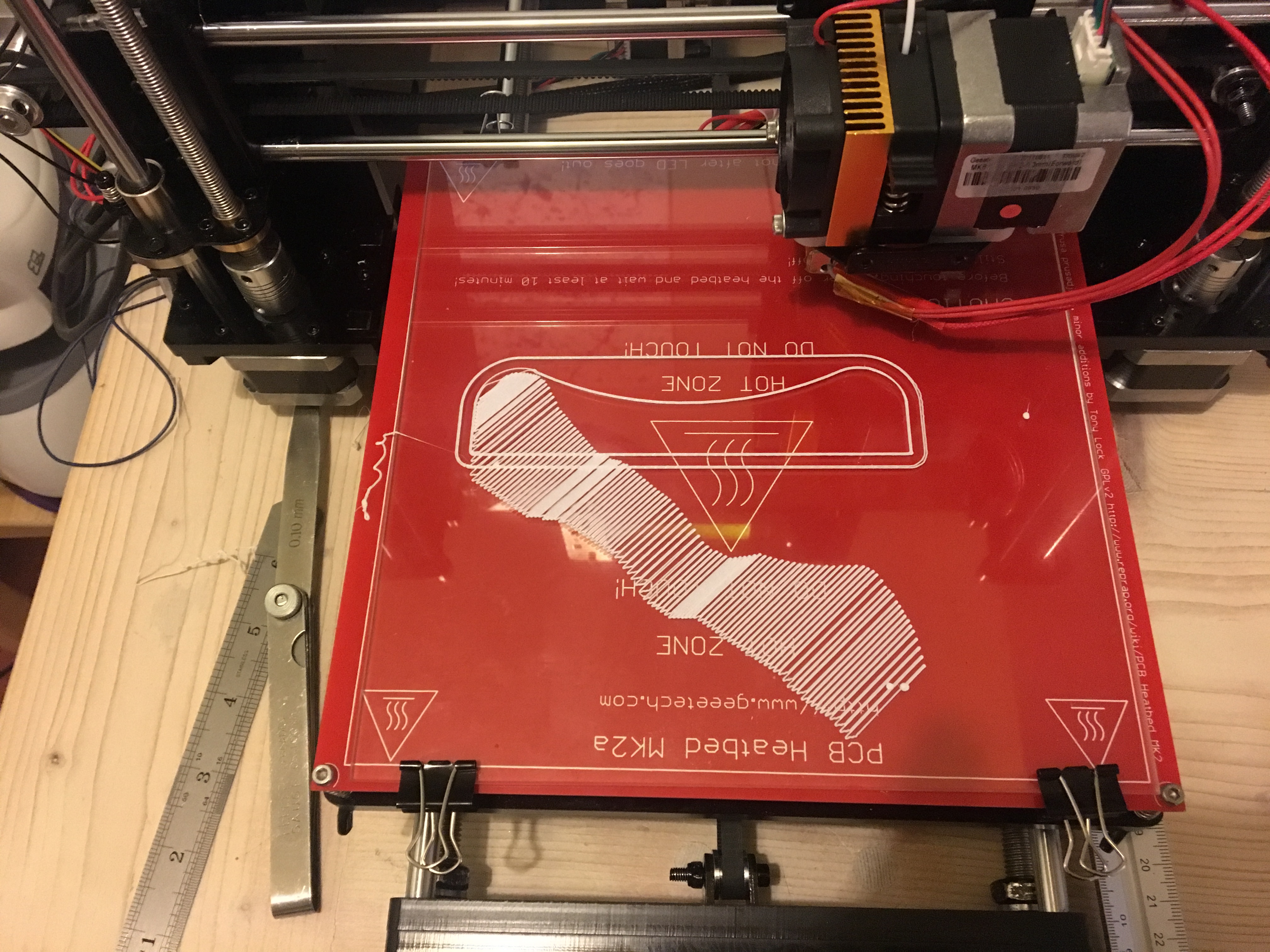

Y axis getting worse across print

Please see the image attached, I have no idea what’s causing this - I’ve been tightening and un-tightening each of the belts, updated the firmware, bought a Digital Caliper to make sure the x axis rods were perfectly horizontal and it all just seems to be getting worse.

Any ideas? I’m losing the will to try with this printer now...

Re: Y axis getting worse across print

I'm not sure I'm qualified to answer this, but since nobody else has, I'll give it a try.

An observation: When the direction changes to northeast, the Y doesn't start moving immediately.

It could be five things:

1. Your slicer software is psycho.

2. The Y belt is jumping.

3. The pulley is slipping.

4. The platform is binding.

5. The motor is flaking out.

I'm going to rule out #1 for now.

If the Y belt was jumping, each of those skips would be one or two belt teeth long. It doesn't look like that's the case, but if it is, make sure the Y belt is tight enough. When you twang it, it should give you a mid-range note (about middle C). If it's higher than that it may be too tight. If it sounds like a string base, it's too loose. Judging from what you said, it's probably not too loose. If the idler pulley or the drive pulley is too far out of line with the block on the bed frame, that could make it jump, but I think that's unlikely because it would get worse at one end or the other of the Y range.

I can't thing of how exactly the platform binding would cause the particular problem your having, but it's easy to check. With the belt off, it should move with not much force. If it binds, make sure the Y rods are parallel. Make sure they're not skewed (i.e., the base of the printer is not sitting entirely flat). Make sure none of the slide bearings are crooked. Make sure you don't have a bad bearing.

Finally, the motor flaking out fits what it's doing. When Y changes direction it needs more force than to keep going the same direction. Not enough force could be caused by the drivers on the control board not doing their job. The power supply might be wimpy. If it works better when the bed is cold, blame the power supply. If it's the control board or power supply, you might have the wrong one. It's possible a bad connection or a plug not quite in could be creating resistance that keeps the system from delivering the power the motor needs. I suppose it could be the motor itself, although I can't figure out what would make the motor mostly work but not always. If you've tried everything else, see if swapping motors does any good.

Re: Y axis getting worse across print

I forgot about the drive pulley. Make sure one of the setscrews is tightened against the flat part of the shaft.