Random X-axis jump

I posted earlier that I have "only" had X-axis belt tension issues before and otherwise only the usual silly models etc.

Over the last 3 days I have been struggling with a new problem. I need help.

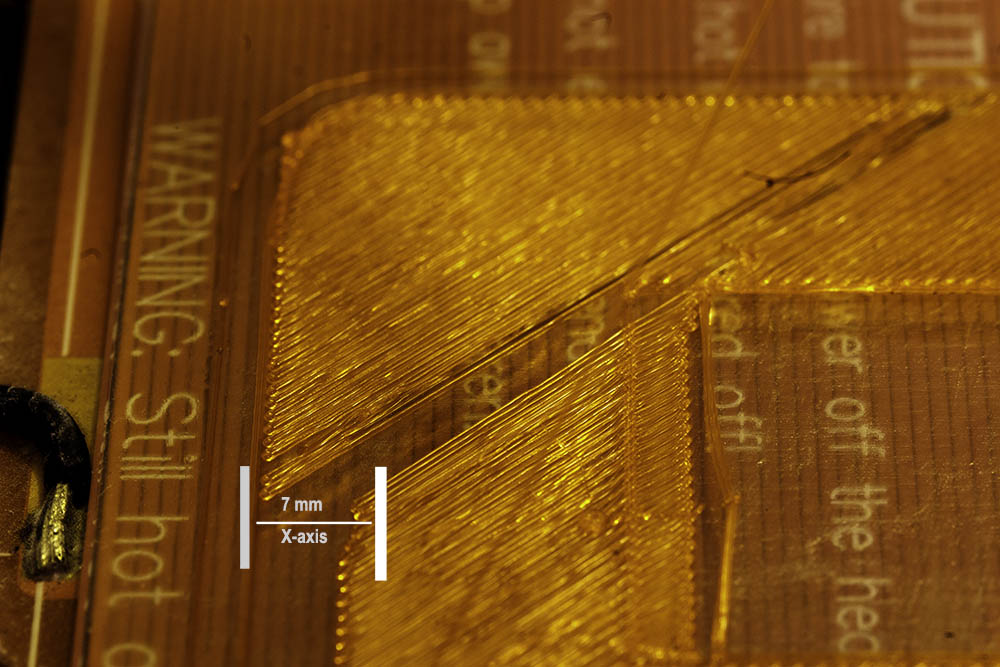

This image is a small version of the phenomenon. (I have been experiencing. I have a 6 hour print where the lateral X slide is measurable in cm)

It represents a random X-axis jump to the left. On some models it is a huge jump and only after 3 hours!

In this case it is the first layer which is why I chose this example.

As you can see, part way through the layer, the X-axis stutters and re-aligns some distance to the right. In this case- 6 to 7 mm.

I have watched it for hours and when it happens it is like the X motor slips but I can't actually see what is happening.

Here's what I looked at and tried:

1) Tightened the X belt.

2)Fixed the LH Z support rod. It wasn't seated properly.

3) Dismantled and cleaned all the extrusion.

4) re-calibrated the plate clearances and all the end stops.

5) Tried old models, know to work.

6) Change material and PLA to ABS.

7)

I mention all this to narrow down potential issues. I should also state that up this this point I have managed dozens of prints successfully and know of nothing that I have changed before this manifest itself.

Ideas?

Bob

Re: Random X-axis jump

Hi Bob.

Did you also tried to tighten pulley on motor on x-axis ? One of the screws has to be tighten on flat side and the other on round side . make sure they are really tight. Does your carriage slide easily ?

Re: Random X-axis jump

Yes I took it apart and checked the flat and the screw and re-assembled it. It had no effect. The suggestion was welcome all the same. I may have missed something.

Bob

Re: Random X-axis jump

Hi

I had the same issue - see this thread: http://shop.prusa3d.com/forum/prusa-i3-kit-building-calibrating-first-print-main-f6/y-axis-issue--t405.html

If the cause is the same, it was fixed by increasing the XY motor current in the firmware.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Random X-axis jump

I was on the road for 2 weeks so couldn't try anything or reply.

I considered what I had changed and went back and re-attached the belts and re-calibrated the end stops and generally checked things out.

I still have exactly the same issue on any print I try - random X shift to the right of a few millimeters.

I read the lengthy dissertation on stepper motors, PWMs and current limitation on the Y-axis thread and my issue may be motor current.

If it is I don't understand why anything has changed. I was too lazy to do the upgrade to make it quieter so I am on the same version of software I have always had.

I am loath to add another variable into the equation by updating the firmware until I know what's causing the problem,

I am no further forward. The quality of the printing between jumps ( 10 layers in perhaps) is great. Everything looks aligned and running well until it skips.

Any other ideas folks?

cheers

Bob

Re: Random X-axis jump

Hi Bob

There are various firmware versions available to download; I would suggest that the next step is to try a different firmware version as you can always revert to your current firmware.

My current thought however, is that there may be a cable issue. If the X axis motor cable has one wire which has broken inside the plastic sheath then it is very possible that movement of the cable occasionally break the connection and the motor does not turn as expected. You may be able to check for this with a multimeter across the motor connector and physically moving the wires.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Random X-axis jump

With the cable issue in mind I thought I would try to locate the origin of the problem a different way. I checked by moving the X axis using the manual commands. Moving it back and forth to see if it would skip. It didn't, but I noticed the X microswitch was doing nothing. I adjusted it and reset the offsets.

I launched a print.

After only a few layers it skipped. What I noticed when I stopped the job and moved the axis again was that the X axis where X=0 was now thought to be 4mm to the right of where it had been. My reasoning was that the machine believes that he X axis is in a different place (that is the definition of shift) and that was most likely to happen by over shooting the X=0 or not getting back to X=0.

The image shows the shift again and according to the display this nozzle is at X=0 but it is 4 mm right of the original home position. S=4mm by the way.

When I select "Auto Home" and then go to move the X axis the value starts at -4. I move right manually and it won't go back below "0" on the way back.

I am feeling pretty confused at this point.

I will keep trying.

Re: Random X-axis jump

With the cable issue in mind I thought I would try to locate the origin of the problem a different way. I checked by moving the X axis using the manual commands. Moving it back and forth to see if it would skip. It didn't, but I noticed the X microswitch was doing nothing. I adjusted it and reset the offsets.

I launched a print.

After only a few layers it skipped. What I noticed when I stopped the job and moved the axis again was that the X axis where X=0 was now thought to be 4mm to the right of where it had been. My reasoning was that the machine believes that he X axis is in a different place (that is the definition of shift) and that was most likely to happen by over shooting the X=0 or not getting back to X=0.

The image shows the shift again and according to the display this nozzle is at X=0 but it is 4 mm right of the original home position. S=4mm by the way.

When I select "Auto Home" and then go to move the X axis the value starts at -4. I move right manually and it won't go back below "0" on the way back.

I am feeling pretty confused at this point.

I will keep trying.

Re: Random X-axis jump

OK Robert, this is getting very strange. I think it's time you contacted support about this. Use the Live Chat on the shop pages and give them a link to this thread. Please ensure that they are aware that you are using older firmware as this will assist them.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Random X-axis jump - RESOLVED

I have been an engineer for 30 years and it's amazing how the solutions to problems are often so obvious that you look for solutions non-engineers might not consider.

It turns out my whole problem was the X axis guide rods were sticking. With the motors disengaged, they slide clumsily but always have. I attributed that to the way the belt and motor worked. Last night I took the belt right off and found that the X motor was catching on the rods pretty randomly.

The solution to the problem was one of simple maintenance of a mechanical machine - lubrication.

There is little posted on line about exactly what is needed and when (at least I found very little) but a little PTFE based machine oil has fixed my printer right up - and, as a bonus , it's quieter.

The 8 hour print that first manifested the problem ran smoothly last night.

So in a corollary to Spock's wisdom "If the solution to the problem is too complicated, maybe you missed something simple". I'm glad I resisted the temptation to dig into firmware and motor currents.

For anyone else who has random jumps, check that your guides slide and the whole machine is properly lubricated.

Thanks to everyone for your suggestions. You may have been assuming I was smarter than I turned out to be.

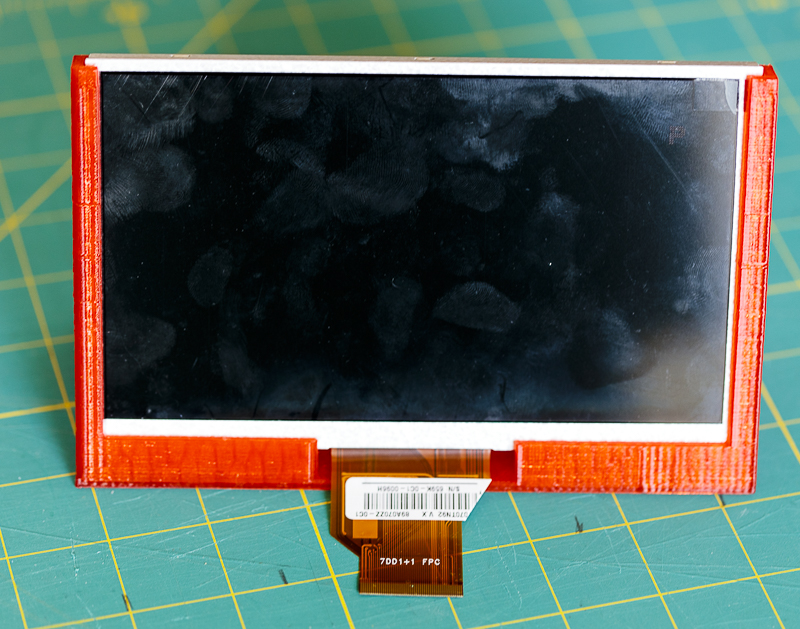

Here's the final print for your perusal. It's a prototype mount for a 7 inch display.

cheers

Bob

attachment=1]BSI_20160131_173A5507.jpg[/attachment]

Re: Random X-axis jump

Very glad you got it figured out.

Happy printing.

Re: Random X-axis jump

Yeah, ditto.

The need for lubrication though is a debateable topic. Lubricate and you get dist and muck gumming up the works and prematurely wear on the bearings. Don't lube and you have the possibility of stiffness, as Bob has found.

Now if the printer was designed well enough and built well enough, would there be a need for lubrication?

I have never lubricated my Prusa and have never had any part wear out. My Chinese clone, on the other hand, was greased (using a copper grease) from day one and I have replaced so many bearings on that, I have tried to remove as much grease as I possibly can, but it still remains.

So what is the answer? To lube or not to lube?

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Random X-axis jump

Where I used to work in Surface Mount board assembly, we also lubed XY tables and such on the various machines. Spray on a cloth, then wipe the rods with it. You want a film, not a buildup of lubricant.

Is this applicable to our equipment? I think so, but it has to be done properly.

Re: Random X-axis jump

Yes, that's all fine in the right environment, but not is a dusty smoker's basement!

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…