Problems with PLA sticking to the print bed

Hello, I have been working on this issue for the last two days, reading site and such but haven't had much luck. I am new to 3d printers, and this is my very first one. I know this is a lot of stuff, but I wanted to detail the issues I have had and the things I have done so someone can point out if I screwed something up majorly.

I have had my printer (Original Prusa i3 kit) for a few days now, and after I initially got it set up I was able to print some of the items from the SD card ok, once I realized that some were set up for PLA and some for ABS, I found out pretty quickly printing PLA with the ABS temp settings didn't work so well. I did have some issues with calibration, as the bed screws didn't fit in the holes on the y-frame. Following some instructions I found, I drilled those holes out a little to remove the powder coating inside them and the screws fit in fine. It was still a bit off, as when all four were in, the heated bed would sort of hang and pop out sometimes. If I took the glass off, that didn't seem to happen. I thought maybe my tempered glass was warped, but after putting a straight edge across it it seems to be straight. So, I found the bed hold-downs on another thread "calibration is killing me" and was able to get 3 of them to print finally. With those on, the calibration seemed to work fine.

This brings me to the main issue I am having now. I have followed the instructions in the 3d printing handblook on preparing the glass. First, I pulled the glass off the bed and cleaned it with rubbing alcohol as well as I can. Then, with the glass at room temperature, I put a layer of the kores glue stick that was provided down. Next, I spray a layer of the ABS juice (prepared by adding 100ml of Acetone to the provided bottle) and let it dry. Finally, I put the glass back on the bed. I am still having issues with the PLA sticking to the glass reliably. As mentioned before I could only get 3 of the hold downs to come out (printing 4 at a time using slic3r).

I have also tried hairspray, painter's tape, in every case the PLA isn't adhering well. Could it be the PLA that came with it is bad? It was sealed in plastic.

Should I put another layer of the glue on top of the ABS juice? Anyone got any suggestions? This is driving me mad. Thanks for any help anyone can provide.

Re: Problems with PLA sticking to the print bed

For PLA, Kores glue + 50C bed is more than enough. You dont need juice for PLA, its meant for printing ABS. In my experience, 90% of success is in proper distance between nozzle and bed. You have propably nozzle too far from glass (in home position).

Dont worry, you will master it in short time :-).

Re: Problems with PLA sticking to the print bed

Hi Michael,

I just struggled this evening with the same issue, after changing glass and messing with calibrating again. The brim was just perfect but the first layer was not sticking.

What helped me in my case was to drastically reduce the print speed of the first layer, going from 80% by default down to 50 % (In Slic3r, it's in "Print Setting" -> "Speed" -> "Modifiers" -> "First layer Speed")

As told by Roman, do not use ABS Juice for PLA, it's not needed.

I'm like Jon Snow, I know nothing.

Re: Problems with PLA sticking to the print bed

Thank you very much guys, I will clean the glass, reapply just the glue stick and then try the first layer speed reduction. Fingers crossed!

Re: Problems with PLA sticking to the print bed

Well, that's a no go. I cleaned my glass really well, and then applied a coating of the Kores glue to it. I loaded the hold downs back into the Slic3r app and set it to the 0.1 detail profile then made 3 copies of the hold down and arranged them in a square. I made the first layer change to 50% as suggested. I also then went back and re-calibrated it for good measure. I code "auto home" on the printer and checked the spacing with the card. I even lowered it just a little bit since roman.t suggested that I might have too much space. I set it so that I can feel the card moving against the nozzle, but it isn't hard to move it at all. I then repeated at all 4 corners, then moved the nozzle to the center of the bed and tested it there as well as a couple of points about 5 cm away from the center in both directions. I didn't feel a discernible difference.

I loaded the sliced model and it started printing, with a very visibly slower speed on that first layer. On the very first layer of the first hold down, the PLA came loose and it became a mess.

Very, very discouraging. I've spent so much time reading and trying things and to get so little success it's frustrating. I guess I'll just wait until my new PLA (different colors) that I ordered comes in and try that, I don't know if bad PLA can even cause this issue but I am ready to pull my hair out.

Edit: Ah I just realized that forgot to mention that I am using Octoprint to send the gcode file to the printer. I don't know (or see how it can be) if that is significant or not.

Re: Problems with PLA sticking to the print bed

You are propably still too far from the glass. Card is too thick IMHO, try normal office paper, you can always go higher or just try adjusting wheels on corners till pla sticks.

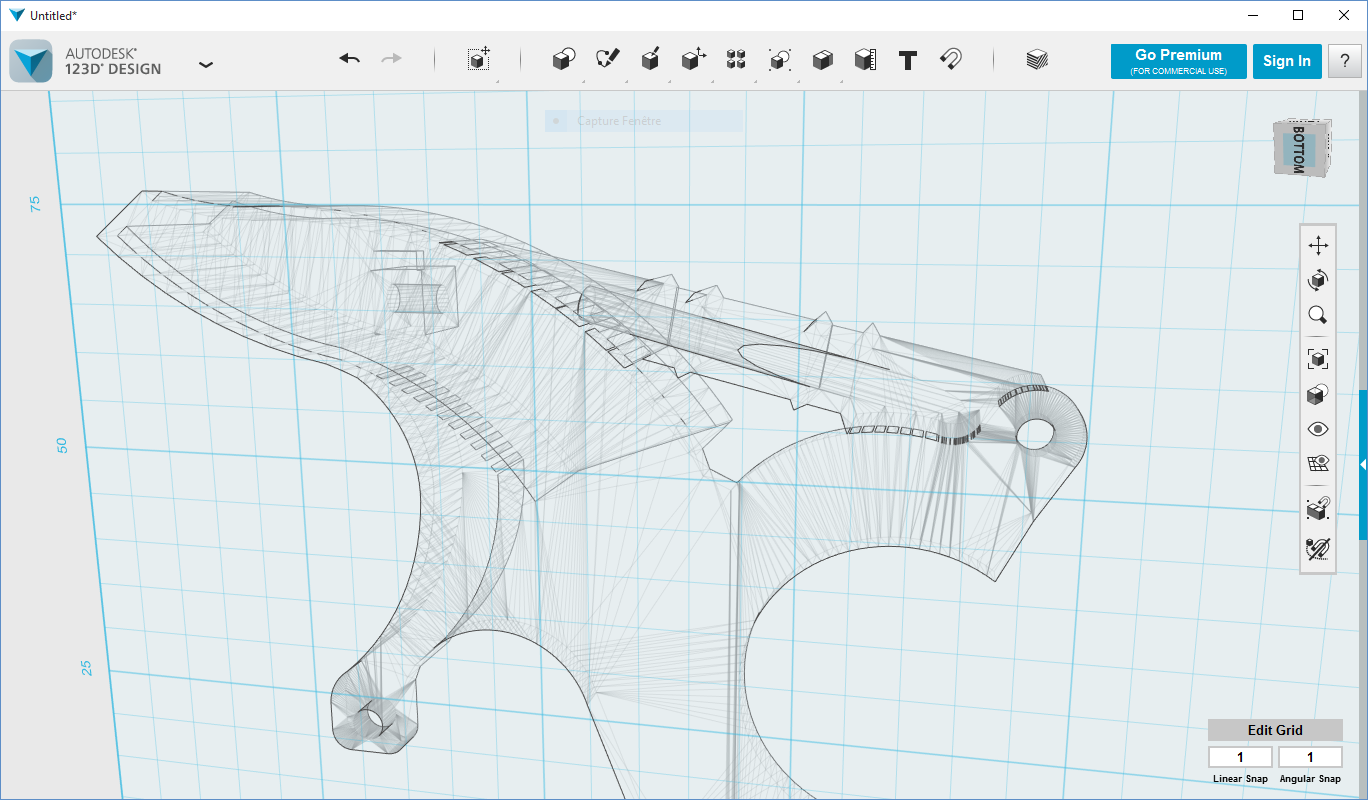

Lowering speed is helpfull, but settings in prusa slic3r is slow enough. Can you post photo of your first layer?

Octoprint makes no difference if used only for gcode sending.

Re: Problems with PLA sticking to the print bed

Hi Michael,

Firstable, it should be a good idea to use one of the gcode file provided with the SDcard, so that you could know if it's a printer issue (calibration ..), or if it's related to one of the parameters used in the slicer.

another thing to check: Try with a first layer height at 0.23 mm. That also means that the calibration should be done with regular thick paper (or business card) in his case. In slic3r, it's defined there:

and do not feel depressed, failing is learning 😉

I'm like Jon Snow, I know nothing.

Re: Problems with PLA sticking to the print bed

Well, I'm not sure what was causing it but so far I have printed a few small things today with 100% success. I switched to a new spool of filament that came in, and I adjusted the first layer to 0.23mm and 50% speed as suggested and so far I have had success printing in both 100um and 200um resolutions. More than likely the original filament is fine, and the slicing adjustments were the key. Either way, its up and running! Thanks everyone for the great help.

Can't wait to order my MK2 upgrade tomorrow! 🙂

Re: Problems with PLA sticking to the print bed

I always get success with UHU glue stick on the bed with PLA, or hairspray my new choice, it releases the prints better after cooldown. The heated bed needs to be at 60 deg C In both cases. With UHU Glue stick use a very razor sharp spatula to remove the print from the glass after cooldown. With hairspray/similar the prints pop off easily after cooldown.

Hairspray or similar works well with PETG.

My UHU sticks I buy from E3D here in the UK.

First layer is the key. Too high or too low, Z home, you will fail. The bed should be level as best can be. You need to calibrate Z better maybe. Once an overal Z height is chosen adjust the bed at each corner, in an order. ie lower left NW upper right SE lower right ie NE and then lower left SW.. As you face printer bed. And then check again. The printer Z level should be checked at ABS temp and bed heat. I suggest unloading filament before, as it can ooze and affect the measurement. I use a thin card provided with another printer to check the Z level at many points manually. Once it is set if often does not need chainging, unless upset when removing the glass bed. For cleaning.

With the new MK2 Prusa I3 this will no longer be an issue. It is detected and adjusted in software like my Kossel Mini I own with Duet Electronics and a differential I/R height sensor from David Crocker.

Except instead of I/R , magnetic proximity sensing is done with the new MK2 Prusa I3.

Nigel

Life is keeping interested and excited by knowledge and new things.

Re: Problems with PLA sticking to the print bed

I use Simplify 3D and Josefs PLA settings mostly. I get fantastic prints. I mod them for other materials.

Nigel

Life is keeping interested and excited by knowledge and new things.

Re: Problems with PLA sticking to the print bed

Two things that really improved print to bed adhesion for me :

* 60 degrees C as platform temp

* Polymaker PLA

I also use a little hairspray now and then for prints that have a small contact area.

Bit more off-topic :

Polymax is also a good material but it warps. Impossible to print without a raft. The raft works as an insulator for the platform heat, resulting in a more uniform temperature throughout the model. Uneven temperature in your model equals uneven thermal expansion forces equals bending and twisting in a structure where those are the only degrees of freedom to dissipate those forces.

That is warping. All the other explanations I found were basically physically unsound.

So a raft combats warping by :

* having a large contact area

* is a sparse structure that allows micro bends and twists

* insulates the more solid part of the structure from the high heat of the bed

Re: Problems with PLA sticking to the print bed

Since I last posted on this thread, I had received two new spools of PLA made by Hatchbox, and adjusted first layer height to 23mm and first layer print speed to 50%, and I have printed a whole lot of things, 99.9% completely successfully with the Hatchbox PLA. So, today I decided to try switching back to the PLA supplied with the printer (because it is Ivory and I wanted something whitish). Using the same settings and bed prep (just putting on a layer of glue) as I had been doing with no problems with the Hatchbox PLA, and the first layer was complete junk and I canceled the print. The bed hasn't been cleaned in a while, and I definitely need to do that, but the Hatchbox PLA has no problems at all printing, in fact I just finished printing something right before. Could this be faulty PLA? I'm thinking about just tossing it out, though I'd hate to do that if it can still be used. I saw mention of a hotter bed earlier, upping the temp to 60C?

Re: Problems with PLA sticking to the print bed

A little off topic but I tried Hatchbox's ABS and have had wonderful results. More successful prints than the supplied PLA. Have you tried blu painter's tape? It works good for me, sometimes to much so thats its a pain to remove the part after it has cooled down. I would try it before you give up on the roll. I get that each roll is different and require changing the settings to find the perfect setup, but not getting a successful print is a bit much. I don't think anymore can really be done on your part unless you change the surface the PLA is adhering too, i.e. Blue tape.

Re: Problems with PLA sticking to the print bed

jarred, thanks for the suggestion, but during my initial run with this problem, I did try blue painters tape, as well as hairspray and everything else I could think of. Shortly after this failed print, my brother came over and I wanted to show him how it works so I switched to my blue Hatchbox PLA and printed him a whistle (one I downloaded from thingiverse with the pea inside). All I did was put down a quick bit of kores glue, loaded it in Octoprint and hit print. When it was finished the thing was flawless and stuck to the glass so well I had to get a scraper and work it off.

Re: Problems with PLA sticking to the print bed

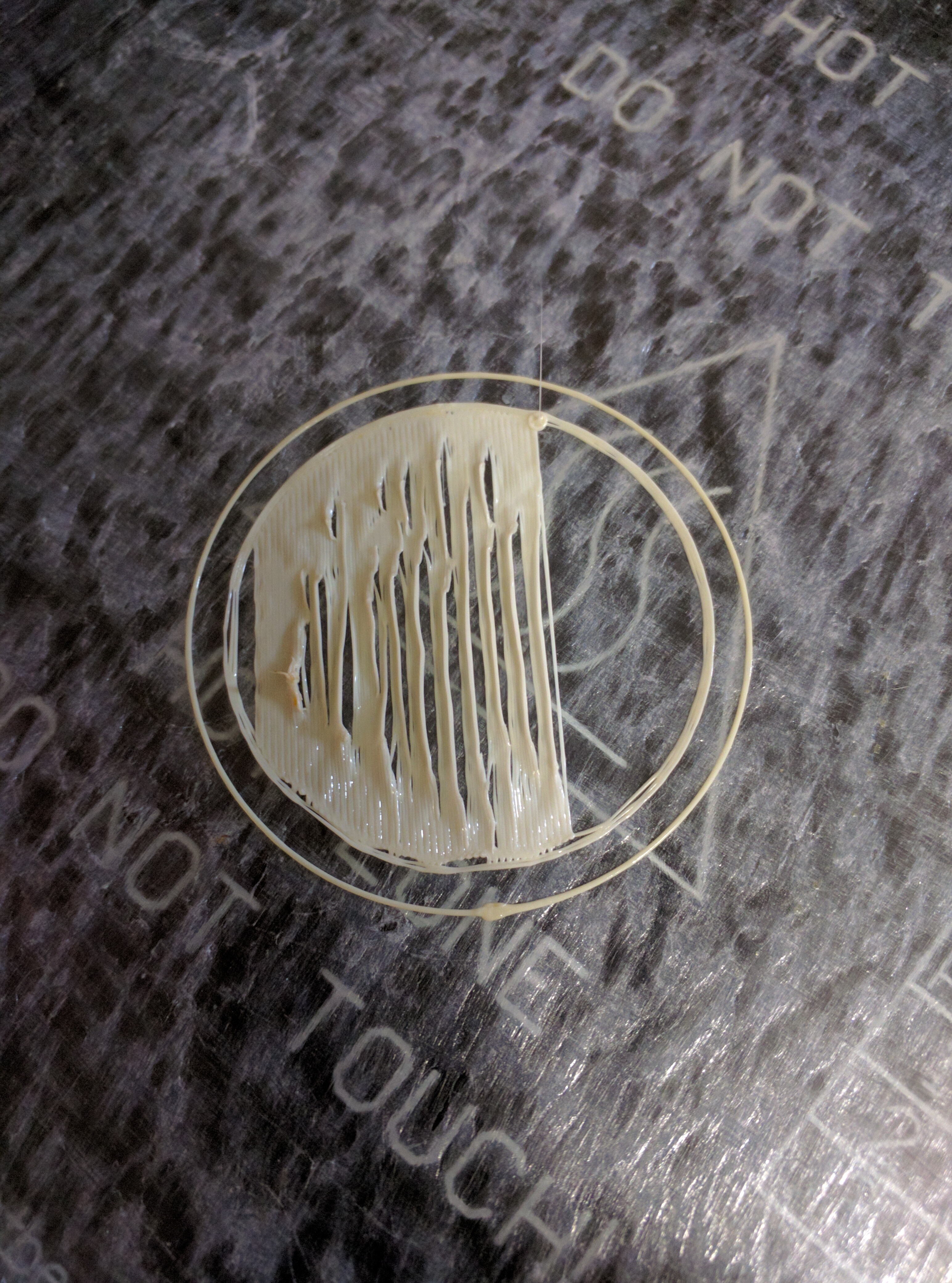

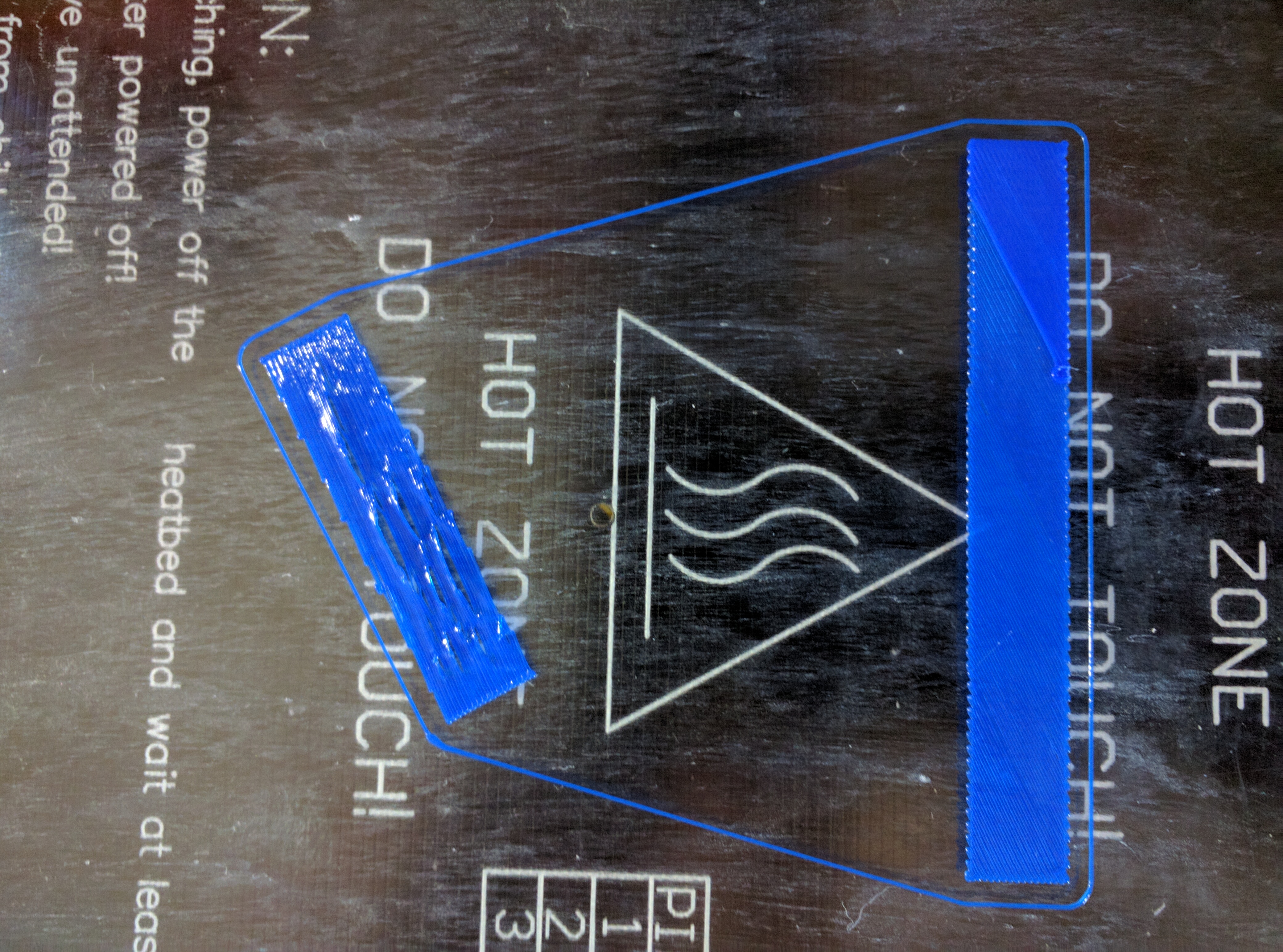

Well, I no longer think it has anything to do with the PLA that came with the machine. I was just trying to print something with my blue PLA and was having the same issue, but only in one spot. I cleaned the tempered glass completely, and reapplied the glue stick. Same thing. I added more glue, and got the same thing. I tried upping the bed temp to 60C and again, the same issue. Looking at the last photo, the problem occurred in approximately the same spot as this time too. I used my IR thermometer to check various areas, and while the lower right corner was way lower than it should be (as others have indicated on the forum), the problem area was in the 49-50C range. Could it be something wrong with the glass itself? Notice in the image below that the left side is completely garbage and lifting off the glass, while the right side is perfect. I've just finished trying this print about 7 times, each time failing in the exact same way. The first time was before cleaning the glass completely.

I have tried several times to print multiple copies of some small thing, and it has failed every time. Now that I think about it, I believe the problem happened around this area of the bed every time.

Re: Problems with PLA sticking to the print bed

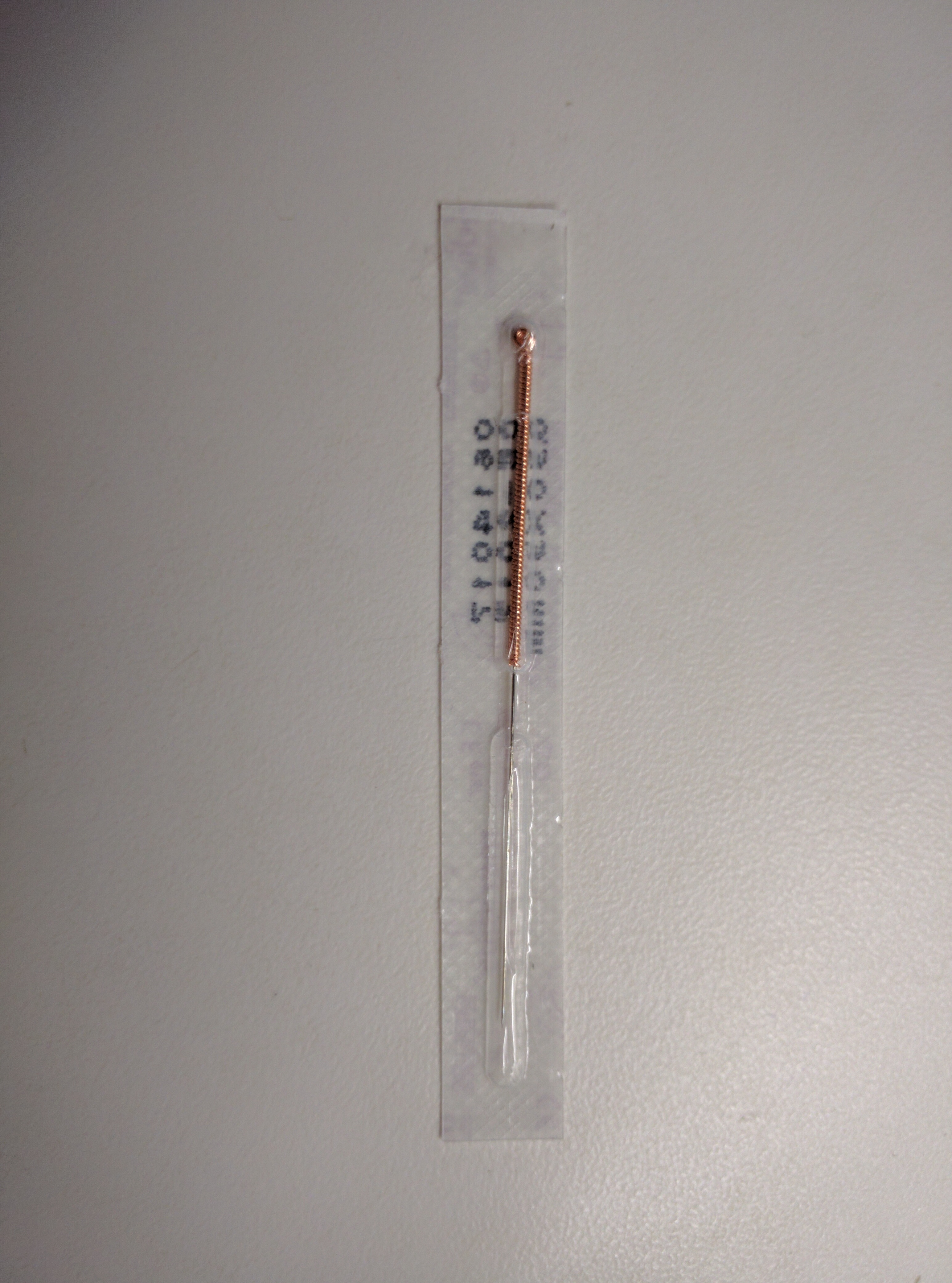

Oh, I forgot to mention that a couple of days ago I found the thing pictured below that was included in my kit. I don't recall seeing it mentioned in the build instructions and it got set aside and forgotten. Could it be something important?

Re: Problems with PLA sticking to the print bed

Michael,

Have you tried cleaning off the glue and starting again with only a couple of thin layers? It may just be the lighting in your pictures, but it looks like you have a lot of glue on the glass. I've noticed that as the glue builds up, the adhesion gets worse for me, so I typically clean the glass and start over after 4-5 prints.

Actually, I have two pieces of glass, so there is always a clean one in reserve ready to go. When I initially apply the glue, I typically do two quick coats of glue stick applied perpendicular to each other so the second coat fills in the gaps/streaks I missed with the first coat. When cold, you can barely see a film on the glass, and it becomes clear when heated. In between prints, I do a quick single layer touch-up where the object was located. If after 4-5 prints I really notice obvious glue on the glass when cold, that triggers me to clean it off and start over.

Also, my kit didn't include anything that looks like that object. What is the diameter of the pointy end of it? Could it be a tool for cleaning the nozzle?

take care,

Roger

Re: Problems with PLA sticking to the print bed

Hey roger, yes as I indicated in the post with the blue print picture I cleaned the glass completely and did a single careful layer of glue and the exact same thing happened. I forgot to mention that I then flipped the glass over and did a slightly heavier coat of glue and again got the same result once again.

As far as the object, I looked at it under a magnifying glass and some of the writing indicates that it is an acupuncture needle! haha. I didn't expect that. It is inicated as 0.3 x 30mm, so I suspect you might be correct as far as it being a tool for cleaning the nozzle.

Re: Problems with PLA sticking to the print bed

Yes the accupuncture needle is for clearing blocked nozzles. They have never worked for me. If you have under extrusion you may have a partially blocked nozzle. I use the Ulitmaker Atomic method with some variations across the other different 3D printers I own. Including the Prusa I3, I lower the idler before the push/pull It works everytime.

https://ultimaker.com/en/resources/149-atomic-method

Nigel

Life is keeping interested and excited by knowledge and new things.

Re: Problems with PLA sticking to the print bed

I don't have under extrusion, as I understand it. I am having sporatic bed adhesion issues, but I think it's more down to my inexperience than anything. After my last post, I cleaned my glass again, and this time just put down a quick spritz of hair spray and was able to print the job I was trying to earlier with no problems. I also did 4 more afterward with no problems also.