Problem while printing first layer

Hi guys,

I have a new printer about 3 month, printing PLA for the last couple of month and everything worked smoothly, I printed a several versions of a box and all worked as expected. One day I changed my fillement to laywood, and it printed pretty good a nice box for 9 hours. the box turned out great.

than, I changed fillement back to my PLA, from that moment, nothing is working anymore, no matter what I do, I even reset to factory and go over this page again:

https://shop.prusa3d.com/forum/prusa-i3-kit-building-calibrating-first-print-main-f6/-before-you-ask-troubleshooting-video-updated--t472.html#p39190

All seemed to be leveled up, I remove the nozzle and put it in Acetone, cleaned it, and cleaned the bed, but still I'm getting bad results on the first layer, it's like the fillement is dragging or something, can't get the first layer right no matter what i do. adjusting Z didn't work, it's 3 weeks of trying. the images as follow (3 images):

https://imgur.com/a/qCgjf

Re: Problem while printing first layer

Can you show us the photos of the calibration square from step 6?

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…

Re: Problem while printing first layer

currntly the nozzle is back to Acetone because I want to retry clean it again (had no idea what to do, so I'm repeating steps again).

Once it I clean it I will show the squre, but just to explain, the calibration square is still doint this issue it's like the nozzle grabing the end of every line and making it fold. It never happend to me before, but now, it seems to happen all the time now, at random areas on the table.

I will post the sqare soon, but do you have any clue or direction fot this to happend?

Re: Problem while printing first layer

currntly the nozzle is back to Acetone because I want to retry clean it again (had no idea what to do, so I'm repeating steps again).

Once it I clean it I will show the squre, but just to explain, the calibration square is still doint this issue it's like the nozzle grabing the end of every line and making it fold. It never happend to me before, but now, it seems to happen all the time now, at random areas on the table.

I will post the sqare soon, but do you have any clue or direction fot this to happend?

If a print is curling up and the nozzle is grabbing it that is a sign of poor adhesion or poor slicer settings. (This is for PLA - other filaments are different.)

Poor adhesion is likely a poor Live Z calibration or a dirty (oil) bed.

Poor slicer settings can be a hole host of things.

To determine these, I suggest the following:

If the cal square looks good (post a picture), print something from the SD card. (Prusa Logo)

If that curls, you should make sure your bed is very clean - wipe with acetone.

If the Logo is okay, but your sliced items are having problems, it is a slicer setting. Post them and we will look.

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…

Re: Problem while printing first layer

EDIT: please ignore the below information for now, I'm currently fixing this leaking issue (mentioned below) using this link: . (seems I put the nozzle while it wasn't at full heat.. :/

Hold on to what you about to see... i have never seen this one before...

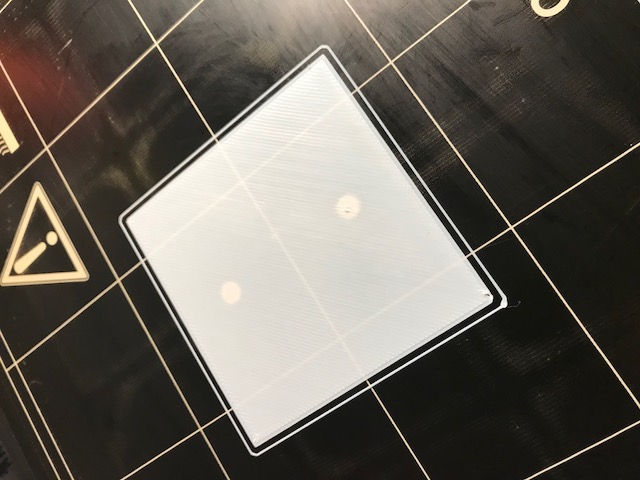

okay, so I cleaned the nozzle, and burn it with a touch burner, and put it in Acetone again. then, I cleaned my bad again, then I printed the calibration surface which looks almost perfect:

https://imgur.com/a/CcHoj

But, when I print somehting else, which is not the calibration surface, it will make the nozzle stick the PLA into it, grabbing it from the bad, so I tried to push Z a bit more, which made the first layer almost OK, but then, something spilled from the nozzle,

and one more thing, the whole nozzle seems to feel with we sticky PLA, which didn't happend at the start of the print.

Seems like a leaking ? here is some picture of the weird things that going on:

here is the spilled part: https://imgur.com/a/v35Ut

and here is the leaking: https://imgur.com/a/adm7B

finally, some reasons for this bad prints, but any idea what should I do now? how to find the leak? or what happend? (OR, how did it happend? I never touch it, it always worked great... why now? what did I do?)

Re: Problem while printing first layer

so I heat the printer to 295 degrees and put the nozzle back tight (after cleaning everything).

I recalibrated everything, and adjust Z, and printed the surface, here is a picture:

Note that surface print is in the middle of the bed, and seems like there is no issue.

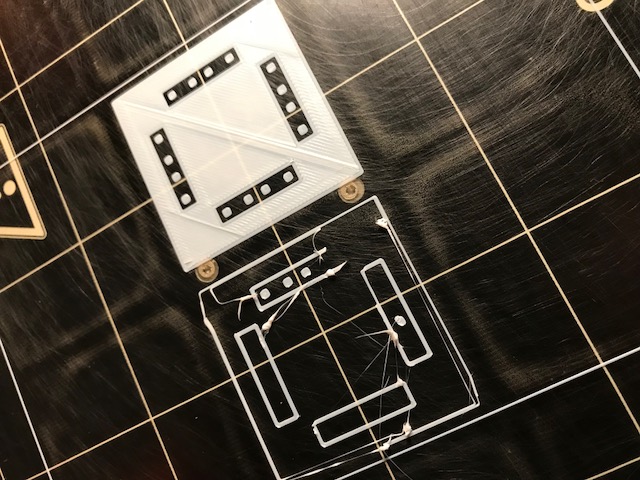

now, trying to print my own box using PrusaControl to convert to gcode, and start getting those weird PLA pull:

https://imgur.com/a/LUqAj

https://imgur.com/a/jGPlY

https://imgur.com/a/UPnzM

NOTE that I had never have those problems before, and have no idea why it happend now.

why those pulls of PLA happens. One thing though, it seems like the pulling always happend when the extruder finish a line and turning to continue the next line... seems like it..

I am currently clueless... have no idea what to do.. where do we go from here?

Re: Problem while printing first layer

I have printed the prusa logo and it looks perfect:

https://imgur.com/a/vk68w

So as you said, if prusa logo is OK, I guess it's a slicer settings, but I'm using PrusaControl slicer with the default settings, they do not provide the settings (only in the generated GCODE) and i edit only quality of 0.2, and infill 20% and support "everywhere".

and just generate the gcode.

BTW i can post here the end of the file of the GCODE, which shows a lot of settings:

this can be found at the top of gcode:

; generated by Slic3r 1.37.1-prusa3d-win64 on 2017-10-12 at 23:03:24

;

; external perimeters extrusion width = 0.42mm

; perimeters extrusion width = 0.45mm

; infill extrusion width = 0.45mm

; solid infill extrusion width = 0.45mm

; top infill extrusion width = 0.42mm

; support material extrusion width = 0.35mm

; first layer extrusion width = 0.42mm

and this can be found at buttom:

; Filament-specific end gcode

;END gcode for filament

G4 ; wait

M104 S0 ; turn off temperature

M140 S0 ; turn off heatbed

M107 ; turn off fan

G1 X0 Y200; home X axis

M84 ; disable motors

; filament used = 22564.1mm (54.3cm3)

; total filament cost = 0.0

; avoid_crossing_perimeters = 0

; bed_shape = 0x0,250x0,250x210,0x210

; bed_temperature = 55

; before_layer_gcode = ;BEFORE_LAYER_CHANGE\n;[layer_z]\n\n

; bridge_acceleration = 1000

; bridge_fan_speed = 100

; brim_width = 0

; complete_objects = 0

; cooling = 1

; default_acceleration = 1000

; deretract_speed = 0

; disable_fan_first_layers = 1

; duplicate_distance = 6

; end_filament_gcode = "; Filament-specific end gcode \n;END gcode for filament\n"

; end_gcode = G4 ; wait\nM104 S0 ; turn off temperature\nM140 S0 ; turn off heatbed\nM107 ; turn off fan\nG1 X0 Y200; home X axis\nM84 ; disable motors

; extruder_clearance_height = 20

; extruder_clearance_radius = 20

; extruder_colour = #FFFF00

; extruder_offset = 0x0

; extrusion_axis = E

; extrusion_multiplier = 1

; fan_always_on = 1

; fan_below_layer_time = 100

; filament_colour = #FF14E2

; filament_cost = 0

; filament_density = 0

; filament_diameter = 1.75

; filament_max_volumetric_speed = 0

; filament_notes =

; filament_soluble = 0

; filament_type = PLA

; first_layer_acceleration = 1000

; first_layer_bed_temperature = 55

; first_layer_extrusion_width = 0.42

; first_layer_speed = 70%

; first_layer_temperature = 215

; gcode_comments = 1

; gcode_flavor = reprap

; infill_acceleration = 2000

; infill_first = 0

; layer_gcode = ;AFTER_LAYER_CHANGE\n;[layer_z]

; max_fan_speed = 100

; max_layer_height = 0.25

; max_print_speed = 100

; max_volumetric_extrusion_rate_slope_negative = 0

; max_volumetric_extrusion_rate_slope_positive = 0

; max_volumetric_speed = 0

; min_fan_speed = 85

; min_layer_height = 0.07

; min_print_speed = 15

; min_skirt_length = 4

; notes =

; nozzle_diameter = 0.4

; only_retract_when_crossing_perimeters = 0

; ooze_prevention = 0

; output_filename_format = [input_filename_base].gcode

; perimeter_acceleration = 800

; post_process =

; printer_notes =

; resolution = 0

; retract_before_travel = 1

; retract_before_wipe = 60%

; retract_layer_change = 1

; retract_length = 0.8

; retract_length_toolchange = 4

; retract_lift = 0.6

; retract_lift_above = 0

; retract_lift_below = 199

; retract_restart_extra = 0

; retract_restart_extra_toolchange = 0

; retract_speed = 35

; single_extruder_multi_material = 0

; skirt_distance = 2

; skirt_height = 3

; skirts = 1

; slowdown_below_layer_time = 25

; spiral_vase = 0

; standby_temperature_delta = -5

; start_filament_gcode = "; Filament gcode\n"

; start_gcode = M115 U3.0.12 ; tell printer latest fw version\nM83 ; extruder relative mode\nM104 S[first_layer_temperature] ; set extruder temp\nM140 S[first_layer_bed_temperature] ; set bed temp\nM190 S[first_layer_bed_temperature] ; wait for bed temp\nM109 S[first_layer_temperature] ; wait for extruder temp\nG28 W ; home all without mesh bed level\nG80 ; mesh bed leveling\nG1 Y-3.0 F1000.0 ; go outside pritn area\nG1 X60.0 E9.0 F1000.0 ; intro line\nG1 X100.0 E12.5 F1000.0 ; intro line

; temperature = 210

; threads = 4

; toolchange_gcode =

; travel_speed = 120

; use_firmware_retraction = 0

; use_relative_e_distances = 1

; use_volumetric_e = 0

; variable_layer_height = 1

; wipe = 1

; wipe_tower = 0

; wipe_tower_per_color_wipe = 0

; wipe_tower_width = 0

; wipe_tower_x = 0

; wipe_tower_y = 0

; z_offset = 0

; clip_multipart_objects = 1

; dont_support_bridges = 0

; elefant_foot_compensation = 0

; extrusion_width = 0.45

; first_layer_height = 0.2

; infill_only_where_needed = 0

; interface_shells = 0

; layer_height = 0.2

; raft_layers = 0

; seam_position = nearest

; support_material = 1

; support_material_angle = 0

; support_material_buildplate_only = 0

; support_material_contact_distance = 0.15

; support_material_enforce_layers = 0

; support_material_extruder = 0

; support_material_extrusion_width = 0.35

; support_material_interface_contact_loops = 0

; support_material_interface_extruder = 0

; support_material_interface_layers = 2

; support_material_interface_spacing = 0.2

; support_material_interface_speed = 100%

; support_material_pattern = rectilinear

; support_material_spacing = 2

; support_material_speed = 50

; support_material_synchronize_layers = 0

; support_material_threshold = 45

; support_material_with_sheath = 0

; support_material_xy_spacing = 60%

; xy_size_compensation = 0

; bottom_solid_layers = 5

; bridge_angle = 0

; bridge_flow_ratio = 0.95

; bridge_speed = 20

; ensure_vertical_shell_thickness = 1

; external_fill_pattern = rectilinear

; external_perimeter_extrusion_width = 0.42

; external_perimeter_speed = 30

; external_perimeters_first = 0

; extra_perimeters = 0

; fill_angle = 45

; fill_density = 20%

; fill_pattern = cubic

; gap_fill_speed = 40

; infill_every_layers = 1

; infill_extruder = 1

; infill_extrusion_width = 0.45

; infill_overlap = 25%

; infill_speed = 60

; overhangs = 1

; perimeter_extruder = 1

; perimeter_extrusion_width = 0.45

; perimeter_speed = 40

; perimeters = 3

; small_perimeter_speed = 20

; solid_infill_below_area = 0

; solid_infill_every_layers = 0

; solid_infill_extruder = 1

; solid_infill_extrusion_width = 0.45

; solid_infill_speed = 40

; thin_walls = 0

; top_infill_extrusion_width = 0.42

; top_solid_infill_speed = 20

; top_solid_layers = 6

Re: Problem while printing first layer

Okay, we have systematically found that the issue is either your model, or your slicer settings. (I have looked at the settings - quickly - and saw nothing obvious.)

Let's check to see if it is the model or the slicer settings. Please slice, and print this item:

https://www.thingiverse.com/thing:763622

(This is a good test item to see if your printer is working up to snuff. I know you can get a pre-sliced one, but I want to see if your slicer is doing the correct things.)

IF this prints well, when you sliced it, then there is something about your model that is making the slicer not work well (e.g. bottom is not flat or is too thin, or need supports or...)

If this has a problem also, then somehow you are using PrusaControl incorrectly.

(This is just a hypothesis, but I am guessing your model is needing supports and what you are seeing it print is either the raft or supports that your model requires. If you post a screen capture of the draft version of the model from the slicer we should be able to see how the first layer is supposed to look - or you could put you .gcode into http://gcode.ws and look at what the first layer is doing.)

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…

Re: Problem while printing first layer

Ok,

so I printed the boat, but it stops in the middle of the print after 56 minutes, i thought something went wrong, so I did it again, and it stops again at 56 minutes, the weird thing is, the fan keep running, and the bed + nozzle are still heated, even an hour after the print, no idea what is the reason for this, but the both half boats turn out to be the same because the printer stop at the 56 minutes for them both ( still the prints looks good)

here it is:

my printer screen where it stops shows this:

https://imgur.com/a/UuhBH

and here is print quality (inside the link you should scroll down to see all):

NOTE: the reason for the big hole in the boat is because the printer just stops there in the middle of the print, and the nozzle just stayed there, so u have the ugly hole, but it is not a result of bad print:

https://imgur.com/a/8vogN

Any idea why it just stops the twice exactly at the same time, and also keep heatbed and nozzle still warm?

regarding my model which I originaly wanted to print, I know that the issues which I shown in the pictures of my model is comming from the support meterial, because I already printed this model abou 15 times before (and turn out great), and I can identify that this lines which are coming out (or dragged) of the printer bed are support. maybe after this dragging, all the non-support also gets ruined,,

here is a picture of gcode from gcode.ws:

https://imgur.com/a/u3Zi6

I can also upload my files somewhere so u can see them,

1) my boat gcode - and why it is stoping at 56 minutes

2) my model gcode.. and why my support sux =)

Re: Problem while printing first layer

I use Slic3r, not Prusa Control, so I am guessing.

It is possible you "quit" Prusa Control before it was through writing the .gcode file. If so, the commands would just stop wherever it was writing when you hit quit. You can check by opening the file, and looking at how it ends, and see if it has the normal comments on all the settings.

You should be able to fix that by re-slicing it, and making sure it is through writing before quitting the application.

The benchy looked nice - up till it stopped.

---

Now for your slicing of your other model. It seems to be a model that needs supports. E.g. it is a more complex model. I have no experience with PrusaControl, but I know the Slic3r has much more control over things and is worth learning if you are slicing more complex things. The extra control is helpful when you want to control the intent of your actions.

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…

Re: Problem while printing first layer

Found this while searching for my own solutions, I'm not trying to highjack your thread but I think my own experiences are similar enough that they might help narrow down whatever is going on.

I've had the printer about the same amount of time and was printing about 2 months perfectly. All PLA for me but after a nasty nozzle jam I pulled apart the hot end and it's just never worked right since then. It's not that the first layer doesn't stick, it's that it doesn't always stick seemingly dependent on the motion of the X and or Y axis'. Same as you I can print the cal squares to perfection, and can do the same with benchy and I think it has to do with the object footprint and X movements on a 'more complicated' first layer.

My example is D&D tiles, and the reason I'm not fully convinced it's the slicing alone. I'm still attempting to print the same gcode that was working flawlessly from before and running into issues whenever there is wide mechanical movements between the extrusions of the first layer, or on support layers that are not pressing against one another. The right side prints first and seems okay enough but then the shift to the left has adhesion issues, I thought it was bed leveling but it's not. If I slice it again and start on the left model the inverse will be true, the left will stick and not the right.

Anyways, I do have some solutions on the more complicated models. I can print again but not with the same settings with the same PLA and Gcodes as before so it's "fixed" but not back to what it was. Since you're using PrusaControl I'll stick to the easiest first. During the first layer with a known good Z height turn the speed to %50 on one of your more complex box prints, watch the nozzle if you can for adhesion issues during the turns of the first layer. Unfortunately some of the other things that have worked for me will not work for Prusacontrol to my knowledge 🙁

Re: Problem while printing first layer

first, thank you guys for helping me.

I found that what you are saying is very close to my issue, I moved to 50% for first layer (also never needed to do that on old prints of the same model) and it fixed the issue.

currently I'm waiting for the second layer, but right seems like first layer is perfect so far (which is a good + bad news, because it takes for ever to print the first layer, but at list I'm back in business for printing my own box ).

regarding the issue itself, when I look at the nozzle while it start the first layer print, seems like when it is in the begging of every boarder print the PLA curls, every time it go to new x/y point and start pushing PLA again, then the curl start, at this moment, which is actually the start of every shape. and another thing, I can only guess that the nozzle pushing out PLA before it is fully down, which makes the PLA have a lift and curl.

- I currently took aaron.s5 regarding learning the slic3r, but I also used simpliy3d.

- I also took your advise regarding 50% print for first layer and it is actually printing ( seems like a good news, but also bad news 🙂

I only have 1 question, if anybody knows which parameter should I change regarding the issue I described above (assuming the curls are coming from those reasons), I want to delay the nozzle extrusion when it starts a new x/y ... it probably tune the printer to a some level..

Any idea ? 🙂

Re: Problem while printing first layer

If your printer stops randomly, you may have a broken SD card.

If the print does not stick to the PEI sheet, you may have the PEI sheet contaminated with a silicon based grease. This may happen if you use a silicone based hand cream. Anyway, you may try to de-grease your PEI sheet with an acetone soaked paper towel.