Problem Solved: After 45 days of continous printing, 1st maint needed on wiring harness (factory built MK2)

All,

I have been printing non stop since the factory built MK2 arrived, I am very impressed with the MK2. Just recently the fan started to cut out during a print.

It is time for my first maintenance to get the MK2 back running again. I am still stoked because compared to my other 3D printer which is very good, the MK2 has been exceptional.

I will take apart the wiring harness to look for the fault but tips regarding the wiring harness failure would be welcomed.

- Is there something that fails with this setup like a connector coming undone

- Are there any precautions I should be aware of like having the MK2 unplugged so I don't short out anything

- Once I fix the problem, is there anything I can do to future proof from failures,

-- using super glue to keep a connector from coming undone

-- Add extra filament into the wire harness to provide strain relief ( I have some PETG filament)

-- Add a small nail or electrical copper wire to just into the wire wrap at the print head to prevent flexing that would extend only to the length of the orange box shown below.

-- Use thicker zip ties

-- use silcone wire that flex more

-- use a different gauge of wire

-- put shrink wrap on red and black wires to prevent flexing

I know others have gone with the cable chains, but I need to get the MK2 operational again to print them.

- For those who have switch to cable chains, what is your opinion of the upgrade.

- For those who have tried the chains and switched back to the default setup, why did you change your mind

- Has anyone printed the cable chains in PLA, did it hold up?

Thanks for any information that you can provide.

Dave

Re: After 45 days of continous printing, 1st maint needed on wiring harness (factory built MK2)

Are these the chains people are using?

Re: After 45 days of continous printing, 1st maint needed on wiring harness (factory built MK2)

As an improvement, I am thinking about hooking up a LED to the fan. This would give visual feedback just like the heatbed does when power is being sent to the fan.

If the connection to the cooling fan goes bad the LED will go out I can see it on the remote camera I use that is hooked up to OctoPrint.

Thoughts?

Re: After 45 days of continous printing, 1st maint needed on wiring harness (factory built MK2)

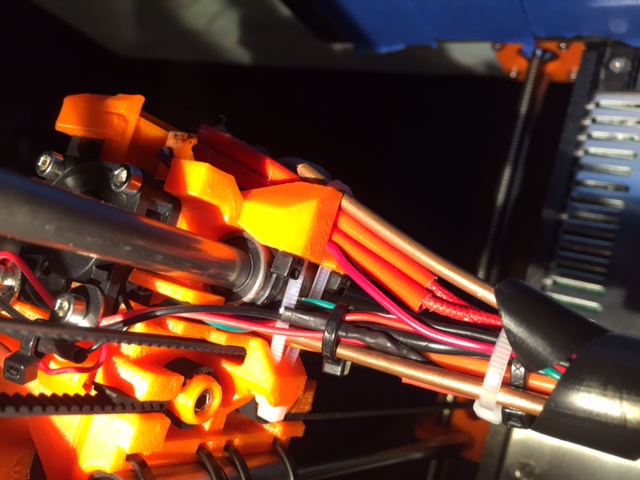

I took apart the wiring harness to find the fault was the connection came apart from the original fan wire and the wire in the harness .

Here is the failure point of my factory built MK2 with the shrink wrap cut off. Visually everything looks intact, but using a multimeter reveals intermittent contact.

I am working on a solution that involves the following:

- Using more shrink wrap so the solder joint is not flexed

- Using better wire that will take stress

- Using a zip tie segment under the shrink wrap to take off the stress of the fan wire much like the filament in the wire harness

-making sure there enough loose wire so the connection joint is not under stress

Re: After 45 days of continous printing, 1st maint needed on wiring harness (factory built MK2)

The same thing happened to me as I posted in my other thread. I fixed it by soldering the wire where it was cut internally but if your setup is the one in the picture I am not sure how it would have happened since it looks that it doesn't have the same stress point as it normally has.

I am curious about the cable chains too I really would like to avoid them and I believe that is something that we are doing wrong since Prusa print farm doesn't use cable chains and those printers are running constantly if it was a problem it would have happened to those machines 100 times over

Re: After 45 days of continous printing, 1st maint needed on wiring harness (factory built MK2)

So my solution involves the following:

- Replacing the wire coming from fan (silver color meaning AL or tin) w/ copper wire

-- it seems like the original wires from the fan are not thick enough to handle all the movement from the head

- The upgraded copper wire feeds into the wire harness

- Putting washers at the top two screws hold the original fan wires in place to make sure there is no stress on original fan wires, only the upgraded copper wires are exposed to any kind of movement from the print head going into the wire harness. A zip tie going through the washer holds the original fan wires down.

With copper:

Due to its high ductile properties, copper can be formed into very fine wire, making it more versatile. Copper has a high tensile strength as well, so it can undergo extreme stress but show minimal signs of wear and tear. This makes the wiring more durable than aluminum. Due to its great resilience, high durability, low maintenance, and high performance, copper wiring also adds to home value.

Re: Problem Solved: After 45 days of continous printing, 1st maint needed on wiring harness (factory built MK2)

It seems like the fan and pinda lines are to fragile and will break given enough time. There seems to be agreement that this area has too much flex putting stress on the smaller wires.

I will implement a variation of this solution, replacing the nail with thick copper that is pulled from the AC wire that is fed into a breaker box.

http://shop.prusa3d.com/forum/prusa-i3-kit-building-calibrating-first-print-main-f6/self-test-error-t2724-s10.html#p21624

It also seems like an additional part could be made which would mount to where the two srews are.

Re: Problem Solved: After 45 days of continous printing, 1st maint needed on wiring harness (factory built MK2)

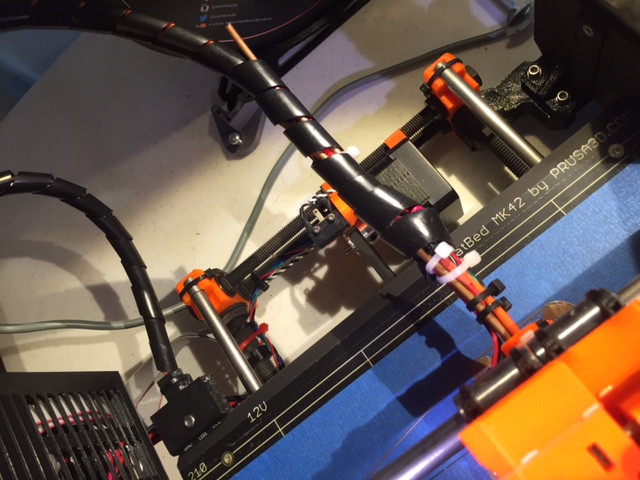

Keeping all original MK2 configuration, but just added to copper wires to control bend and flex point.

The copper AC lines are only zipped tied into place. Moving the print head left and right on the X axis shows flex on the Nylon and the two copper wires.

Copper line stick out of wrap on bottom image just shows how the copper AC line is in the wrap, it can bent to any curve that will provide the low stress to the wires in the harness.

If you try this mod, first thing you should do is autohome. Make sure zip ties do not hit the z-frame when homing.

Also, the copper could be bent upwards if you have tall prints that get pushed over by the cable harness hitting the object.

Re: Problem Solved: After 45 days of continous printing, 1st maint needed on wiring harness (factory built MK2)

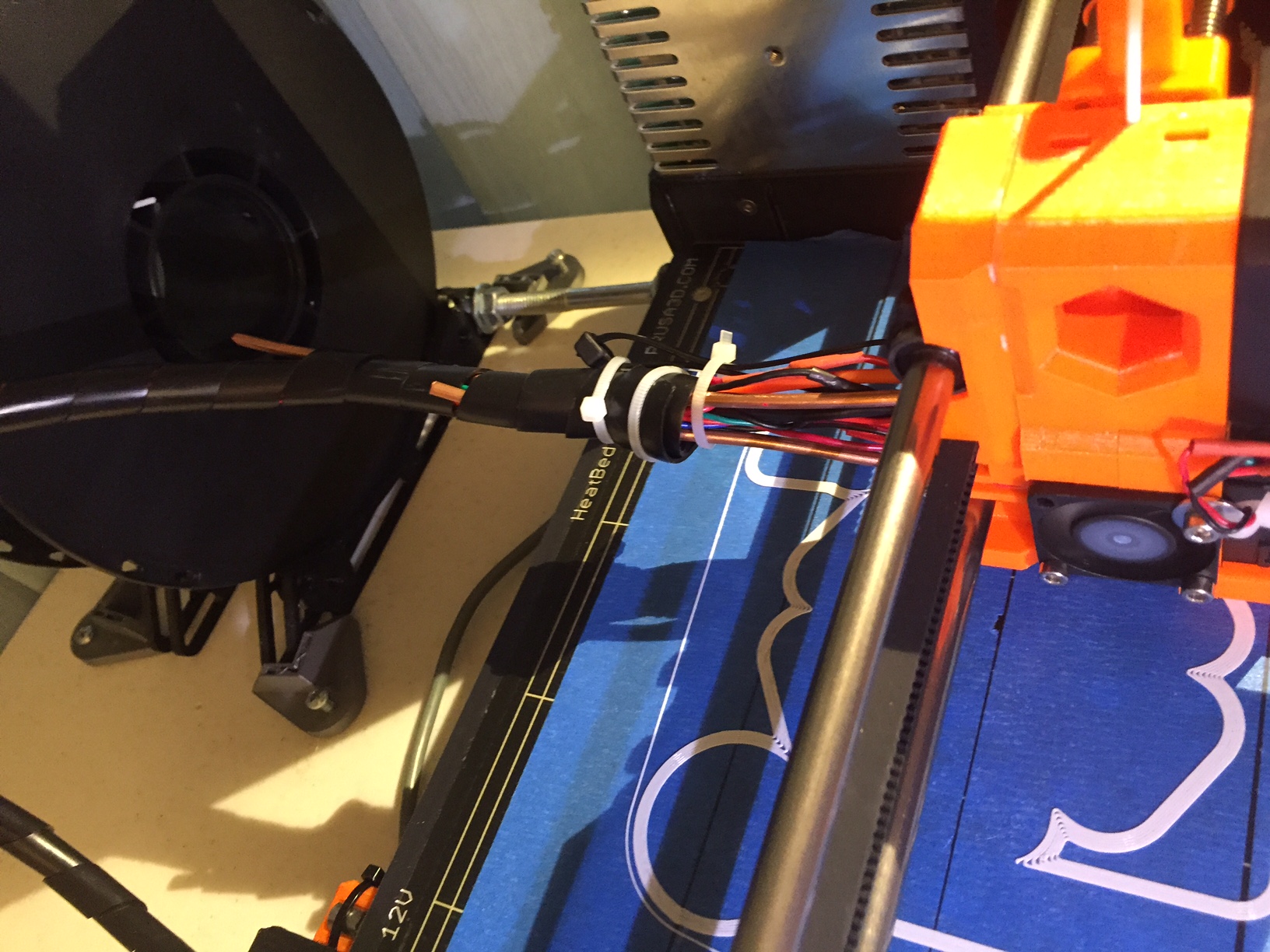

Updated configuration:

- Original fan wires along with upgraded copper wires are tuck under fan, they interfered with the autohome

- Wire wrap pulled back at printhead, with two extra copper AC line supports on to and bottom it was interfering with autohome

- I noticed that the tie wrap on the back rubs against the pinda wires. I place a 1cm segment of zip in such a manner so nothing is rubbing against any wires when the print head moves back and forth the X-axis.

Printing for about a day now without any problems.

Re: Problem Solved: After 45 days of continous printing, 1st maint needed on wiring harness (factory built MK2)

Thanks for all the info about solutions.

We got our Prusa i3 MK2 for Christmas. Two nights ago (first 2 weeks of February), the printer stopped working when checking the bed on the right hand side. Found that the PINDA probe wires had broken inside the insulation right behind the print head where the wires join the head. Upon disassembly, we found that the large cooling fan wires were also damaged such that they had to be in just the right position to work. It appears that the continual movement of the print head puts a lot of back and forth stress on these small wires where they are zip tied on the back of the print head.

After "open heart surgery" on the PINDA probe wires, they were repaired and now work. Next, time to fix the fan wires and we will be back in business.

I came looking to see if anyone else had solved this problem. It seems to me that this printer should last more than 1.5 months.

Re: Problem Solved: After 45 days of continous printing, 1st maint needed on wiring harness (factory built MK2)

Just as a data point, I have another 3D printer that has 4.5 stars out 5 on Amazon.com with hundreds of reviews. It stopped working after a month and only after pressuring the vendor using social media was I able to get a replacement unit.

My take on it is 3D printers are making huge leaps, but right now you have to pick 2:

- User base and community knowledge (MK2 wins)

- Print quality ( MK2 is one of the pack leaders)

- Over $2000 price point, under $2000

Anyone who owns a 3D printer today are in the group who are on the cutting edge and/or bleeding edge of 3D printing.

This reminds me of the smartphone revolution we just had. In the early days just having a color touch screen and not a LCD based flip phone was impressive. Today our smart phones get more use than our computers for the majority of the population. I think this is the same acceleration curve for 3D printers.