Nozzle Body stuck

Hi,

I need some advice.

I followed this guide to replace the PTFE tube: http://manual.prusa3d.com/Guide/How+to+replace+PTFE+tube/82

But I am stuck at step 8, I was able to unscrew the Nozzle body a bit, but now it's stuck half unscrewed. Instead of using pliers, I used the 17 mm spanner to have a better grip.

I tried to heat it at 240 °C, and using protecting gloves I am just able to screw it back a quarter of round (45°) and back to it's position, but that's all it accept to move 🙁

Appart from crying watching my lovely printer half dead, what can I do ? Help !

I'm like Jon Snow, I know nothing.

Re: Nozzle Body stuck

Christophe

It does sound as though you have some plastic in the threads and if that was PLA, heating it to 240 degrees may have burnt it solid...

I think you need to get it to about 175 degrees and then gently back 45 degrees, forward 50 degrees and so on. It should come clear.

The other option (which worked for me) was to get a V6 which has a separate S/S heat break.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Nozzle Body stuck

Thanks for the feedback Peter.

The last filament I used was PLA. But I used ABS and PET before. Maybe there is a mix of various filament matter, melting (and burning) at various temperature ...

What a mess ://

I'll follow your advice, trying lower temperature first, and letting some time to the heater to dilate a bit.

I'm like Jon Snow, I know nothing.

Re: Nozzle Body stuck

Well, after heating up to 200 °C I was able to unscrew the body.

However I think I didn't unscrew gently enough, I damaged the screw part. I think I'll have to change the extruder :/.

I will put some pictures tomorrow, right now I'm a bit in bad mood.

I'm like Jon Snow, I know nothing.

Re: Nozzle Body stuck

Christophe

What part did you damage? the heater block or the heat sink?

You may well find that it will screw back together and hold OK until you get new parts.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Nozzle Body stuck

Hi Peter,

So following the wise words "Things always look better in the morning " I had another look this morning.

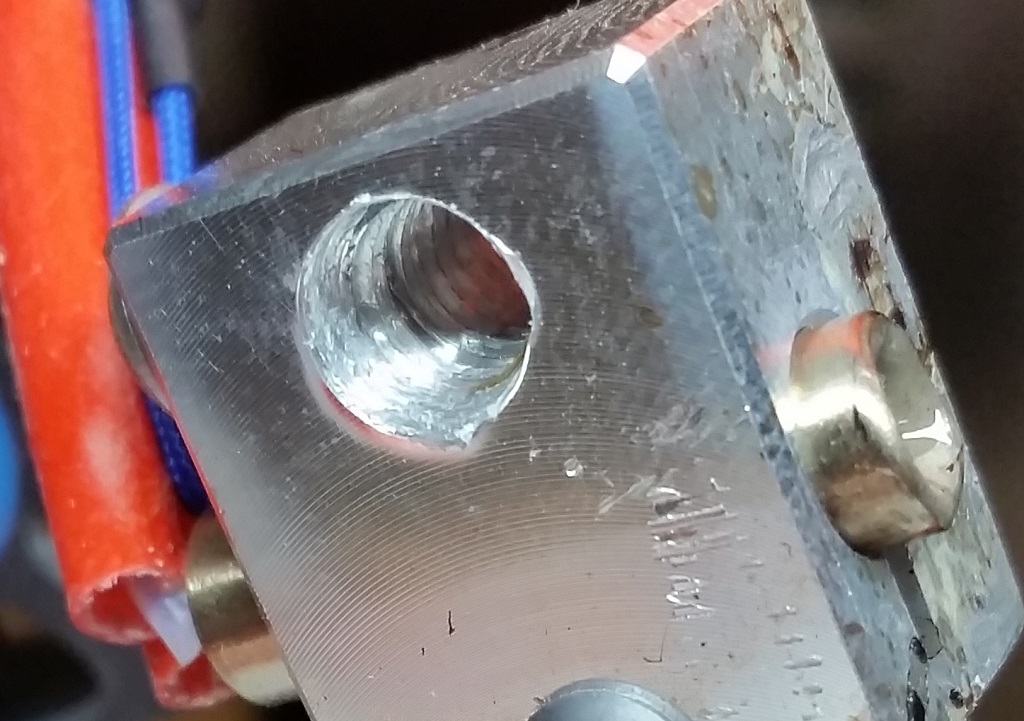

The heatsink screw thread have some kind of metal attached/glue to it:

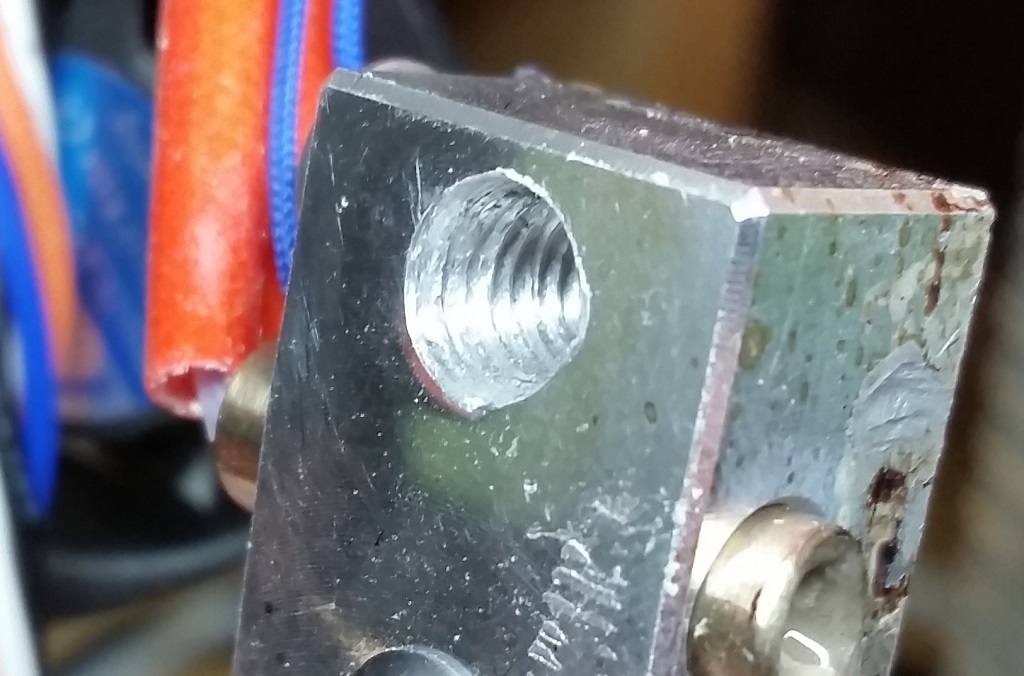

So the Heater screw thread was damaged like this:

However, using a bolt, inserted from Nozzle side, first using a spanner, and insisting until I was able to freely screw/unscrew by hand, I was able to have a decent screw thread on the heater:

The Heatsink screw thread looks ok, appart from the additional metal sticked to it.

Right now I'm trying to remove most of the metal using a cutter blade, staying in the screw thread direction, but it's not very efficient. I don't want to use a nuts until the screw thread is partially clean, the nuts does not have a good grip yet and I want to avoid additional damage.

I'm like Jon Snow, I know nothing.

Re: Nozzle Body stuck

Christophe

I have a tap and die set that I used to use on my Chinese clone, but after a couple of cleans a new part is required.

I wonder if there was some thermal paste applied when being assembled. These can harden off with the heat and effectively glue everything together, but as far as I am aware, this is only required on the V6 between the threaded heat break and the heat sink.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

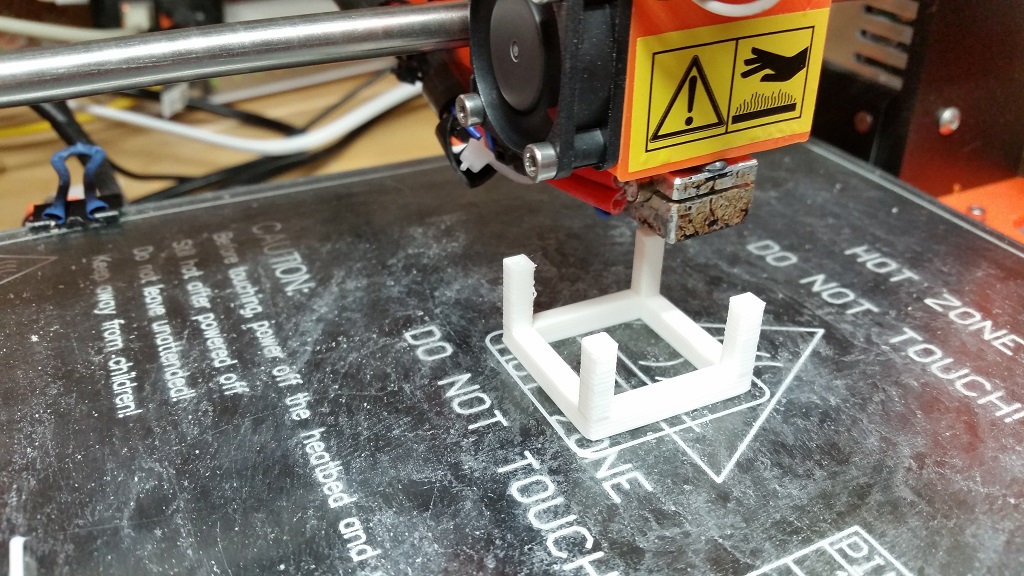

Re: Nozzle Body stuck

Well, using bolt and nuts to refine the screw threads was the way to go. I finally fixed the messed up screw threads and was able to have a decent reassembly. Now it's printing again, and without the annoying extruder sound I began to have.

However I don't know how many time I will be able to change PTFE tubes, sounds like I should consider to have a spare extruder in the future.

I'm like Jon Snow, I know nothing.

Re: Nozzle Body stuck

Christophe

Well done with the fix. As I mentioned, I have the V6 (originally as a spare) and after changing the tube on the Lite6, I decided to fir the V6. Since then I haven't had to change anything. The V6 has PTFE tube, but it is much shorter and higher up, so it does not get burned at these temps.

For me, the £43 spent has been very worthwhile by not having to take it apart.

http://e3d-online.com/E3D-v6/Full-Kit/v6-1.75mm-Universal

I also bought some other spares when ordering the nozzle; PTFE tube, fans, thermistor wire sleeve etc. Things that are good to have "just in case..."

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Nozzle Body stuck

I have just purchased the genuine Prusa I3 kit. Reading here the Prusa I3 kit comes with an E3D Lite, so we are unable to print the higher temp exotic materials as advertised without doing damage to the hotend, and changing the ptfe insert regularly, or have I got that wrong?

Nigel

Life is keeping interested and excited by knowledge and new things.

Re: Nozzle Body stuck

Hi Nigel

Josef has stated on these forums and on several occasions, that the maximum print temperature is 255 degrees, with which all the filaments can be printed, as advertised.

However, personally, I do not exceed 245 degrees when printing, but I have been able to print every filament type that I want to print.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Nozzle Body stuck

@Nigel

In my case, despite what I suspected, the PTFE tube was not damaged by heat (I print ABS at 255°C). However, I think I made a mistake while unloaded PET filament, having the extruder not enough heated. So there was some material stuck between the PTFE tube and the side of the heater body.

The PTFE was then misaligned with the nozzle, which explain my recent extrusion issues.

@Peter

Yes I'm considering going to E3D V6 as a replacement, since I reduced dramatically the life of my stock extruder.

Does something need to be adjusted to fully take advantage of this upgrade ? Is stock extruder holder fully compatible or should I plan some modified version to print ? And regarding Firmware, since I remember you stated that stock firmware is preventing going to temperature higher than 255 °C; should I compiled a tweaked version ?

I'm like Jon Snow, I know nothing.

Re: Nozzle Body stuck

Hi Christophe

The V6 is a simple swap-over with no adjustments required.

The firmware is now released if both Lite6 and V6 pre-compiled versions, so you only have to install the one with is right. However, even though I use a V6, I still run the Lite6 firmware as I just don't need the high temps (I print ABS @ 230 to 240 degrees).

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Nozzle Body stuck

Ahhh. OK, understood, apologies for any negative thoughts. Thanks for the replies. E3D is a good maunfacturer of hotends. I have just finished building my Original Prusa I3. Powers up ok and looks good. Calibration and tests Monday afternoon.

Nigel

Life is keeping interested and excited by knowledge and new things.

Re: Nozzle Body stuck

I have just purchased the genuine Prusa I3 kit. Reading here the Prusa I3 kit comes with an E3D Lite, so we are unable to print the higher temp exotic materials as advertised without doing damage to the hotend, and changing the ptfe insert regularly, or have I got that wrong?

Hello, you can print all the materials we advertise plus some more. Only material out of the temperature range I can think of right now is PC and we don't advertise this one. PTFE tube is consumable and we provide free replacements.

Re: Nozzle Body stuck

Thanks for the reply Josef. I understand and apologise for any doubt. I calibrated and tested my I3 today from yourselves. Fantastic test prints, especially the vase 🙂 I'm a happy person. 😀

Nigel

Life is keeping interested and excited by knowledge and new things.

Re: Nozzle Body stuck

Hello, you can print all the materials we advertise plus some more. Only material out of the temperature range I can think of right now is PC and we don't advertise this one. PTFE tube is consumable and we provide free replacements.

Hi Josef,

I bought some in a local store, so it's ok for me. the price of PTFE is just insignificant but the additional shipping cost is then not rational.

But may I suggest to add some PTFE replacement in the next printer kit packages ? It would make some sense 🙂

In addition, in your opinion, what could be the root cause of what happened to me ? I just want to be sure not to do the same mistake again.

[edit: Sorry for the misunderstanding, using "ridiculous" in french have just the opposite meaning]

I'm like Jon Snow, I know nothing.

Re: Nozzle Body stuck

I have bought some spare ptfe tube direct from E3D. It costs pennies.

Nigel

Life is keeping interested and excited by knowledge and new things.

Re: Nozzle Body stuck

Nigel

Likewise, I prefer to buy from E3D (usually at the same time as spare fans and nozzles) as at least I know that I am getting the right tubing.

There are various grades of PTFE tube available on places like eBay and I don't think I could trust I was getting the right stuff there...

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…