[MK2S] X axis smoothrod deep scar / scratch

I did assemble my mk2s about a week ago, took my time and built it as precise as I could, all the axes where moving as smooth as a porn stars ass, little to no force required, also cleaned and greased up all the bearings.

The selftest did report that all the axes were perpendicular.

According to astroprint my printer has run for a total of 27h only.

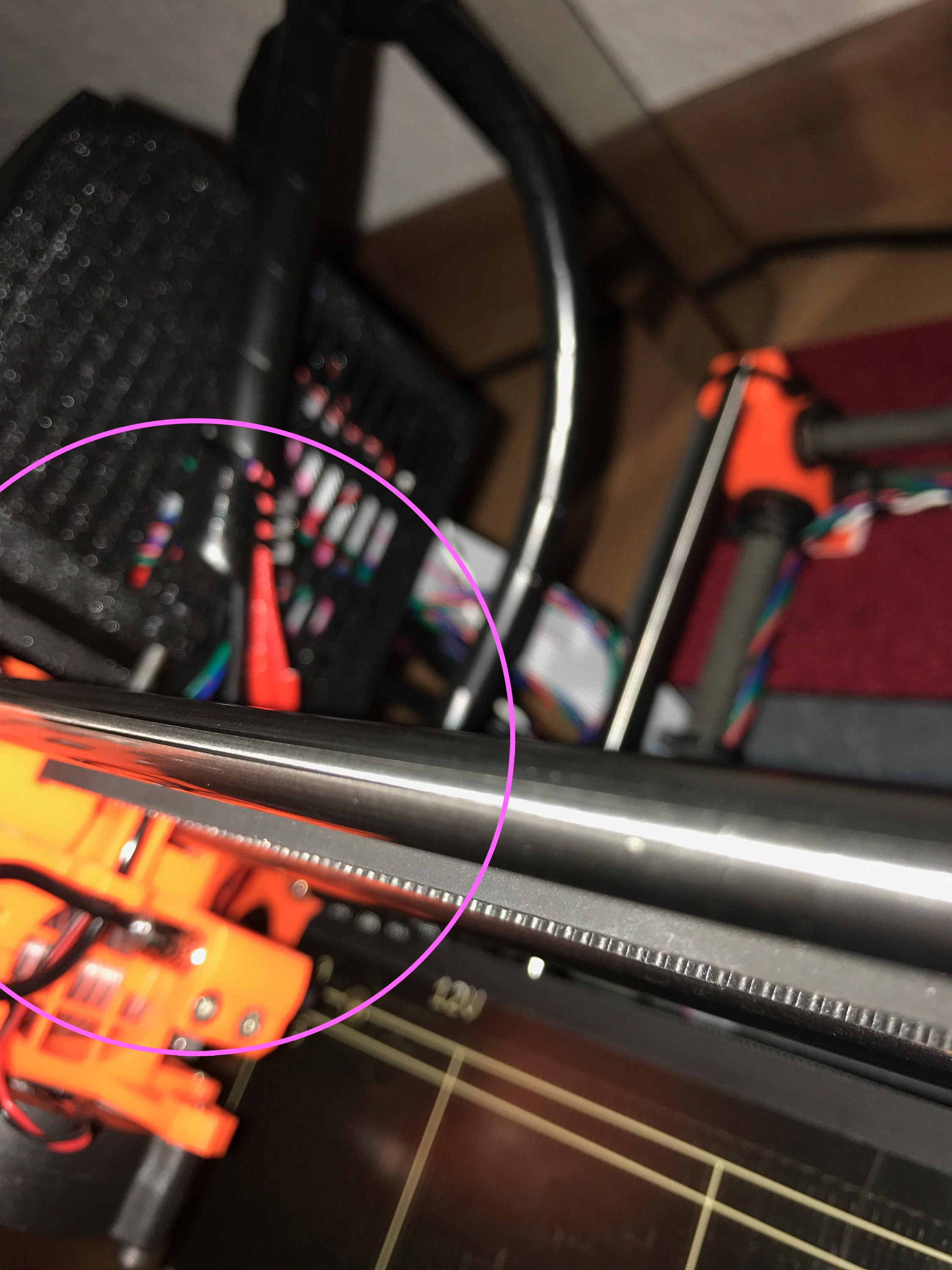

Now yesterday I started to hear a strange rattling / grinding noise when the X axis moved, I did cancel the print and inspected the printer. I noticed a deep scar on the lower smoothrod (the one with only one bearing) about of the width of a bearing ball and 5cm long. I guess the bearing gone bad..

Am I safe to replace the bearing and rotate it so that the line of balls don't go over the scar ? Maybe even use an igus drylin on the lower rod ?

Did anyone else had issues on the mk2s with bearings recently ? Afaik prusa upgraded the smoothrods and bearings..

Where could I get replacement quality smoothrods in europe already cut to length ?

Thank you very much for any help, much appreciated.

Re: [MK2S] X axis smoothrod deep scar / scratch

Post an image of the scratch.

When you move the bed by hand is it smooth? Maybe take off the bed and move each bearing by hand?

Re: [MK2S] X axis smoothrod deep scar / scratch

Its the X not Y axis, the bed is smooth, with the belt removed, it moves by gravity only.

The Scar on the x axis , well if i move the extruder by hand i don't hear any rattling sound and it is smooth, but when it prints it does make a rattling noise when it moves in the scratch / scar area.

I'll take a pic later on, when I'm home

Re: [MK2S] X axis smoothrod deep scar / scratch

hmmm.... maybe you've had a grain of sand... or another, very hard particle, inside one of your ball bearings.

i would recommend to disassemble the x-axis, remove the rod and blow out the suspicous ball bearing with compressed air.

maybe you can treat the rod with some very fine steel wool (0000 or 000), clean it up afterwards and lubricate it with some drops of motor oil (don't use oil for cooking, or ultra-fine valve oil for your trumpet) before reassembling the whole stuff.

dem inscheniör is' nix zu schwör...

Re: [MK2S] X axis smoothrod deep scar / scratch

I really think the bearing was faulty, my other hobby is rc model flight, mostly helicopters, so I'm used to build mechanical stuff. I applied the same build techniques on the prusa. Maybe it's overkill, but for bearings I do the following :

- Clean with a degreaser like brake cleaner (bremsenreiniger ?)

- Give them 3 cycles with an ultrasonic bath with distilled water

- Blow them out with compressed air.

- relubricate with bearing oil to avoid corrosion

- apply synthetic grease (Mobil1, the red sticky stuff)

for the rods, I also did clean them with the degreaser and lubricated with teflon oil.

And ofc metal to metal connections are secured with thread loc.

I use the same on model helicopters with up to 1.6m rotor disk,where high rpm and torque is applied to the moving parts, no issues so far.

I will disassemble the X carriage and inspect the bearing, but it will go to the bin anyway and will be replaced, I have some lm8uu and igus bearings at hand,I just built the printer as is for the initial build. Also got some polishing cloth with 6-8-10-12-15k grid available to polish the defect rod with.

@Jeff, btw I saw your awesome MK2X build, really a piece of Art. Where did you source the bearings and smooth rods for it ? any retailer in germany ?

wäre Dir sehr dankbar für die Angabe deiner Bezugsquelle. Da ich die Gleitwellen sowieso ersetzen werde.

Re: [MK2S] X axis smoothrod deep scar / scratch

...@Jeff, btw I saw your awesome MK2X build, really a piece of Art. Where did you source the bearings and smooth rods for it ? any retailer in germany ?

you've got a pm.

dem inscheniör is' nix zu schwör...

Re: [MK2S] X axis smoothrod deep scar / scratch

Hi,

this problem i had few days ago.

I own a MK2S that worked flawless untill 2 days ago, than started to make a noise and vibrating. After a double check i found the problem comes from one bearing of Y axies (heatbed). It ruined my smooth rod with deep lines scratches. now i stopped to use it and i wrote an email to the technical servis of Prusa Reserch. I don't know if they use a better smooth rods or better bearing with MK2S version.... but i only used my printer for 4 days total time printing. Also i pay attention to install the bearing with the u-bold, i didn't tight too much! i think also my bearing was faulty and the smooth rods are easy to scratch, it means they are not good quality as Prusa Reserch want to describe.... Still waiting for an aswer from them...

Re: [MK2S] X axis smoothrod deep scar / scratch

Hi,

I have the same problem..there are scars and also some grooves wide as the balls from the bearing. I believe that the rods are too 'soft'. My former chines printer didn't have this problem after hundred of hours of printing. It is very strange...

Re: [MK2S] X axis smoothrod deep scar / scratch

Same problem here, not even 1 print done. Several scratches appeared when calibrating. I have taken the x axes and checked the bearings, cant find the issue.

Someone had some luck or answer from Prusa?

Re: [MK2S] X axis smoothrod deep scar / scratch

I also had scratches and noise from a bearing after about a month, in my case it was the single Y axis bearing. I did a similar prep in my build with brake cleaner, blowing out with compressed air, then packing with a silicone grease.

I went the replacement route and just ordered Misumi bearings and rods all around. So far so good. They roll very nicely and are quite a bit quieter than the stock bearings.

Thread with part numbers: http://shop.prusa3d.com/forum/original-prusa-i3-mk2-f23/replacement-bearings-recommendation-t2085-s90.html