Failed prints - with patterns

Hi,

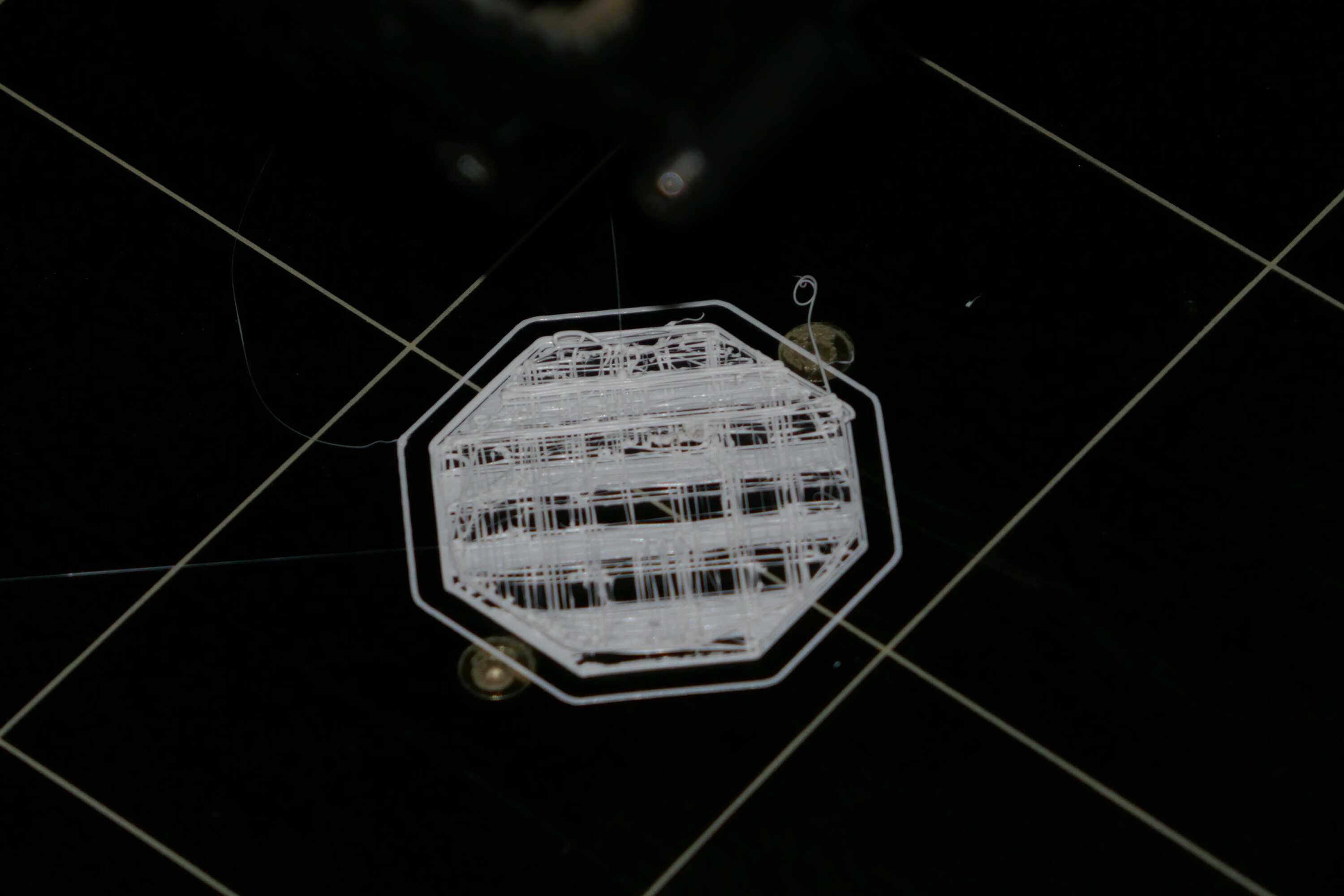

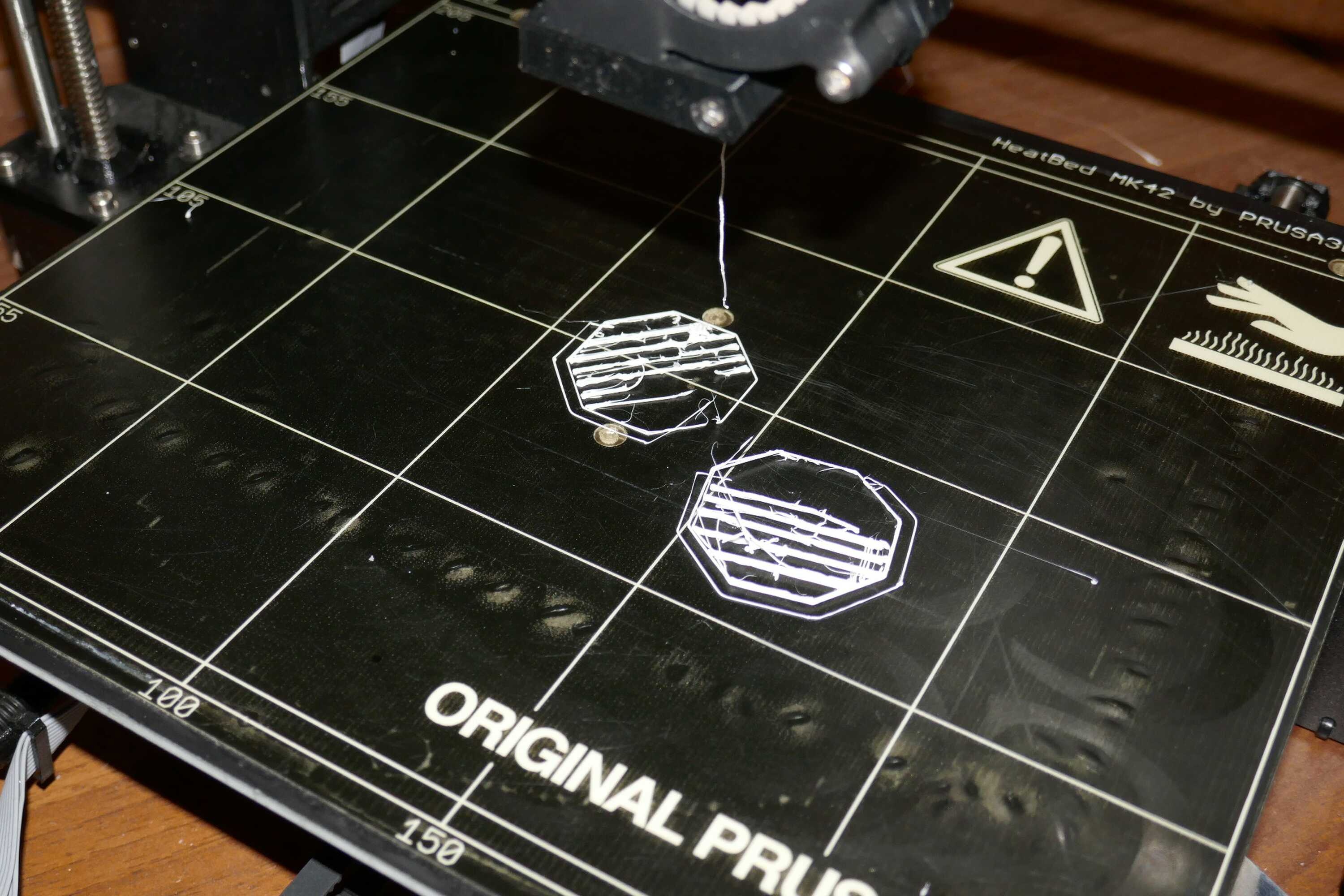

I cannot print anymore. My prints, both in PLA and PETG (with the settings which worked) look now like these:

or another one

It is obvious the pattern between the lines. Of course, the octagon is supposed to be filled.

[*] V2Calibration.gcode prints (somewhat?) ok. Tried here with different values for Live Adjust Z.

[*] When I extrude the filament in the air via Settings \ Move Axis \ Extruder works ok.

Trying to push"by hand" the filament doesn't help.

What can I do?

Re: Failed prints - with patterns

This looks like a classic Live Adjust Z setting problem.

See the excellent thread "Life Adjust Z - my way" make sure to read the first 6+ pages and get V4 of the cal file.

http://shop.prusa3d.com/forum/prusa-i3-kit-building-calibrating-first-print-main-f6/life-adjust-z-my-way-t2981.html

The method I use is as follows:

1) Get it roughly correct.

a) Set Live adjust Z = 0.00. Make sure PINDA is above nozzle tip by <1mm but above.

b) Do a Calibrate Z. (Head must be clean of drips and lumps).

c) Do a Home. This leaves the head at Z=0.15mm

d) Use Setting -> Move Axis X and Y to get in the approx center of the print space. DONT TOUCH Z.

e) Put a piece of printer paper under the head. Printer paper is approx 0.1mm

f) Wiggle the paper while adjusting "Live Adjust Z" (in settings) until the paper just starts to drag on the paper.

g) Back off a bit (50) on the Live Adjust Z"

2) Get it dialed in real well.

a) Print using "Calibration_surface_PLA_75x75@200um_v4.gcode" found in Jeff's "Life Adjust My Way" Thread

b) Repeat until you have a nice test print - all stuck together and one nice clean sheet.

This takes a little while, but is worth the effort. Once the first layer is good - the rest follows.

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…

Re: Failed prints - with patterns

Ok - got it. Extruder problem. The brass pulley of extruder get worn asymmetrically. That's why the extrusion is done „in steps”. See here:

Also, I did the calibration outlined here: http://shop.prusa3d.com/forum/prusa-i3-kit-building-calibrating-first-print-main-f6/extruder-calibration-t2033.html which confirmed clearly that the extrusion is done in steps which means that the pulley is worn (or something else?).

Most probably the 1,5 kg of Glow filament printed lately is to blame.

0. Has someone other solutions?

1. If this is the solution, from where can I buy a new hobbed pulley made from a better material? (Stainless steel is preferable).

2. Also, does someone knows the dimensions of Prusa's hobbed pulley?

3. Can I buy a pulley of different dimensions?

Re: Failed prints - with patterns

I can only answer a few questions of the top of my head.

Replacing the pulley is your best bet. If you change dimensions, you will need to calibrate your extruder (how many steps get how much filament - lots of threads here on how to do that.) If you change drastically, the fine details may or print speed may be affected. i would stay at this size, unless you are very experienced and know what your intent is.

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…

Re: Failed prints - with patterns

I can only answer a few questions of the top of my head.

Replacing the pulley is your best bet. If you change dimensions, you will need to calibrate your extruder (how many steps get how much filament - lots of threads here on how to do that.) If you change drastically, the fine details may or print speed may be affected. i would stay at this size, unless you are very experienced and know what your intent is.

Fully agree. From where to take it?

Re: Failed prints - with patterns

Any place that sells the 3ED-V6 hottend should have the HobGoblin, just get the correct size:

http://e3d-online.com/Mechanical/Bowden

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…

Re: Failed prints - with patterns

Any place that sells the 3ED-V6 hottend should have the HobGoblin, just get the correct size:

http://e3d-online.com/Mechanical/Bowden

...and what is the correct size?

Re: Failed prints - with patterns

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…