extruder skipping, nozzle depth issue?

Hello,

I have a i3 mk2s kit, that has been printing fine for a while and started acting up lately, the extruder making skipping noises.

I tried tightening and loosening the idler making no change. Messed with the temperature, no change either. Slowing down the print, no change either. The issue is the same with PLA, PET and ABS. Then I tried disabling retraction and the problem disappeared for PET and ABS, and for PLA it still happens but not as quick.

This seemed to point towards a badly mounted nozzle or teflon tube causing clogging, so I started investigating. Unfortunately I have no close up picture of the nozzle/extruder at this point. I quickly found out if I unloaded the filament, cut off a piece and then loaded again it started printing again.

I removed and replaced the nozzle, but I couldn't get it in completely. I seem to remember it was not completely in before but again, I have no picture of it.

I then decided to try the hardened steel nozzle instead and it got in, but again stopped going deeper at the same point. I then applied some more force and it started moving again, but I guess I just destroyed the heat block threading as it turns freely but doesn't move any deeper :p

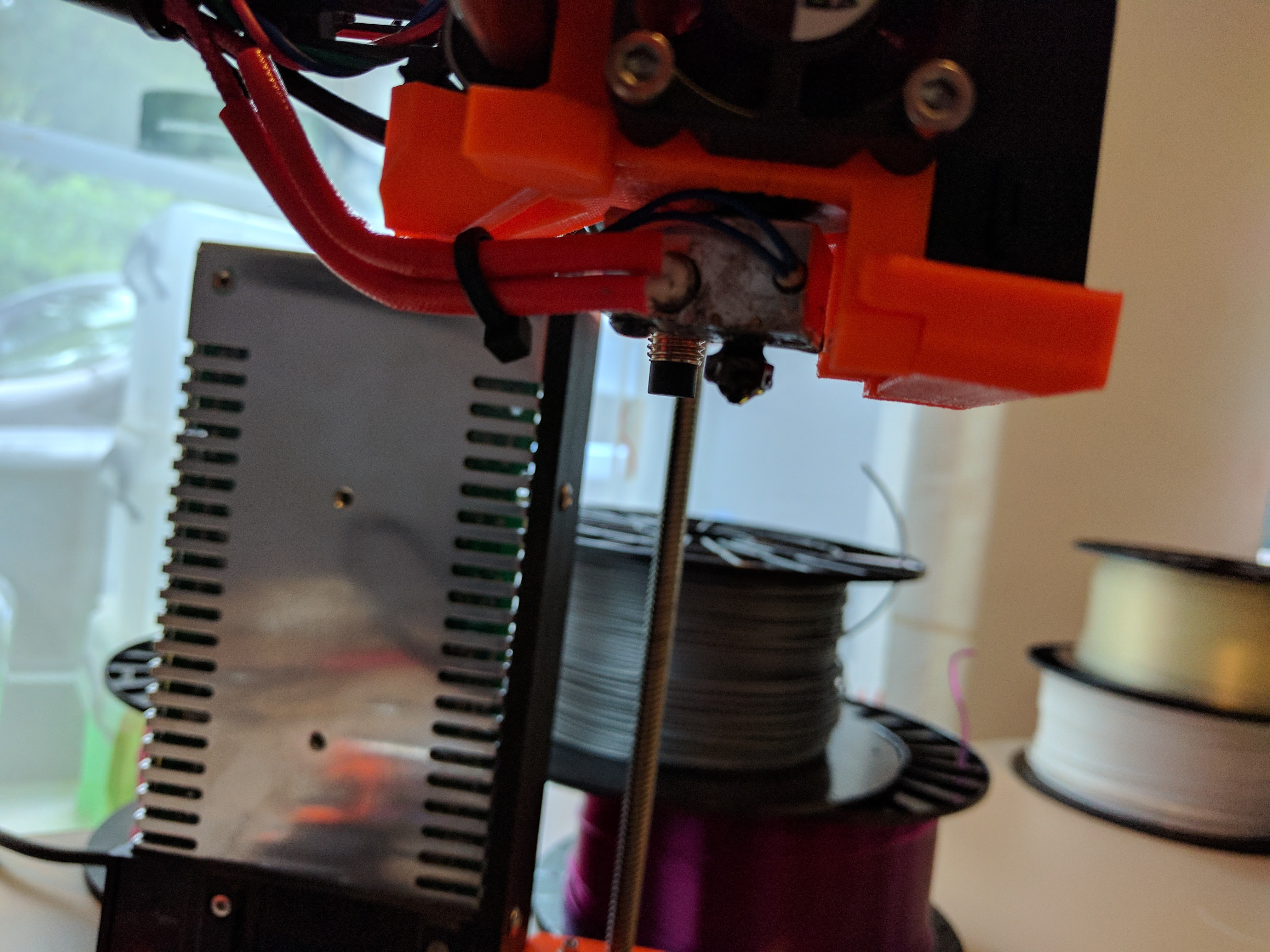

See attached picture for the nozzle and its distance from the heater block.

See second attached picture for the filament when it is unloaded after being clogged. (This picture is a bit unclear, sorry about that :p)

At this point I think I'll just have to buy a new hot-end and make sure the nozzle is correctly mounted from the start. I don't see it in the prusa shop though.

Luckily for emergency printing I can still print fine with PET (or ABS).

Re: extruder skipping, nozzle depth issue?

💡

first: I don't think that you have to buy a complete new hotend.

when working at the hotend, replacing a nozzle or heatbreak, you have to do this when the hotend is heated up to approximately the maximum temperature you can reach (300°C will do).

➡ thomas sanladerer has a video at youtube that explains how to assemble (and disassemble) a hotend. take in mind that the best way to do this is with the hotend fixedn in a vice, while the cables for the heater cartridge and the thermistor are still attached to the rambo (so that you can control the temperature).

and yes, at your "reassembled" hotend your nozzle peeks far to much out of the heater block (and it's probably leaking).

by the way: copper paste is quite handy when reassembling the whole hotend. you can get such stuff at shops for car parts.

➡ have a look at this thread, where the hotend of our prusa i3 mk2(s) is described.

➡ and do a search for "chamfer" and ptfe tube at this forum, if you want or need to replace the tube.

second: if you still think that you need a new hotend, you can get it from e3d-online or at the prusa shop (3D printer parts -> MK2 spare parts). to get access to this part of the shop, you need to be a registered customer and have to chat with the sales team because they need to enable the access manually for each customer.

but take a seat before you look at the prices of the replacement parts at the prusa shop (and shipping costs) :?.

💡 furthermore: to avoid clogging, it's very important that the extruder fan (the tiny 30x30x10mm fan at the left side of the extruder body) is always running at full speed, as soon as the hotend temperature reaches 50°C. it's essential that the coldend (the upper part of the hotend) cools down below 53°C, otherwise the filament would melt to high up into the heatbreak.

dem inscheniör is' nix zu schwör...

Re: extruder skipping, nozzle depth issue?

Thanks for the reply,

Yes, I've heated the extruder to 260C (not 300C) to remove/replace the nozzle.

it looks like I can buy a new heater block separately, e.g. this: http://e3d-online.com/E3D-v6/Metal-Only/V6-Block-Sock-Kit which is reasonably priced.

It should be able to fit it to the remainder of my existing extruder (nozzle & cooler top part).

Re: extruder skipping, nozzle depth issue?

Hello,

FYI, I replaced the heater block and the nozzle by copper replacements from E3D, making sure all is mounted correctly now. I also added their silicone sleeve while at it.

The printer prints really great again now. Actually I have to lower the temperature setting for PLA about 10C presumably because of the Copper and the sleeve, also cooling down takes longer :o. The temperature is more stable though!

Cheers, Joost