Clogged cold end, partially solved

Ok, so, apparently to confirm that I make dumb mistakes, I had the horrible idea of increasing the retraction length during a big print.

The result of that was a completely clogged extruder, with the filament very strongly stuck in the cold end.

Long story short, I disassembled the extruder, but was unable to get the heatsink out of the plastic (maybe my teflon tube is stuck to it like I saw in a different thread?). I didn't give up though and I still managed to get to the point where I was able to clear the plastic out of it with a drill bit.

I put it back up together, and it's printing relatively great, but I suspect I have either damaged something with the drill bit or caused some other problem.

The extrusion seems slightly irregular. I can't seem to capture it well enough with a picture, but I think the best way to describe it is that the thickness of the extruded lines is not constant, and for example when printing two solid layers, you almost end up with a grid pattern rather than solid plastic.

I haven't tried playing with the extrusion multiplier to see if it helps, but I wanted to hear ideas before trying anything else. The printed parts are still pretty usable, just not as high quality as before this happened.

Thanks in advance for any help.

- Gab

Re: Clogged cold end, partially solved

Pretty sure a new nozzle is in your future, luckily they are not expensive. Probably should order it now because even if you can resolve your issue it is good to have a spare.

I had the exact same thing happen to me on a different 3D printer. For me the drill bit altered the hole causing flow issues.

There is a chance that the nozzle hole is okay and you just need to clear it. Have you done the atomic method of cleaning? You could try some cleaner from eSun but at this point it just better to replace the nozzle. I spent two weeks playing around with trying to resolve the issue I was having when I gave in and order an upgrade nozzle from Amazon that arrived the next day and was back up printing.

If you get a new nozzle, you may see if you can get a nickle plated brass nozzle which will prevent jams.

Re: Clogged cold end, partially solved

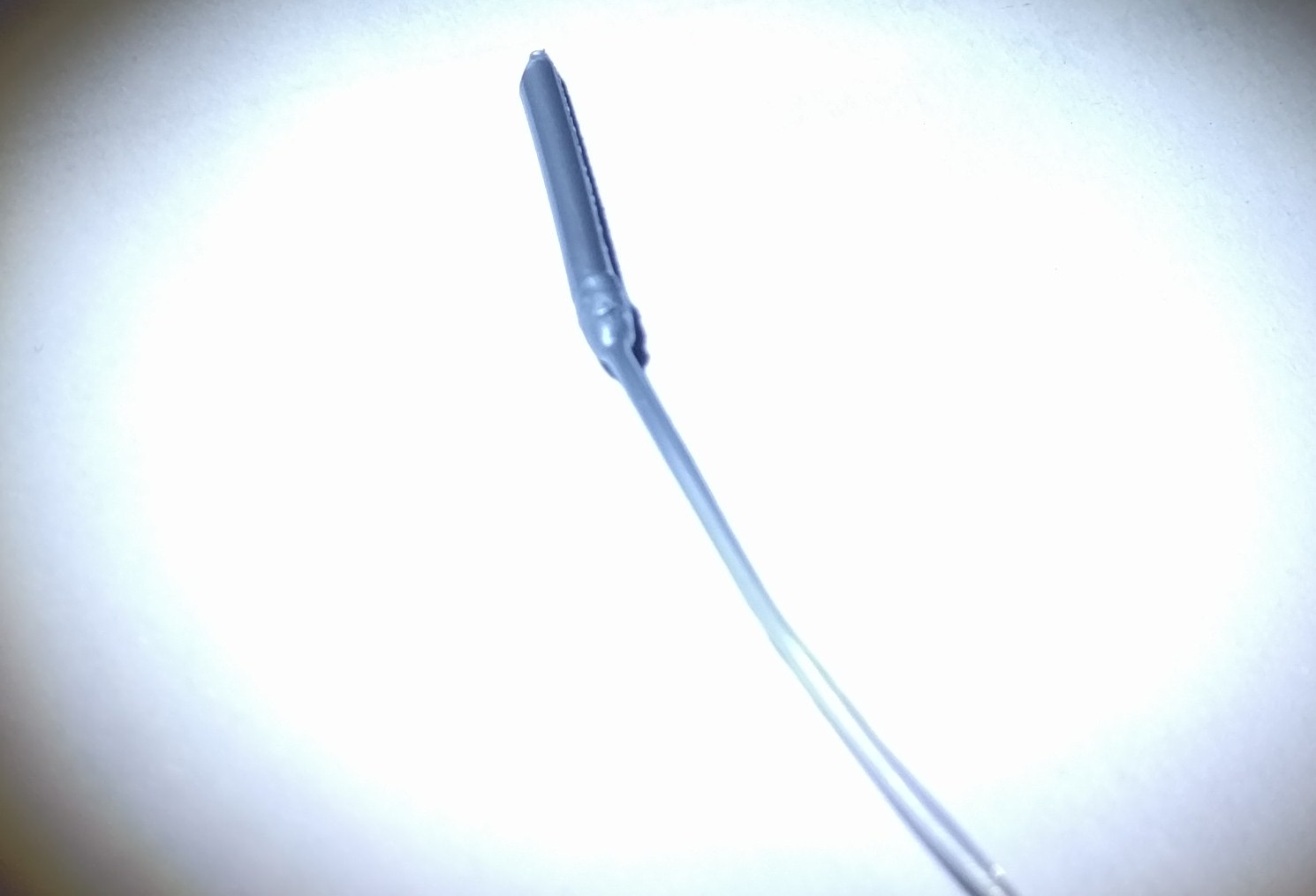

Sometimes you can pull out a good cast of the inside of the hot-end and nozzle.

Any old bits of filament still inside the hotend and/or nozzle come out along with the filament cast.

Like this: When the extruder is at the filament specific temperature, turn the nozzle temp to zero and loosen the tensioning screws on the idler while it cools. Then, when the hotend is at about 120C, pull on the filament by hand.

Another way to clean it is to print with a bit of carbon fibre laced filament, but a standard (i.e. not a hardened nozzle) will soon be ruined by that.

The other day I managed to clear a blocked heat break (like you had from too much retraction) by stopping the heatsink fan with a finger for a minute, then pushing filament in manually from the top (idler tensioner screws loosened).

Re: Clogged cold end, partially solved

I will try the cold pull. I do want to get spare nozzles anyway so I'll probably go ahead and do that and see if it makes a difference.

What should I search for on Amazon? Just E3D V6 nozzle?

- Gab

Re: Clogged cold end, partially solved

Looks good, can you see any contaminants stuck in the cast?

Or does it look deformed from drilling the nozzle?

Re: Clogged cold end, partially solved

No contaminants, but it's not smooth at the tip, even though I haven't touched the nozzle with the drill.

In any case I ordered replacement nozzles, will see if it makes a difference once they arrive.

- Gab

Re: Clogged cold end, partially solved

If a drill bit and/or steel wire has not been used, then it is worth giving the eSun filament cleaner a try.

Re: Clogged cold end, partially solved

Looks pretty good. I think at this point if you want less stringing you need to look at different vendors / colors of PLA.

Re: Clogged cold end, partially solved

The top layer looked much better before the "accident". Now there are gaps. Also the gears pictured above don't move at all.

Maybe it's something else but it looks like inconsistent extrusion to me. Anyway, I'll see what happens with a new nozzle; it's still "good enough" so if I can't fix it it's not the end of the world.

- Gab