Calibrating extruder

I have watched toms video and I understand the majority of it, but I am stuck on the gcode part.

My printer is 5mm short of 100mm I extruded.

But I don't understand where to get the steps per mm.

I entered in M503, but I get this in pronterface:

SENDING:M503

echo:Steps per unit:

echo: M92 X100.00 Y100.00 Z400.00 E161.30

echo:Maximum feedrates (mm/s):

echo: M203 X500.00 Y500.00 Z12.00 E120.00

echo:Maximum Acceleration (mm/s2):

echo: M201 X9000 Y9000 Z500 E10000

echo:Acceleration: S=acceleration, T=retract acceleration

echo: M204 S1500.00 T1500.00

echo:Advanced variables: S=Min feedrate (mm/s), T=Min travel feedrate (mm/s), B=minimum segment time (ms), X=maximum XY jerk (mm/s), Z=maximum Z jerk (mm/s), E=maximum E jerk (mm/s)

echo: M205 S0.00 T0.00 B20000 X10.00 Y10.00 Z0.20 E2.50

echo:Home offset (mm):

echo: M206 X0.00 Y0.00 Z0.00

echo:PID settings:

echo: M301 P40.93 I4.88 D86.08

echo:Retract: S=Length (mm) F:Speed (mm/m) Z: ZLift (mm)

echo: M207 S3.00 F2700.00 Z0.00

echo:Recover: S=Extra length (mm) F:Speed (mm/m)

echo: M208 S0.00 F480.00

echo:Auto-Retract: S=0 to disable, 1 to interpret extrude-only moves as retracts or recoveries

echo: M209 S0

echo:Filament settings: Disabled

Which of all that is the steps per mm I need?

Then I take steps per mm x 100/ filament extruded? This is the new steps per mm?

M92 E (steps per mm)

M500

Is that all there is to it?

Will this be permanent for my printer or is there some value in my Slic3r I can adjust to compensate?

Is there an easier way without using gcode?

Extrusion multiplier in slic3r?

Re: Calibrating extruder

Your current settings are:

...

echo:Steps per unit:

echo: M92 X100.00 Y100.00 Z400.00 E161.30

...

So the setting for the Extruder is: E161.30

The value you want is 161.30 x 100 / 95 = 169.79

In pronterface, enter:

M92 E169.79

M500

Instructables article here: http://www.instructables.com/id/Calibrating-your-3D-printer-using-minimal-filament/

This info should be on Prusa's website somewhere (if somebody knows where, please post).

-Kevin

Re: Calibrating extruder

Hello Brent,

I came across this which explains it well for the X/Y axis: http://www.thingiverse.com/thing:2050876 , and it's basically the same thing for the Extruder (or Z axis).

As Kevin said, M92 X100.00 Y100.00 Z400.00 E161.30 is your steps (for X/Y/Z/E), and E161.30 would be your extruder steps. As mentioned:

100 (mm expected filament to extrude) / 95 (mm actual extruded filament) = 1.0526

1.0526 * 161.30 = 169.7895 (or 169.79) for your new M92 Enn value: M92 E169.79

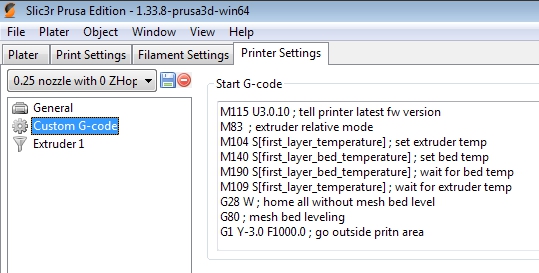

You can add this to your Slic3r settings under Printer Settings >> Start G-code:

I'm not sure if there's a best place to put this, but maybe at the end?

If someone notices something wrong in my reply, please let me know.

Thanks

Re: Calibrating extruder

Correct me if I'm wrong, but I think M500 permanently writes the values in EEPROM, so adding the M92 in the start Gcode in Slic3r should not be necessary.

Having said that, since the extruder calibration strongly depends on filament, I personally think using the extrusion multiplier setting in Slic3r would be a better choice.

Re: Calibrating extruder

Correct me if I'm wrong, but I think M500 permanently writes the values in EEPROM, so adding the M92 in the start Gcode in Slic3r should not be necessary.

Having said that, since the extruder calibration strongly depends on filament, I personally think using the extrusion multiplier setting in Slic3r would be a better choice.

Putting it in the Gcode, to me , is preferable. When upgrading the firmware you won't have to remember to save the correct e steps back to the firmware.

Also, the e-steps calibration should have nothing to do with the material you are using. It strictly measures that 100 mm of filament gets pulled off the reel when requested.

Re: Calibrating extruder

Also, the e-steps calibration should have nothing to do with the material you are using. It strictly measures that 100 mm of filament gets pulled off the reel when requested.

Richard, not quite. Filament hardness will ever-so-slightly affect the 100mm feed. That should be adjusted for bay changing the feed tension though.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Calibrating extruder

Also, the e-steps calibration should have nothing to do with the material you are using. It strictly measures that 100 mm of filament gets pulled off the reel when requested.

Richard, not quite. Filament hardness will ever-so-slightly affect the 100mm feed. That should be adjusted for bay changing the feed tension though.

Peter

Yeah, that's why I said should have nothing to do with it. The best example of that is with extremely flexible materials, which I still can't get to print reliably.

Re: Calibrating extruder

I'd also like to know where to put this. I cannot seem to find the answer either.

Some say it has to be added to the tooling code but I have nothing in there. So where would this go in the picture I attached?

Re: Calibrating extruder

Thanks for the replies everyone I really appreciate it.

My understanding is you would enter the Gcode after the first line . Right after the line that says firmware version.

Maybe someone will chime in and verify that.

Re: Calibrating extruder

Yes, after the firmware version is fine.

Re: Calibrating extruder

Ok Guys, I placed it after the firmware version.

I also noticed that my Firmware version was 3.0.9 and not the 3.0.10 that it is on.

I simply changed it to "10" on all the configs. Is that ok?

Lastly, I apologize for taking over the thread but this is hopefully helping the OP as well.

Jon