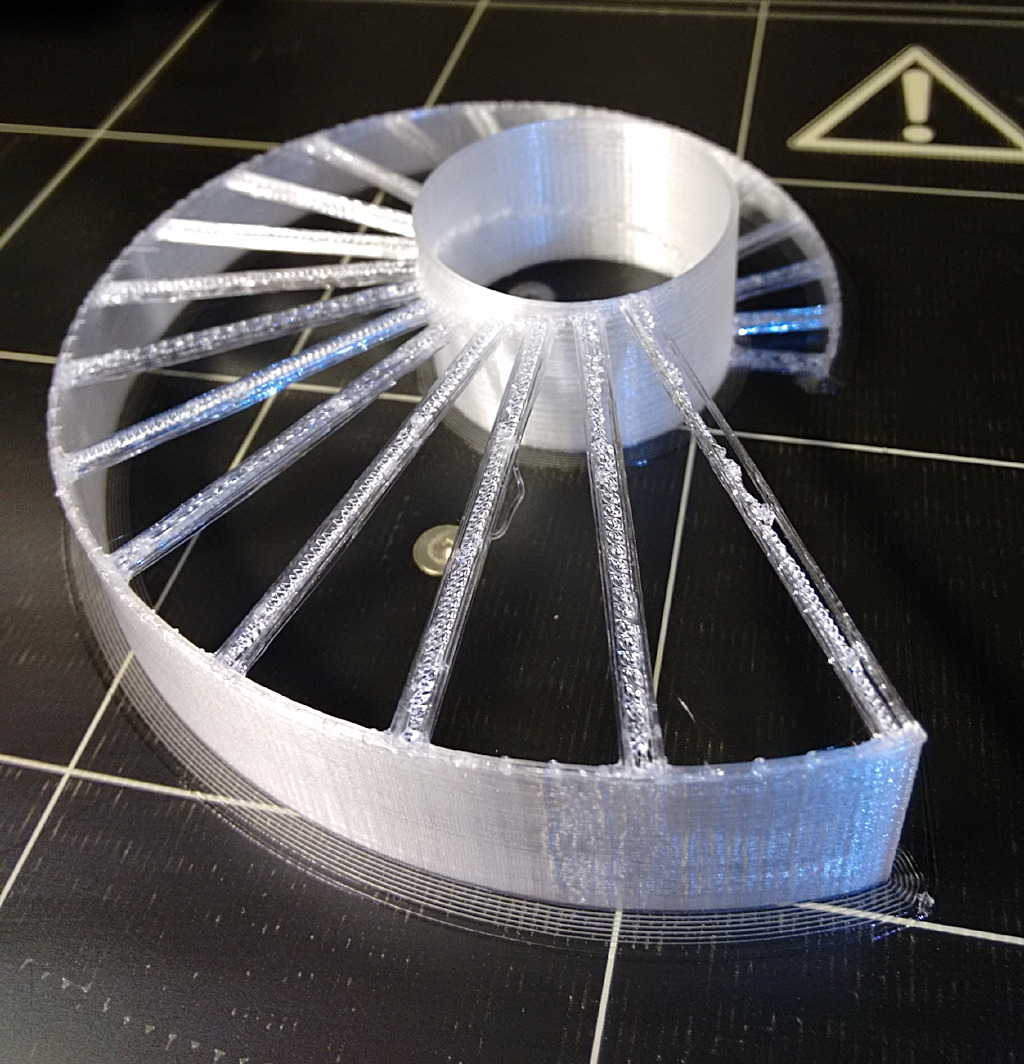

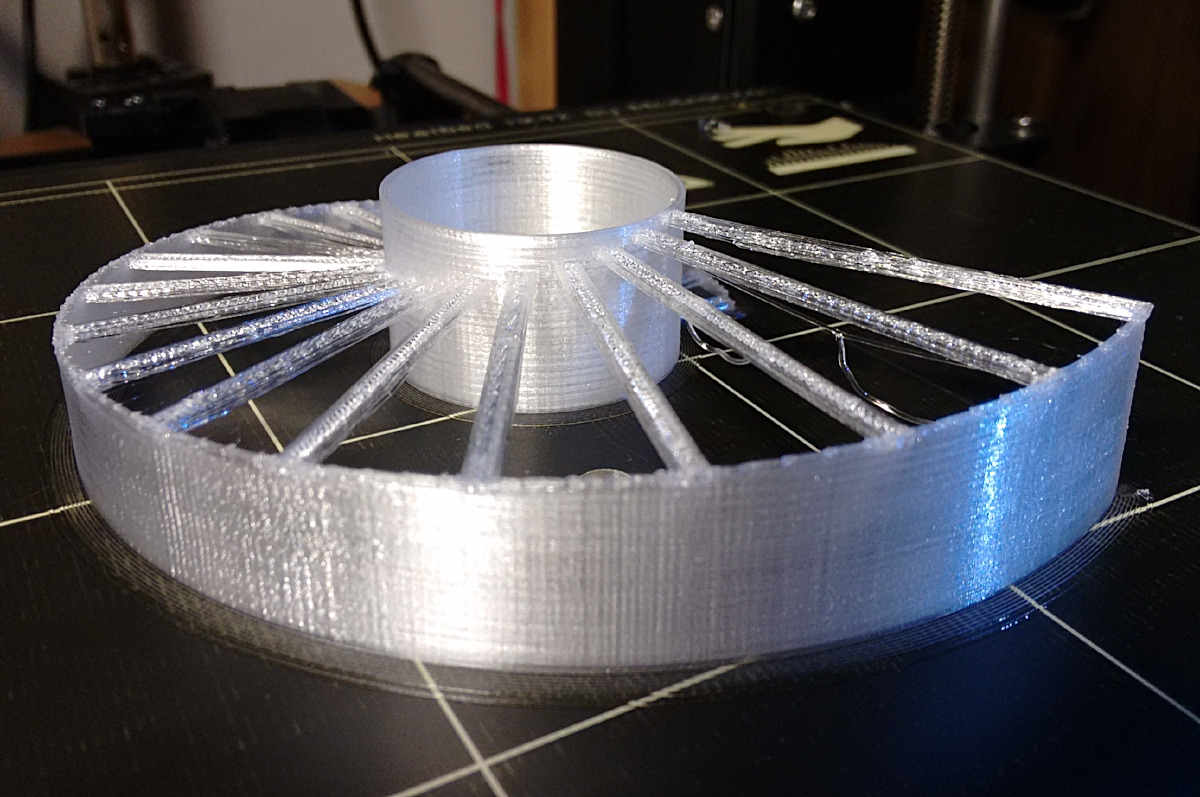

Bridging Test, eSun PETG

Who could know that it worked out so good with no tweaking. And also produces such a nice object 😮 😯 😆

Biggest Bridge is 5cm. Not sure if one can expect more without optimizing? What is the key? I am not sure if I should speed the bridges up or use less extrusion? Maybe I just wait for a real world bridge in an object before taking the time to optimize.

Carsten

My Prints: https://www.prusaprinters.org/social/15695-carsten/prints

My Employer: https://make-magazin.de

Re: Bridging Test, eSun PETG

In my opinion PETG is hard to bridge with because it's less rigid and doesn't shrink.

A material like PLA bridges nicely because it's pretty rigid as it comes out, and when you tack it off to the other side, it shrinks a little and helps tighten things up.

That said, in your example, your failure is that the bridging wasn't recognized by the slicer. The original perimeters were bridged, but then it went to infill and it turned into a mess.

The fix to try for that is to increase your perimeters. Basically make every one of those bridges all perimeters so it shoots straight across.

Re: Bridging Test, eSun PETG

Fail? Only the longest two have some stings falling trough?

And I can easy see while printing that PETG is shrinking. The perimeter hangs a bit after pulling and then cooled it lifts up nicely.

Carsten

My Prints: https://www.prusaprinters.org/social/15695-carsten/prints

My Employer: https://make-magazin.de

Re: Bridging Test, eSun PETG

Uh, well, I wouldn't exactly call it a success. Like if that were a customer print, I wouldn't give it to him and exclaim, "The print was a success!"

PETG shrinks a little, but not nearly as much as PLA.

Oddly, that property means PETG is better at overhangs and worse at bridges.

And then PLA is better at bridges and worse at overhangs (because the shrinkage causes the overhangs to curl up).

Re: Bridging Test, eSun PETG

For a customer i would print with Support and .2 layers.

Carsten

My Prints: https://www.prusaprinters.org/social/15695-carsten/prints

My Employer: https://make-magazin.de