Weird print fails

I've had my mk2 since Christmas and seen my share of fails but mostly been doing OK. Recently, however, something took a turn for the worse. One morning as I came down to check on an overnight print, I found the hotend stuck to the print and the entire heat block encased within a big blob of PLA!

So I took out my hot air gun and pried away the plastic. The thin thermistor wires broke in the process (their insulation tubes were solidly gooped inside the plastic)! but enough of them was left for me to tack on some new wires and I was able to clean up the rest of the hotend so it seemed to be working again.

Then a few days (and several prints) later, the same thing happened again. The heat block was "welded" to the catastrophically failed print. This time, the thermistor wires broke inside their metal tube so I've ordered a new thermistor from Prusa. And while I was at it, I ordered a new PTFE tube as well.

But what's more important than the new parts and the down time, is WHY? Does anybody have any clues to what may be the cause? I've seen prints tear loose from the print bed and drag along under the hotend but in these two new failures, the printed objects were still solidly stuck to the print bed and the print carriage must have been struggling pretty hard to try and tear loose!

One possible additional clue (although it could be completely unrelated): During the time between the two big fails, I noticed a lot of "tadpoles" of plastic around the printer. Small blobs, 1-2mm thick and 3-5mm long, with a "tail" of very thin PLA at one end. I first thought they were some kind of overextrusion (and in a very broad sense I still suppose they must have been) but they were not attached to the print. Is it possible that I may have had some kind of "leak" where molten plastic was escaping sideways out of the hotend?

I've only been using PLA. Most recently some reasonably priced no-name from Swedish DIY/Hobby chain Clas Ohlson.

Any ideas?

/Torsten

Re: Weird print fails

very likely that your hotend was leaking. this happens if you assemble the heatend when it's to cold. especially the heatbreak and the nozzle need to be tight, that's why you have to screw the parts together at about 300°C in the way that the (clean) heatbreak and the (clean) nozzle "kiss" each other in between the heater block.

so if you've accidentially unscrewed the heatbreak and/or the nozzle from the heater block during the assembly of your printer, that might probably have led to the leakage.

or if you've changed the nozzle while the temperature of the heater block was lower than approximately 250°.

dem inscheniör is' nix zu schwör...

Re: Weird print fails

Ah! Thanks @jeffjordan that would indeed be an explanation.

From what you say, it sounds likely that the "tadpoles" were merely a benign symptom of the same root cause (=leakage!) and the more serious issue would have been leaking plastic building up around the heat block until there was enough for it to catch on the printed object.

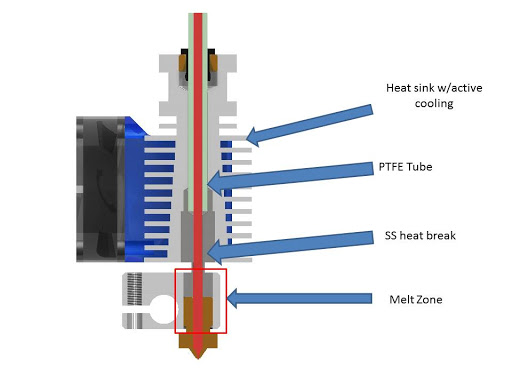

A follow-up quetsion: In the video about replacing the Teflon tube ( ) at about 3:00 in, Dave says that the tube should protrude about 1mm from the heat brake. But the old tube I have isn't that long and there's something preventing it from going that far in. Is that video for some older version of the printer or have I got something stuck inside the heat brake (a piece of the Teflon tube)?! It looks to me like the "waist" between the threaded part and the body of the heat brake is much too narrow for the Teflon tube to go inside.

When you say that the heatbrake and the nozzle should "kiss" inside the block, should they be touching metal-to-metal or should there be a bit of the Teflon tube squished in-between?

/Torsten

Re: Weird print fails

...

When you say that the heatbrake and the nozzle should "kiss" inside the block, should they be touching metal-to-metal or should there be a bit of the Teflon tube squished in-between?

/Torsten

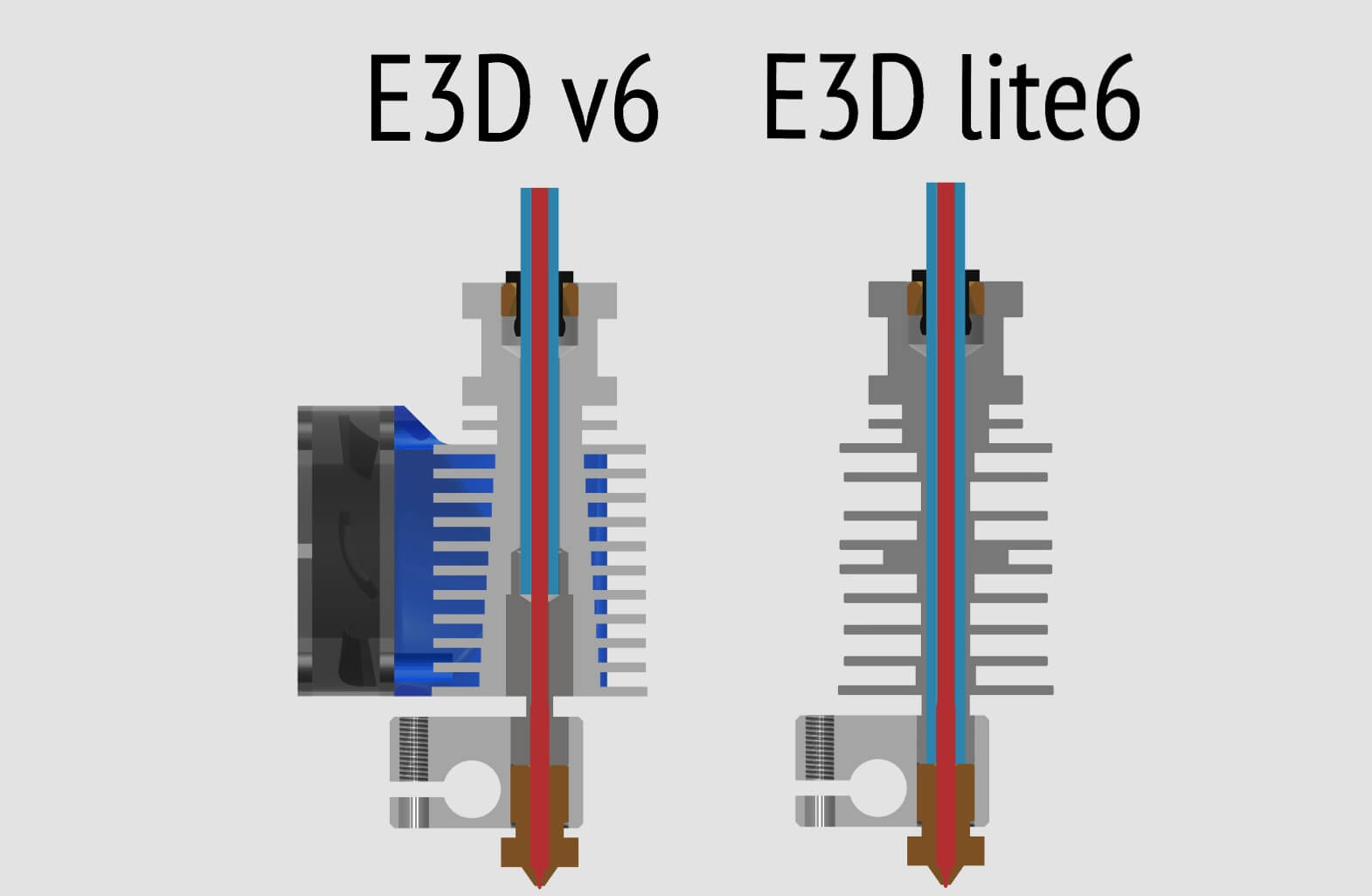

a picture sometimes explains things better than words, so here how a proper E3Dv6 should look like (not the lite version !):

picture is from https://3dprinting.stackexchange.com/ .

dem inscheniör is' nix zu schwör...

Re: Weird print fails

Thanks again!

Yes, that picture matches what I have on my mk2. I just measured the PTFE tube and it's 4mm while the narrowest part of the heat break is just 3mm on the outside so it's clearly impossible for the PTFE tube to go all the way down into the melt zone, the way the video says it should. That video should maybe be updated? (Hint, hint, Jo and Dave!)

Anyway, I think I'm strightened out now. Once the new thermistor arrives, that is...

/Torsten

Re: Weird print fails

Yeah, that's what I suspected as well.

Thanks for the very helpful info!

/Torsten