TPU on the Mk2

So, yesterday I received a shipment of 7Kg of PLA for my next print from my local filament supplier... (I also buy filament from Prusa Research, but use the local manufacturer for basic colours because I can get next day shipment and I only pay €18 per kilo and €5 for delivery.)

Anyway, he sent me a couple of sample filaments that I have not tried - TPU and PETG. He recommended the TPU print temps as 240/30.

I was interested to try the TPU and as the Mk2 had just finished a print, I downloaded that ubiquitous octopus and sliced it, uploaded the GCode to OctoPrint and set the print off.

The settings I used:

Extruder: 245 first layer then 240

Bed: 60

Extrusion width: 0.4mm

Filament tension screws: really loose

Perimeter: 10mm/s

Loops: 20mm/s

Solid: 20mm/s

Sparse: 30mm/s

Retraction 0.5mm @ 40mm/s (suck and prime)

Part Fan: 100% after the first layer

Unfortunately, I also left Z Lift (0.4mm) turned on by mistake and I think this contributed to stringing...

After a couple of hours the print finished and I left the printer to cool for a further hour while I went to the airport to collect a friend.

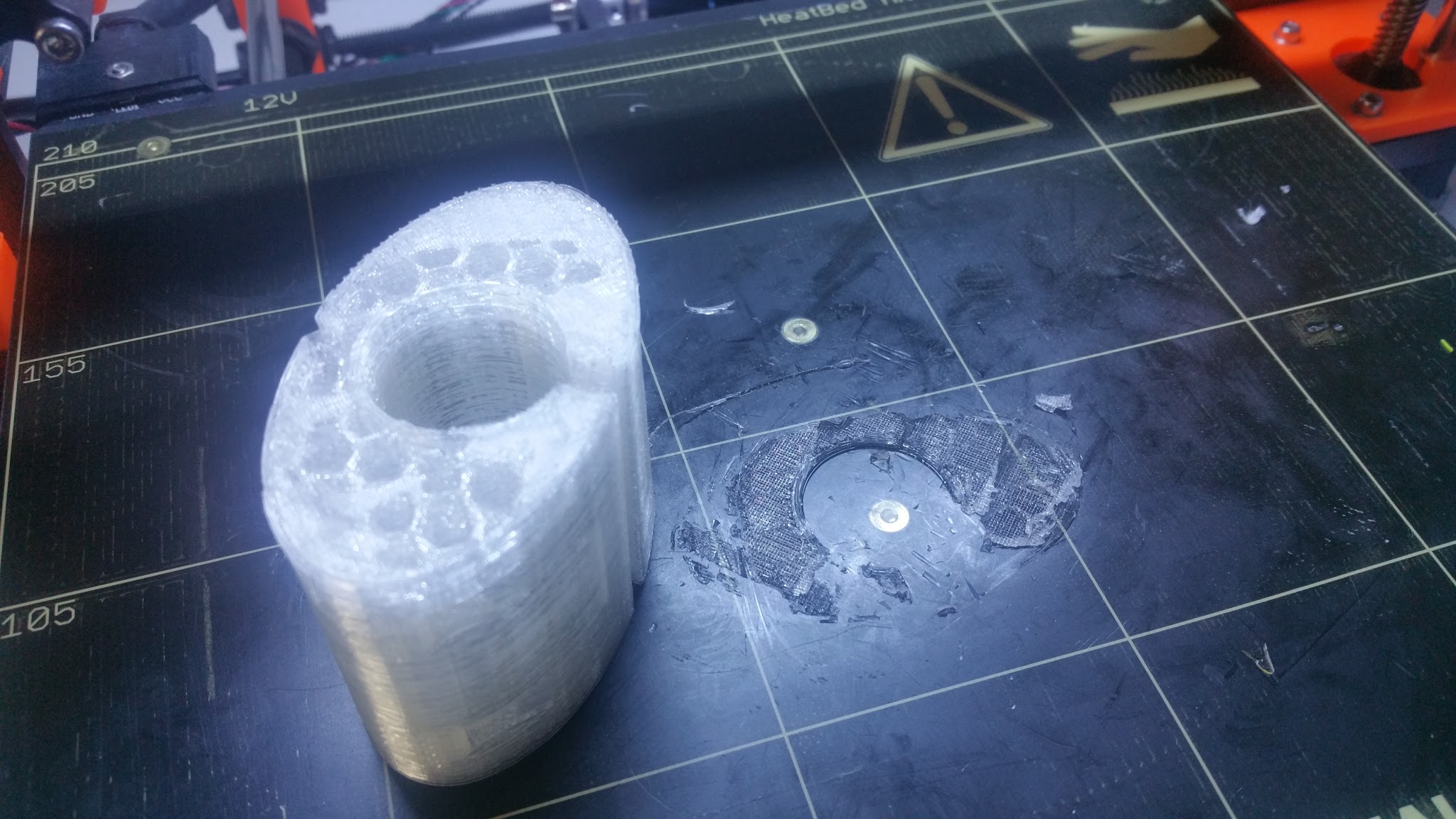

I then attempted to remove the print from the bed, but the PEI was simply not letting go! I ended up using an exceedingly sharp blade in combination with a 1" wood chisel; I only slightly scratched the PEI sheet in one place.

But the result was quite remarkable; my kids did not believe that I had printed such a flexible object. I was very impressed for a first print with this material and I made a mistake or two so it could have been better.

Have to say that I probably won't use TPU again as I can't really see a need to print with it and the problems with releasing it from the bed, but I enjoyed the experiment. I will test out the PETG later in the week when I find a decent small model to try it with.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: TPU on the Mk2

I've just received some ninjaflex myself that i was going to try today, what do you attribute the increased adhesion to? Wondering if you'd suggest tweaking either bed temp or z height based on your recent print. Ill let you know how it goes once i print (also the ubiquitous octopus).

Re: TPU on the Mk2

Kevin

First thing was that I used a heated bed and significantly hotter than advised, but I didn't have a clue how the PEI would work with TPU, so I took no chances as it were.

TPU really does stick well to itself, so I guess to would do the same with most types of bed. I think next time I will put down a layer of blue tape just in the area I am printing.

With regard to first layer height, that is set to 0.18mm with a 60 degree bed and a first layer extrusion height of 0.2mm, so there is very little over adhesion/squish on the first layer.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: TPU on the Mk2

So i just printed an octopus with the ninjaflex with a 40 degree bed temp and still had a ton of adhesion and took a while to get it peeled off. I start with an extruder temp of 230, per the Prusa Slicer settings for flex, but eventually bumped it up near 240 as it seemed to work better. I had my infill speed way too high and had barely anything printing, but it actually worked out pretty well and now my octopus is squishy! 😀

I had my retraction at 2mm and still had lots of stringing, i think a coast setting would be good for this material to help relieve some of the extruder pressure before a travel move (when the globs and whiskers appear).

Re: TPU on the Mk2

Not all flexible filament are the same, so YMMV depending on what brand you are using.

I've been using Ninjaflex, it stick very well even on a cold PEI bed. You pretty much have to pry it off. Started off with some heat but realized quickly that that was not necessary. I print at 230C, no heated bed, cooling fan enabled, w/ a speed of 35mm/s.

Re: TPU on the Mk2

I haven't printed with Ninjaflex since upgrading to an MK2. I have read in other forums and the Lulzbot forums that for materials like Ninjaflex you should use a glue stick. Apparently once cooled it makes pulling the printed object off much easier off of a PEI print bed.

Re: TPU on the Mk2

I found an easy way to get just the right amount of adhesion to the bed for flex/TPU filament.

I just put a tiny bit of talcum powder down and rub it around.

I wipe of any extra with a dry paper towel so there's just a shadow of powder left.

Then it still sticks great, but also comes off easily.

I made a video showing what I mean:

I think I am using less and less powder all the time…less than in the above video whch I made a couple months ago.

When I switch to PLA I just clean the bed with 91% alcohol and have no problems. Sometimes I cleaned twice just out of paranoia.

I'm using an original Prusa i3 MK2 printer with Flexible TPU 3D Printer Filament from Foxsmart.

http://thefoxsmart.com/product/flexible-tpu-3d-printer-filament/

I also did a bunch of tests and found 210-220°C hot end and 50-60°C bed temps at 30mm/sec speed worked great. I haven't used it for a month or so, but I think the retraction was 1 or 2 mm.

Re: TPU on the Mk2

Hi Maxim

Yeah, I saw your video about 6 weeks ago and since then I have been making that suggestion.

Thanks for your help with this!

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: TPU on the Mk2

I found an easy way to get just the right amount of adhesion to the bed for flex/TPU filament.

I just put a tiny bit of talcum powder down and rub it around.

I wipe of any extra with a dry paper towel so there's just a shadow of powder left.

Then it still sticks great, but also comes off easily.

I made a video showing what I mean:

I think I am using less and less powder all the time…less than in the above video whch I made a couple months ago.

When I switch to PLA I just clean the bed with 91% alcohol and have no problems. Sometimes I cleaned twice just out of paranoia.

I'm using an original Prusa i3 MK2 printer with Flexible TPU 3D Printer Filament from Foxsmart.

http://thefoxsmart.com/product/flexible-tpu-3d-printer-filament/

I also did a bunch of tests and found 210-220°C hot end and 50-60°C bed temps at 30mm/sec speed worked great. I haven't used it for a month or so, but I think the retraction was 1 or 2 mm.

Nice! I will test that!

I just printed some Flexible TPU, it seems to cause less feeding issues than the FilaFlex roll i have, but the adheasion is like.. damn!

Me on MyMiniFactory!

Me on Instagram

3D Printing Live Feeds

Prusa MK2 Usergroup Slack Live Chat

Unofficial live chat by users for users.

Re: TPU on the Mk2

Or...you could just do what Prusa says and put down glue stick as a separating medium. Works great. I print w/ tpu all the time

Re: TPU on the Mk2

TPU is a nightmare 🙁

A lot of strignging and oozing ! No nice print and not very happy to remove this spiderwebs.

Try Flexible PLA (rigid.ink). This prints fine. But be carefull to use an gluestick, otherwise you will damage your PEI-sheet !!!

Re: TPU on the Mk2

After trying a bunch of different settings I have gotten TPU to print pretty well. I do use a glue stick but none of my tpu prints have a large base so they've been easy to remove. I bought a tool from amazon.com that makes getting under corners easy.

I am using sainsmart TPU. These are just my experimental settings. Your results may vary. My local ambient temp at the end of winter is about 66-68 deg F in my office.

I started with the FLEX settings and modified from there. This is important as it might have different defaults for some sections I did not list.

Printer Settings/Extruder:

retraction to 3mm

Retract on layer change yes

wipe while retracting yes

Filament Settings/Filament:

Extrusion Multiplier: 1 (this helped reduce strings greatly).

Temp: 210 first/ 205 after

Filament/Cooling:

fan always on yes

auto cooling yes

rest default

Print Settings:

Avoid crossing perimiters YES (not sure if needed but makes sense to lessen oozing)

I enable supports for anything that needs it (less than 35/40 degrees slope). Support on build plate only if possible - depends on model.

I use random seam position because tpu being semi transparent you can sometimes see the obvious seam.

Infill your choice but my prints 15% is fine.

this is the tool, cheaply made, doesn't seem super durable but thin and hasn't broken so far.

https://www.amazon.com/gp/product/B01BUZUXXC/ref=oh_aui_detailpage_o01_s00?ie=UTF8&psc=1

The retraction and extrusion multiplier changes were the biggest factors in reducing strings for me.

Hope it helps.

Re: TPU on the Mk2

The retraction and extrusion multiplier changes were the biggest factors in reducing strings for me.

Problem is that if you are not using a modified PTFE tube, a 3mm retraction can cause blockages.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: TPU on the Mk2

I'm using Hatchbox TPU

Also, watch Maker's Muse YouTube TPU video.

I have S3D and followed his recommended settings.

The prints were great, but I couldn't hardly remove from bed.

Now I'm doing a test with the glue stick.

I just heard of this trick, it doesn't seem like glue would be the answer.

edit here.. I just removed the test print. No problem !!

The glue is the answer to keep the bed from getting chewed up with the knife.

And here's a link to the Maker's Muse video about the S3D settings for MK2

Re: TPU on the Mk2

The retraction and extrusion multiplier changes were the biggest factors in reducing strings for me.

Problem is that if you are not using a modified PTFE tube, a 3mm retraction can cause blockages.

Peter

I tried 2mm and less as well, but that was before the multiplier settings. I'm betting I can go back to 2mm (or even 1.X) with the multiplier lowered as it was. So far the 2 dozen or so TPU prints have gone smoothly.

Re: TPU on the Mk2

I can offer a few tips here as I do 99% of my printing in TPU (for racing drone covers) and I use supports too 🙂

Firstly raise your z height on first layer - do not smash it in to the bed. You want to almost lay it on the bed as it'll stick pretty well by itself. As a guide i back off 0.100 ish from my PLA setting. I also find I don't need to loosen off the extruder bearing either and I do a lot of filament switching.

Also make sure you wipe some forehead grease on the bed this will also make it a lot easier to get off later. Do not wait for it to cool after printing, just pry it off else it likes to stick real hard.

For print settings I use the following for S3d:

Extrusion Multiplier 1.1

Retratction 2.75 mm

Retraction speed 60 mm/s

Layer 0.2mm

First height 100

First width 100

First Layer speed 70%

Print temps:

Extruder 210deg

Bed 55deg

Cooling 100%

Speeds:

Default print 20mm/s

Outline 100%

Infill 100%

Support 100%

Advanced (ooze) unchecked everything except:

Check minimum travel for retraction 1.0mm

Check Only wipe extruder for outer most perimeters

These work for just about every print but they aren't fast.

Re: TPU on the Mk2

I also use talcum powder.

I start of with an clean bed, take a _very_ small amount of powder on a kitchen paper and apply it to the bed, it's so small amount that I barely can see anything on the bed itself.

In my opinion it works better than glue sticks an is easier to clean after print.

Re: TPU on the Mk2

Glue stick here. No problems there, just getting a print to complete without winding up with a spool of filament on my desk. That seems to be my issue.

Re: TPU on the Mk2

I printed TPU successfully (albeit slow...) with my Original i3 mk2 going with your tips here, mostly slow and nearly no idler pressure on PVA Stick glue.

I printed PLA after with no problem (in middle of the bed, TPU I printed on a corner). Then I wiped the PVA away with water and then alcohol. Now PLA does not stick very well on the PEI (all over the bed). Acetone did not help, all the PEI looks more glossy now. Seems some of the PVA sits in the pores?

PETG seems to stick better.

Any hints how to clean further? I maybe also try to print PETG all over the bed maybe this restores my bed adhesion.

Carsten

My Prints: https://www.prusaprinters.org/social/15695-carsten/prints

My Employer: https://make-magazin.de