Printing using bioFila

I started printing with bioFila from Twobears in Germany today, but it's been a disaster so far. 😀

The strength of the printed parts is very poor, I can tear the layers apart by hand. I printed at 195C nozzle and 55C bed temp.

Removing the printed part from the PEI sheet is almost impossible without damaging PEI sheet and / or the part.

The Twobears website recommends printing at 195C for optimum strength, but either my printers thermistor is off, or something else is amiss.

I'm really keen to learn how to use this material, it sounds very promising, but obviously there is a lot to learn.

So please share if you had some success with bioFila on the Pruse MK2, to make this thread a collection of useful tips and tricks for bioFila printing.

Re: Printing using bioFila

Some questions:

How come other filaments produce stronger prints at higher temperatures, but bioFila is supposed to be strongest at the bottom of the temperature range in the diagram shown above?

Is bioFila hygroscopic (does it attract water)? The filament arrived in a cardboard box without plastic bag or desiccant. Could my woes be due to moisture laden filament?

Could it be that my temp sensor is off? I think it is not particularly likely, because bioFila seems to be running out of the nozzle quite freely while pre-heated to supposed 195C.

Re: Printing using bioFila

i used to print the biofila platec stuff @ 215°C (first layer 220°C), so layer bonding is very strong.

until now i didn't notice any hygroscopic behaviour of that filament.

by the way: haven't noticed that they've other colors than black and natural.

dem inscheniör is' nix zu schwör...

Re: Printing using bioFila

I just had an idea about the excessive adhesion to the print bed: I can start printing with standard PLA, then switch to bioFila after the first layer or so.

I bought some yellow ('Sun'), green, natural and black. Blue is out of stock.

Re: Printing using bioFila

I just had an idea about the excessive adhesion to the print bed: I can start printing with standard PLA, then switch to bioFila after the first layer or so.

I bought some yellow ('Sun'), green, natural and black. Blue is out of stock.

yes, i do some similar procedure when i try to print with nylon stuff (which won't stick to the pei sheet): i'll print a base of petg ;-).

dem inscheniör is' nix zu schwör...

Re: Printing using bioFila

I'll try to take a systematic approach and test the bioFila with some simple tests that I made up while experimenting with other filaments.

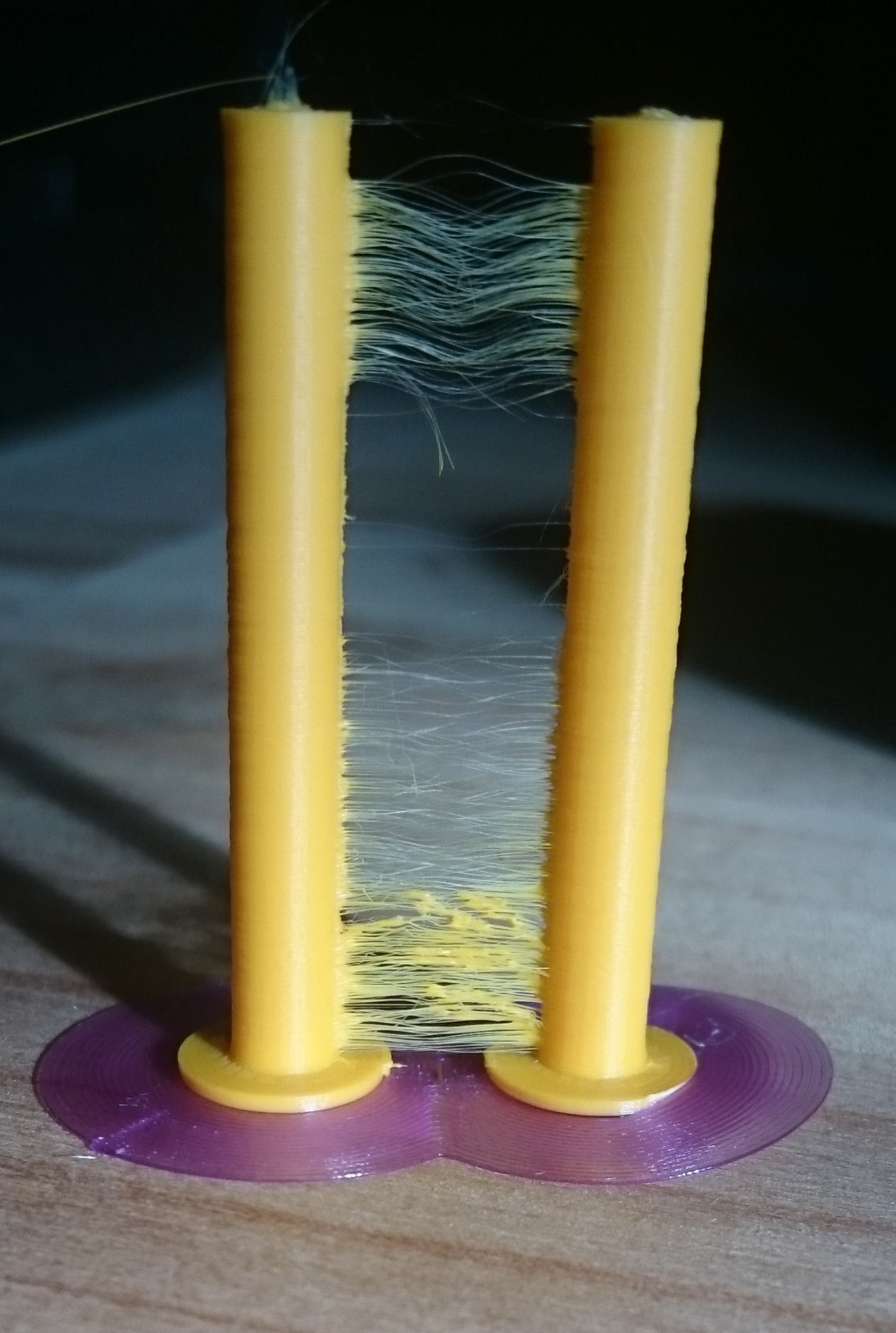

First, the 'Two Towers': Using little filament to test multiple temperatures for strength (mainly inter-layer adhesion) and stringing, and surface texture.

I started the print using X3D transparent purple PLA and manually changed to bioFila Sun at z 3.0 / z3.1.

Start temperature 230C nozzle, reducing by 5C every 5mm to 195C. Bed temp 65C all layers.

OpenScad

$fn=150;

cylinder (h=41, r=2.5);

cylinder (h=1, r=5);

translate([15,0,0]){

cylinder (h=41, r=2.5);

cylinder (h=1, r=5);}

Slic3r settings: SLIC3R_Settings

0.10mm_BioFila-Fins_2017-05-22

Starting out from PRUSA 0.1mm setting

External perimeters increased from 3 to 4.

Unticked: Ensure vertical shell thickness

External perimeters first, random.

Infill 5% cubic

No skirt

Brim 7mm

Speed reduced to 30mm maximum

bioFila_Sun_2017-05-23-calibration-towers

230C start temp nozzle

65C bed all layers

EM 1.087 (100/92 mm extruded)

Start-and-End_X100-Z200_Bed250x205

Then export .gcode file from Slic3r and open it in a text editor.

Search for the right spot in the code by pressing Ctrl + F, type "z11" to find where the z-height gets to 11mm for the first time. Then, insert a nozzle temp command just above (or really anywhere in the vicinity) of that z11 line. Repeat for z16, z21, z25, z31, z36 with nozzle temp lowered by 5C every time. Below is a summary of the added code and the lines just below where the added code was inserted:

Temperature code changes

M104 S225 ; set extruder temp

G1 Z6.000 F7200.000

;

M104 S220 ; set extruder temp

G1 Z11.000 F7200.000

;

M104 S215 ; set extruder temp

G1 Z16.000 F7200.000

;

M104 S210 ; set extruder temp

G1 Z21.000 F7200.000

;

M104 S205; set extruder temp

G1 Z26.000 F7200.000

;

M104 S200 ; set extruder temp

G1 Z31.000 F7200.000

;

M104 S195 ; set extruder temp

G1 Z36.000 F7200.000

I'll let you know the results when the print has finished.

Two Towers results

Print time 0h 59min

Zero stringing at lower nozzle temps, minor stringing at higher temps. None bad enough to cause me any concerns for what I want to print.

Sticks nicely to the PEI sheet, comes off nicely too (because the bioFila is not touching the PEI at all).

Snapping-off-with-bare-fingers-test:

195C snaps off easily, and squishes with pliers to a mess of separated layers.

200C breaks off easily, but squishes with pliers to a flattened cylinder without layer separation.

After that, it gets hard to snap it off by hand. The next snap occurred at z 16.72, just above the transition to 215C nozzle temp. The fragment is 9.2mm long, so it is comprised of material extruded at 215C and 210C. After squishing it multiple times from different angles using pliers, the layers still separate here and there.

The remaining bit broke off at the junction with the base layer from X3DtpPLA. EXACTLY at the junction, which means it does not bond too well and it may turn out to be a problem using the base layer PLA method to facilitate removal from the PEI sheet. Large prints at risk of warping may well separate at the line between PLA and bioFila PLA.

The higher temperature end of the tower is clearly stronger than the lower temperature end, like with other filaments.

I suggest someone does a test print with a temp range of 215C to 245C or thereabouts. I'll do it later when I get a chance but it could take a while.

The second tower is still intact for refined testing, in case anyone has suggestions how to test this better.

For now, I think the diagram and explanation that highest strength is achieved by printing at 195C is wrong. I believe (without testing) that it is also likely wrong that lower layer height causes higher strength, because that is (AFAIK) also diametrically opposed to the usual behaviour of extruded plastic filament objects.

Re: Printing using bioFila

How did you post process the print? Did you anneal the object using hot water?

Re: Printing using bioFila

How did you post process the print? Did you anneal the object using hot water?

No, I did not use any post processing. Good thought though. But will boiling water be hot enough for annealing this stuff?

Re: Printing using bioFila

I'm not sure if the video is showing how to anneal or just showing the heat deflection.

Re: Printing using bioFila

Also, did you following the recommended print speeds?

Re: Printing using bioFila

Also, did you following the recommended print speeds?

Certainly. Maybe I made a mistake, but my intention was to recreate the bioFila recommended setting for maximum strength. And I don't think I made a mistake, but I may be wrong (liberally quoting Cohen, HAHA!).

Re: Printing using bioFila

Now printing 2Towers_bioFila_230-65-80C_0p1mm_edit_230-215-235-212C.gcode

It prints the bottom 20mm at 230C, then 10mm at 215C, then 8mm at 235C, then 2mm at 212C.

Start with X3dtpPLA, manually change to bioFila Sun at start of second layer. The (untested) idea is to increase bed temp to 80C to improve bonding between layer 1 (PLA) and layer 2 (bioFila Sun). The bed heats up while filament is being changed manually.

Manual .gcode edit: 230-215-235-212C

M104 S230 ; set extruder temp

G1 Z6.000 F7200.000

;

M104 S215 ; set extruder temp

G1 Z21.000 F7200.000

;

M104 S235 ; set extruder temp

G1 Z31.000 F7200.000

;

M104 S212; set extruder temp

G1 Z39.000 F7200.000

The idea behind the change to 212C at the end is to prevent potentially over-cooked filament from blocking the extruder.

SLIC3R_Settings

0.10mm_BioFila-Fins_2017-05-22

Starting out from PRUSA 0.1mm setting

Setting made for optimal strength

External perimeters increased from 3 to 4.

Unticked: Ensure vertical shell thickness

External perimeters first, random.

Infill 5% cubic

No skirt

Brim 7mm

Speed reduced to 30mm maximum

bioFila_Sun_230-65-80C_2017-05-25

for use with base layer of PLA

230C nozzle all layers (before manual editing as above)

65C bed first layer, 80C all other layers

EM 1.087 ( 100/92 mm extruded).

Start-and-End_X100-Z200_Bed250x205

Re: Printing using bioFila

The difference in mechanical strength between 230C, 215C and 235 C is not extremely large, but I get the impression that 215C is weaker than 230C and 235C is stronger than 230C.

Stringing is markedly worse at higher temperatures.

I wonder why the stringing looks worse at 230C than at 235C?

Vertical surface is rougher at 215C, smoother at 230C, and even smoother at 235C.

Re: Printing using bioFila

I am getting some success with the bioFila printing now.

The technique of printing 'standard' PLA as first layer works very well. I have not done systematic trials of various temperature settings etc., and what I use may or may not be optimal. But, it works for me for now.

Bed temp 65C and nozzle temp 230C for first layer.

Bed temp 80C and nozzle temp 230C for the rest of the print worked well, but now I'm trying 220C nozzle temp, just 'cause I recently read the label on the bioFila box and noticed that 220C is the recommended maximum temperature.

I don't know how on earth how they measure strength, and how they conclude that bioFila prints' strength is increased at lower nozzle temperature and with 0.1mm layer height. For now, I bet they are wrong and this filament produces higher strength prints at higher temperatures and with thicker layers, just like the rest of them. I'd all too happy to be shown that I'm wrong, that would be most interesting.

So, I'm moving on to using 0.15mm layer height and standard Prusa print speeds, at 220C nozzle, for now.

The bed temp of 80C from 2nd layer is chosen to maximise adhesion between PLA (using X3d transparent purple PLA) and the bioFila Sun 2nd layer. And, it raises the temperature in the enclosure to around 30-32C, which can only be good for preventing warping problems.

Re: Printing using bioFila

After multiple further print attempts I have come to the conclusion that bioFila (at least the SUN variety) is rubbish for anything requiring structural strength.

Maybe it has good compression strength, but the inter-layer adhesion is poor compared to PLA.

I can easily tear apart any fin I print with bioFila Sun, by hand.

I can also fairly easily break apart a Benchy by hand. Not so with X3D transparent PLA.

I can confirm that it does not warp much, very similar to PLA, not sure if exactly the same.

In short, it is not as good, but is more expensive than standard PLA.

Re: Printing using bioFila

@MrMik:

thank you for your tests.

seems that there is different stuff under the "biofila" label on the market (maybe even fakes or counterfeits) and that we have to be careful with what we get.

dem inscheniör is' nix zu schwör...

Re: Printing using bioFila

I'm certain I ordered it right from the source, had several email conversations with them.

I don't think I have 'counterfeit' filament, but maybe a bad batch could be possible.

However, the strange claims about better strength at lower temperatures and with small layer heights is baffling all by itself. And, I cannot find any other print reports / reviews.

Did you get good results, and if so, which color of the bioFila filament did you use? I have Sun, Fresh, Jet and PlaTech, but I have only printed Sun so far.

Re: Printing using bioFila

The diabolical adhesion to the PEI sheet would be hard to fake, I guess!

Re: Printing using bioFila

I just picked up some of their PowR filament which seems to be an improved PlaTec like formulation. Unfortunately I'm seeing the same issues with layer adhesion. It's among the weakest of the many materials I have. Which is strange since their page specifically says strong layer bond. I've tried various combinations of temp/speed/fan/etc and it's just a bit too weak for the "strong" parts it seems to have been intended for. Hopefully there's something I'm doing wrong, but unfortunately it's not looking promising so far. Fan, as expected, unfortunately reduces layer bond but is necessary. It certainly is the nicest filament I have though in terms of aesthetics. Has anyone solved this or had better experiences?