Re: Polycarbonate: Here's how to print it without warping, delamination, or an enclosure, with better-than-ABS results.

After unsuccessfully trying to print this design:

https://shop.prusa3d.com/forum/hardware-firmware-and-software-help-f64/playing-with-the-air-nozzle-design-t25642.html#p114404

with my modified Metacollins settings I reverted to the standard Prusa PC settings and adapted them a little for the (assumably) relatively pure HK Polycarbonate. I set temperatures higher and adjusted speed and cooling seetings according to my guesses.

Print turned out almost perfect. Cooling and slowign down layers <20s could be optimized further, but generally it worked very well.

The main issue with Metacollins wide extrusions is the way that Slic3r is slicing with them, leaving gaps between perimeters, holes in infill and slicing bridges with corners. No surprise that the MK3 can't print them.

Lesson learned, I may revert to trying Metacollins approach with bigger and less detailed parts.

Attached the Config.ini and GCode used for the fan shroud.

Re: Polycarbonate: Here's how to print it without warping, delamination, or an enclosure, with better-than-ABS results.

Crap, apparently there is a time limit on editing posts... I would have liked to add this to the top but it's too late =/.

Latest version can always be found at this link:

https://gist.github.com/metacollin/18ecb0a58fb475cfae86e0781bf51325

Change log:

Dec. 07 2017

- Now using 0.9mm extrusion width for nearly a 5:1 aspect ratio

- Bridge flow and overlap changed to compensate

- Bed adhesion notes added

Please forgive my new-bee ignorance but I am trying your latest ini file with a i3 MK3 using esun PC.

Trying to print a test cube, it gets about 3-5mm high and for 3 tries, I get a consistent preheat error for the bed or head.

Trying lame approximation settings for PC using 255 for the head and 85 for the bed, it does not get the error, and it finishes but the print quality sucks.

I did try adjusting your settings for lower bed and head temps, it did print 1/2 the cube, but it was a failure with the cube bowing at the bottom and letting loose.

When using your settings, I do see the head temp drop 5 degrees below the setpoint, I assume from the fan turning on.

I have not installed the modified head fan shroud yet.

Other prints using other materials and default configurations work fine.

I wonder if it is a difference in the MK3 vs MK2 or something else.

Thanks

Wayne

Re: Polycarbonate: Here's how to print it without warping, delamination, or an enclosure, with better-than-ABS results.

I posted some config.ini files above where I transferred Metacollins settings to the Mk3 printer, you can use those as a starting point.

I reach up to 295C on the nozzle and 115C on the bed with the MK3. But the 295 are definitely the limit for the thermistor in the hot end, I would stay away from that. Even the HK PC prints well at 285.

Re: Polycarbonate: Here's how to print it without warping, delamination, or an enclosure, with better-than-ABS results.

Thanks, I will give that a try

Re: Polycarbonate: Here's how to print it without warping, delamination, or an enclosure, with better-than-ABS results.

I posted some config.ini files above where I transferred Metacollins settings to the Mk3 printer, you can use those as a starting point.

I reach up to 295C on the nozzle and 115C on the bed with the MK3. But the 295 are definitely the limit for the thermistor in the hot end, I would stay away from that. Even the HK PC prints well at 285.

That worked very well, thanks for the info.

BTW, when I went to try it, I forgot to change my filament from PETG to PC.

PETG printed fairly well with those settings, but wow, PETG sticks hard to the plate at those temps!

It took forever to get the scraps off the plate.

Re: Polycarbonate: Here's how to print it without warping, delamination, or an enclosure, with better-than-ABS results.

😯 I don´t realy understand how your profile can work, but the results are stunning 😮

Thanks a lot!!! Seriously! Thank you!

Re: Polycarbonate: Here's how to print it without warping, delamination, or an enclosure, with better-than-ABS results.

😯 I don´t realy understand how your profile can work, but the results are stunning 😮

Thanks a lot!!! Seriously! Thank you!

Good to hear it worked for you too!

Yes, when the print succeeds, the HK Polycarbonate gives some really nice, strong and temperature resistant parts!

I'll try printing the NASA wrench tonight, see if something bigger also works.

PS: this is referring to the discussion here:

https://shop.prusa3d.com/forum/hardware-firmware-and-software-help-f64/playing-with-the-air-nozzle-design-t25642-s20.html#p117689

about printing a fan shroud in Hobbyking polycarbonate to solve the issue that ABS printed fan shrouds droop over time when printing at higher temperatures.

Re: Polycarbonate: Here's how to print it without warping, delamination, or an enclosure, with better-than-ABS results.

Managed to print a complete NASA Wrench from Hobbyking Polycarbonate.

Used the settings that had worked for the fan shroud and increased the extrusion width for supports and internal perimeters for strength.

Checked the slicing for gaps.

Crucial for the success was a build plate with fake BuildTak, which sticks very well.

However, the warping forces and high temperature led to (permanent) deformation of the build surface and even some deformation of the spring steel sheet during printing, so the underside of the wrench is curved upwards by about 2mm on the handle side.

Lesson learned:

I don't see a way to print larger HK PC parts without warping, at the temperatures possible with the MK3 and passive enclosure.

The chinese flex plate and fake buildtak surface are an interesting option, I'll next try Nylon with them, that should be easier with regards to temperatures.

Attached the settings and GCode.

Re: Polycarbonate: Here's how to print it without warping, delamination, or an enclosure, with better-than-ABS results.

Here's a video of a complete print with Polymaker PC-Max. I modified metacolins settings quite a bit:

It seems PC-MAX prints fine with the default prusa settings, but metacolins settings are a bit less prone to warping and print much faster. (because the higher extrusion width) Also i use a build enclosure.

Notable changes: I use an extrusion multiplier of 1 and the most important setting was to enable Detect Thin Walls. Otherwise that print has some horrible uglyness at some places. Without this setting it will use the zigzag pattern to fill spaces that are smaller than the extrusion width. However this gives horrible results.

Thanks again metacolin.

Also: I created a script that automaticly livestreams all my prints from now on.

Edwin

Re: Polycarbonate: Here's how to print it without warping, delamination, or an enclosure, with better-than-ABS results.

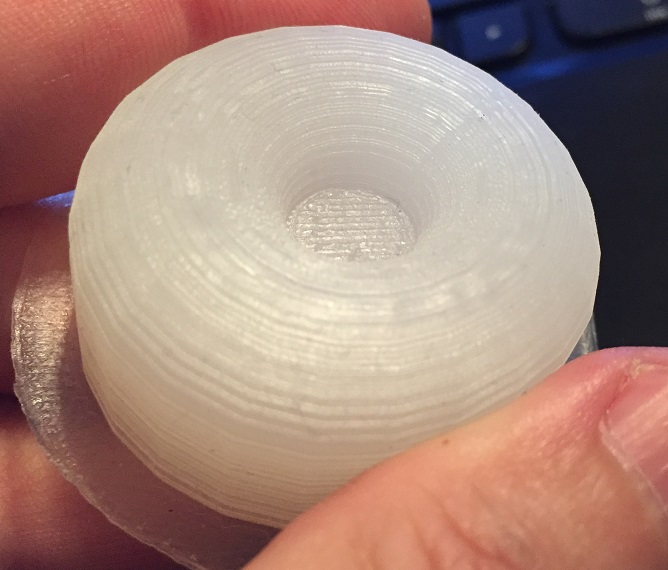

Cross-posting from the RHDreambox fan nozzle topic, I got a good result with HK PC by using the stock Polymaker PC template modified with the following: 270/275 nozzle, 100/115 bed, auto cooling on, fan speed 0-30, bridges 30%, enable fan if < 20s, slow down if < 40s *and* 3 perimeters.

Sample output of the aforementioned nozzle in HobbyKing PC:

Re: Polycarbonate: Here's how to print it without warping, delamination, or an enclosure, with better-than-ABS results.

My attempt with eSun ePC black. I took the Polymaker profile then modified it a bit with all fingers crossed 😯

A bit of stringing and some weirdness with the bow, which I am putting down to my modification of Overlap. No other heavy duty mods required. Very happy with the results. Printing perhaps slightly cooler than would be expected 250/255, with mods to the fan settings (fan is needed for small bits I think).

Re: Polycarbonate: Here's how to print it without warping, delamination, or an enclosure, with better-than-ABS results.

My attempt with eSun ePC black. I took the Polymaker profile then modified it a bit with all fingers crossed 😯

A bit of stringing and some weirdness with the bow, which I am putting down to my modification of Overlap. No other heavy duty mods required. Very happy with the results. Printing perhaps slightly cooler than would be expected 250/255, with mods to the fan settings (fan is needed for small bits I think).

Oh my Lanta. Could you post your exact settings, bed material, and ambient printer temps if you can?

Amazing quality PC Print.

Re: Polycarbonate: Here's how to print it without warping, delamination, or an enclosure, with better-than-ABS results.

Take a look here where I describe using ePC to print the new extruder. Profile also included.

Since then I have tweaked the profile a bit, adjusted retraction settings to cut down stringing (almost gone now). Also slowed down Top Solid Infill to get a better surface finish.

Re: Polycarbonate: Here's how to print it without warping, delamination, or an enclosure, with better-than-ABS results.

do you have Slic3r-pr config files for your evolved Polycarbonate printing?

eSun P Black

TL;DR ESun ePC printed very well with @metacollins settings but needed to be dried first. I will dry it before each print to make sure.

@metacollin,

Thanks for the excellent work on this print profile. I used it with eSun ePC and it worked beautifully. I used a 0.6 E3D brass nozzle with a stock Prusa Mk3, a thin layer of glue stick on the bed. 0.48mm layer height and stuck with the 0.6mm layer width even though I had a bigger nozzle. 240 nozzle temp and 90 bed.

My printing was not without problems, but it was nothing to do with the profile. My first print (on the left of the photo) had a very rough surface, and was weak with poor layer adhesion. I noticed popping sounds and realised that even though the ePC was fresh out of the sealed bag it was full of water. Apparently ePC loves H2O!

After drying overnight (in a cheap food dehydrator from eBay) I produced the second print in the pictures (on the right) - outstanding quality and strength. This model is a decorative knurled box with a very thin section between the knurled portion and the thread. After the first test print I decided to try it at full size. Typically the thread area is very weak and collapses under a bit of hand pressure with PETG and PLA. I couldn't crack it using my full strength in the ePC version - very impressive.

RE: Polycarbonate: Here's how to print it without warping, delamination, or an enclosure, with better-than-ABS results.

Thanks for the excellent work on this print profile. I used it with eSun ePC and it worked beautifully. I used a 0.6 E3D brass nozzle with a stock Prusa Mk3, a thin layer of glue stick on the bed. 0.48mm layer height and stuck with the 0.6mm layer width even though I had a bigger nozzle. 240 nozzle temp and 90 bed.

EDIT: Temperatures were 260 nozzle and 110 bed.

RE: Polycarbonate: Here's how to print it without warping, delamination, or an enclosure, with better-than-ABS results.

I posted some config.ini files above where I transferred Metacollins settings to the Mk3 printer, you can use those as a starting point.

I reach up to 295C on the nozzle and 115C on the bed with the MK3. But the 295 are definitely the limit for the thermistor in the hot end, I would stay away from that. Even the HK PC prints well at 285.

@georg-s2 I think some forum reconfigurations have eaten your attachments. Can you repost? Thanks!

RE: Polycarbonate: Here's how to print it without warping, delamination, or an enclosure, with better-than-ABS results.

I printed with PC for the first time yesterday - much easier than I expected:

MK3s. 0.4mm noz. 0.20 layer height. PrusaSlicer 2.0

"Fillamentum ABS" basic profile, modified to 120 degree bed and 290 degree nozzle. I also added a 0.4mm elephant foot compensation and 50% in fill for the job (electronic project enclosure).

First time, perfect prints.

RE: Polycarbonate: Here's how to print it without warping, delamination, or an enclosure, with better-than-ABS results.

That’s great. I’m heartened by the success Prusa owners are having with PC. I think filament manufacturers are producing much easier printing compositions of PC these days.

Which brand of filament did you use?

RE: Polycarbonate: Here's how to print it without warping, delamination, or an enclosure, with better-than-ABS results.

Downloaded the ZIP file from github, generated the G-code and sent to printer....Printer started calibrating each point and literally plunged straight in to the bed with a lot of force while dragging the nozzle across the bed to each point. What the hell is that about?