Perimeters not sticking together

Hi !

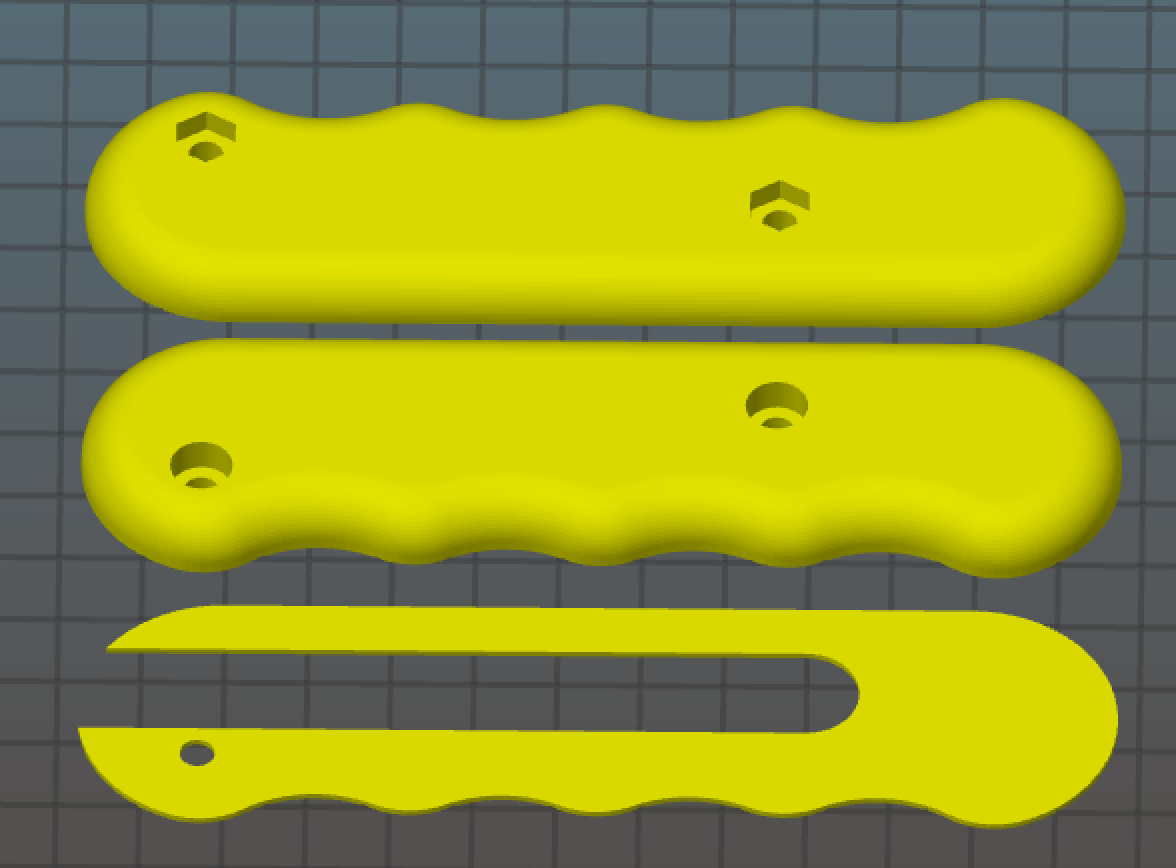

I'm trying to print this simple model of handsaw handle from Thingiverse and have a problem with external perimeters not sticking together on the curvy part of the handle:

My Slic3r settings are: layer height 0.2 mm, perimeters 3, solid top layers 5, solid bottom layers 5, infill 25%, nozzle temp 215, bed temp 55, no brim and supports.

Tried different extrusion widths for perimeters: default value 0.45 and 0.75 mm. Approximately on 4th layer the external perimeter tends to detach from neighboring perimeters..

How to solve this ?

Re: Perimeters not sticking together

Does this part of the handle have an overhang. If yes then there is not enough overlap from the previous layers. Try the 0.15 or 0.1mm layer height which will help as the lower the layer height the more overlap is created on a overhang. Another option is to use a 0.6 nozzle.

Re: Perimeters not sticking together

Looking at the model, the only overhangs are the narrow cutout for the saw blade on the small end of the part.

Difficult to tell from you photo, are these strings on the first layer?

Looking at your photo more closely - did you stop this print before it finished? Did you re-orient this part before you sliced it (flat part on the bottom)?

-Kevin

Re: Perimeters not sticking together

@kevin:

There is an overhang shown below in red

The first 3 layers are good and strings appear from 4th layer and higher

Yes, the print on the photo was aborted (I just tried different settings in slic3r), model wasn't reoriented.

@lee:

Thanks, I will try 015 / 0.1 mm layer height

Re: Perimeters not sticking together

I have downloaded the STL and it is definitely the overhang causing the issue. In Slic3r if you flip the part over and slice it you can see there is not enough overlap. I think you might have to even go down to 0.05mm to get enough overlap while printing in the orientation shown in your post.

If it was me I would print this flipped over so flat face down at 0.2 or 0.15mm and rely on the excellent bridging of the machine. Set the supports z contact distance to 0.07mm and have a solid interface layer on the supports. Select do not support bridges and try that.

Re: Perimeters not sticking together

My mistake - I was thinking you had flipped the part over before slicing & printing.

There is another option if you don't want to deal with supports or bridging. You can flip this part over and then use the "Cut" command from Slic3r (under the "Object" menu) to cut this part at 0.8mm. Then just print it as 3 objects instead of 2.

-Kevin

Re: Perimeters not sticking together

Looking at this again, and splitting the part the way I showed above would probably make the saw blade more likely to slip out the top of the handle. Probably best to print as suggested by lee.g

-Kevin

Re: Perimeters not sticking together

I've managed to print saw handle problem part at 0.1 mm layer height (0.15 has failed also as 0.2).

But for example another model with overhang has failed to print even at 0.1 mm resolution and I had a similar issue with the strings on first layers.

This is a model (STL file):

So I'm still wondering what are the best settings for such overhangs in Slic3r..

Re: Perimeters not sticking together

Tricky part to print. Is this a part you modeled or was it downloaded. If you are modeling then this part can be tweaked to make it more sympathetic to the FDM process.

If you have downloaded then you have a couple of options.

1. print with support but it will likely be slightly messy

2. It looks like a fairly easy model to reverse engineer so you can tweak it to make it easier to print.

3. Maybe change the orientation and cut the part but looking at it quickly you might have to cut into 3 parts because some of the angles would still be to steep without supports.