Layer separation and bad infill, but perfect when hollow?

Had a bizarre issue pop up yesterday and haven't been able to find a fix here or elsewhere. Out of the blue I started getting bad layer separation and bad infill when when trying to print anything. I did a few that were hollow, and they were perfect, but if I try infill, it goes bad rather quickly.

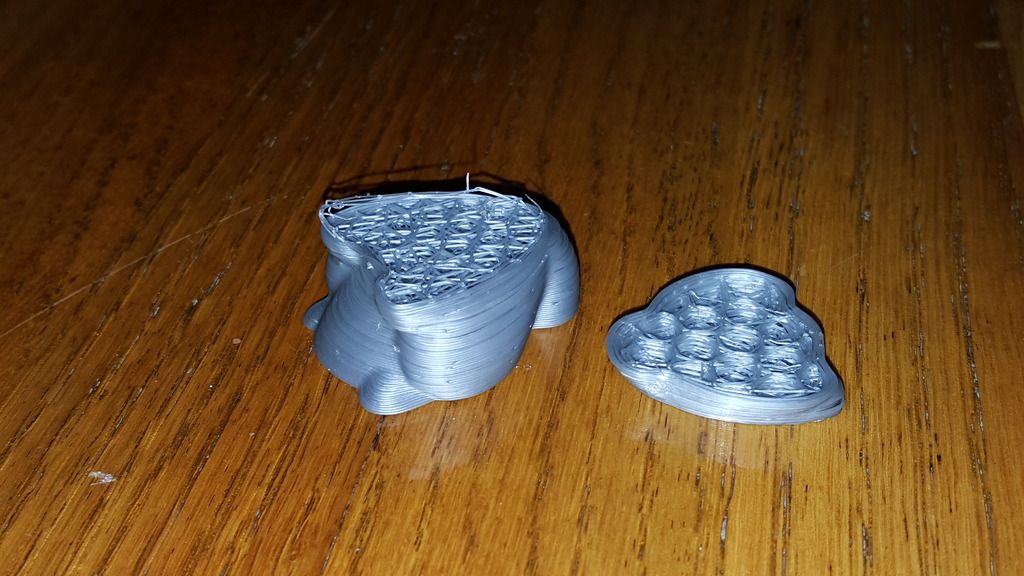

After tuning in my settings with the hollow pacman, and tried to print several will infill using the same settings. Got bad layer separation on all of them, so I thought it could be the model and switched to a squirrel with infill. Same issue, with separation and weak/weird infill.

I switched filament back to the silver which prints flawlessly, and still have the same issue.

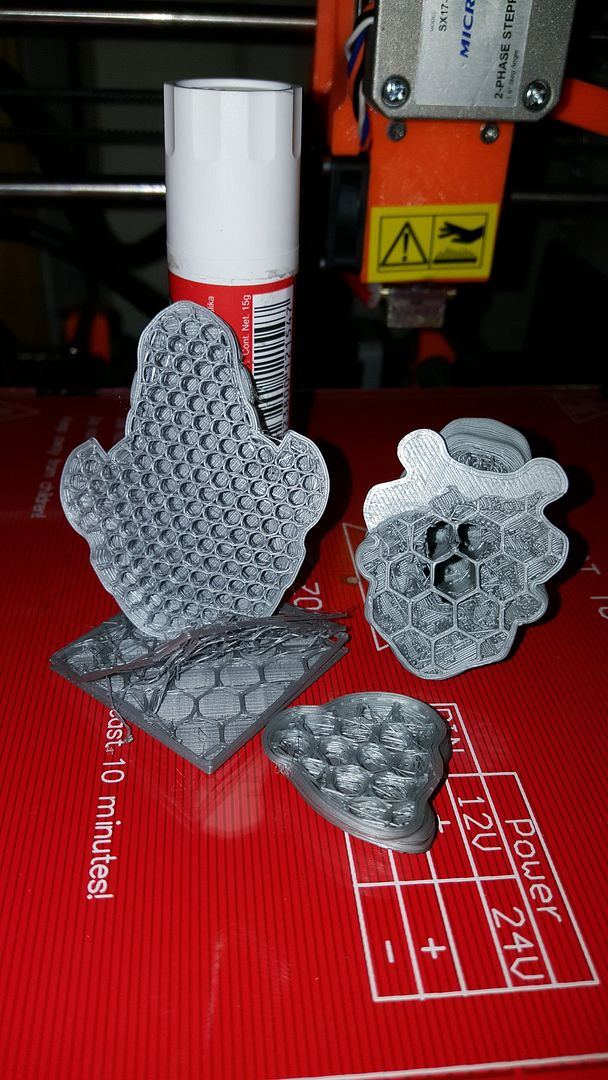

I thought maybe it was an issue with Slic3r, so I reinstalled the one from here with the proper settings, but that didn't do it either. Wanted to make sure it wasn't the model, so I did another squirrel hollow, and it printed very well for a 2mm quick print as you can see below. Same squirrel with infill has issues, but not nearly as bad as the previous ones.

Initially I thought it was a speed issue, as my infill has always been perfect up until yesterday (regardless of the speed) and I had fooled around with slicer settings once I got my printer leveled and pulled off some great prints. The re-installation told me that speed and some of the settings were definitely an issue before the reinstall, but the infill issue is still present if not nearly as bad. People were actually impressed by a finished models with hexagon fill and now it's noodily.

Have done nothing to the machine, using a new hardened nozzle and the material appears to flow freely when I load filament and when it extrudes. Basically the same way it looked since day one and I don't notice anything amiss on hollow prints. Clueless on how to proceed as I have no idea why the infill is bad, when the bottom layers are good... and the shells are good on solid models.

Re: Layer separation and bad infill, but perfect when hollow?

Hi Adam

First thing to do is to try printing one of the supplied gcode files - probably the tree frog. Look at that to see if the same problems are present. If not, you know it's slicer settings.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Layer separation and bad infill, but perfect when hollow?

Is there a good small one to try on there with infill?

I can't remember what was on there exactly and am getting low on the silver. I have other filaments to try, but this is the one I know printed well before the issues.

Re: Layer separation and bad infill, but perfect when hollow?

Marvin, Adalinda, Castle, Tree Frog. All PLA and all with infill (Adalinda/Castle being the larger ones).

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Layer separation and bad infill, but perfect when hollow?

I started Adalinda, and stopped it at 10% as I don't have enough filament left on the spool for a 10 hour print. As you can see from the photos, the fill looks better and the layer separation issue appears to be gone. I'm not sure what the fill percentage was on the model, but it looks to be more than the usual 15-20% I've used on everything else.

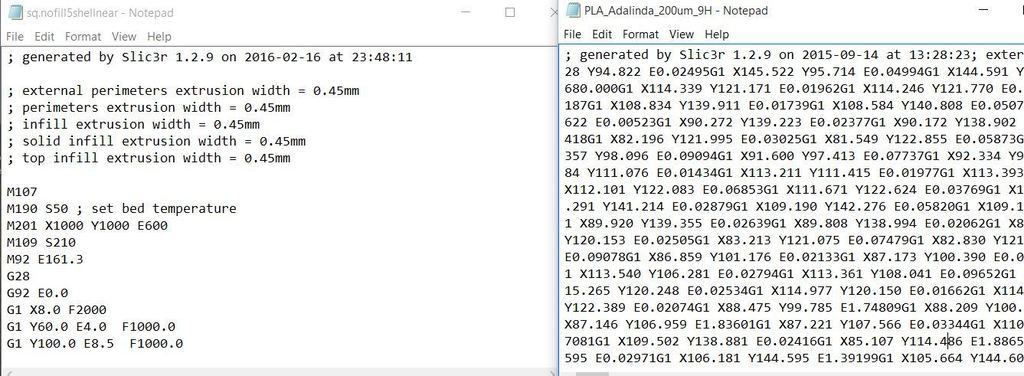

I did notice something odd when I opened up the Gcode to take a peek. As you can see by the screen below, both were generated by Slic3r, but the one I did on the left has a totally different format for some reason. Would this be the issue in some way? The only change I made to the stock settings in Slic3r was to check the box to generate a preview in the background so I could see the layers. Other than that, everything is as it was.

Re: Layer separation and bad infill, but perfect when hollow?

Hi Adam

The fill used on Alalinda was 22%. Extrusion width 0.45mm.

You need to open up the gcode files with something like Notepad++ in order to read it properly. Window Notepad is pretty poor at displaying files which don't have the LF/CR line delimiter pair. Unix-style text documents use a simple LF character which Notepad does not understand.

All the parameters used during the original slicing are stored at the end of the document, so you should be able to extract from that the settings needed to get your printer working properly.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Layer separation and bad infill, but perfect when hollow?

I dug through them all earlier, and they appeared to be an exact match as they should be as it's factory settings. I will go through it again though, as I just tried slicing four different objects and am still getting crumbling pieces with bad fill unless I use no infill at all.

Does the formatting not look off to you from the photo? They were opened the same way, same program, and look entirely different format-wise. It's like slic3r is exporting the gcode in a different format or pattern, even though both are 1.2.9.

Re: Layer separation and bad infill, but perfect when hollow?

Adam

I don't use Slic3r, so I don't know how it generates its gcode files; I would assume that the files provided by PR could have been generated on a different platform (MAC, Linux) hence the difference in output. However, I would presume that there is no difference from the printer's viewpoint (it would simply ignore CR characters).

If it would help, I can slice a model for you using KISS to see if the problem goes away? Zip up an STL and drag it onto here as an attachment, give me 10 minutes and I will upload the gcode.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Layer separation and bad infill, but perfect when hollow?

Okay, I got NP++ and opened them both up to compare. The failed squirrel print has the exact same settings as Alalinda except for the following differences...

Squirrel - 2mm first layer, 10% fill, 5 shells, random seam

Alalinda - 3.5mm first layer, 22% fill, 2 shells, nearest seam

Those are only differences in slicing from the gcode from the current fail. My settings stayed the same for all the failed prints but I did use 3 shells, 2 shells and various amounts of fill to see if anything would work. Most of my other good prints were done with 2mm first layers as well, so I can't imagine that is the issue.

I'm going to try a couple of different fills, and see if I can find and old piece I printed from last week to compare the honeycomb quality from then with the recent Alalinda piece. Even though that print took, it still didn't seem as clean as I remember it being.

Re: Layer separation and bad infill, but perfect when hollow?

Hi Adam

I presume you mean first layer of 0.2mm (0.35mm adalinda)? 2mm and 3.5mm would be rather thick first layers.

OK, when using standard firmware the first layer must be at least 0.25mm. There really is no need to have 5 shells (2mm) skin thickness. 3 shells is usually the most you will require. I also find a 15% fill using straight lines is more than sufficient. Many items will print hollow.

I think that you should try cleaning the nozzle use this method from point 3: https://ultimaker.com/en/manuals/149-atomic-method

This will tell you if there are any restrictions in the extrude path.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Layer separation and bad infill, but perfect when hollow?

Yes, it was 0.2mm for the first layer on my print compared to the 0.35 on Adalinda. That's basically what I've printed everything at expect for the woodfill, and had no issues until this one popped up. That was after I switched to 0.35 for the first time oddly enough lol....

With the shells, I realize that but it was just the particular model I had been working with at the time. Was playing with infills and shells to get a feel for slicing different objects at different fills, etc... That said, I did a 40mm cube with 2 shells and 10% infill last night as my last print and the infill broke apart like the rest.

I did the Atomic Clean method as described, and it looks like I'm fine there. Photo isn't the greatest due to lighting, but I didn't see any red or wood attached which are the only two colors I've used aside from Grey in this nozzle since I put it on last week.

This photo really says more than anything. The one with the cut open bottom was one a print with "good" infill. Notice how the honeycomb is angular, not rounded. In all the new prints, the honeycomb starts out the same, but gets rounded as it progresses. Even with Adalinda which printed well, the fill is still rounded compared to what it would have been last week. Think that makes sense? I may try to take a quick video of it printing the first layers of the infill later today.

Re: Layer separation and bad infill, but perfect when hollow?

Adam

I was actually looking for any black bits after the clean; that would have pointed to a burnt blockage, but as you have deduced, there doesn't seem to be a problem.

So we are back to the slicing.

I believe that the situation is that when you print gcode supplied by PR, it works and when you print one that you sliced, it doesn't.?

Can I again suggest that you upload an STL that has failed, let me slice it to see if that works.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Layer separation and bad infill, but perfect when hollow?

Okay. Was able today to just fool around with the printer, and as you've suggested, it looks like it's all down to slicing. I still have no idea where I've gone wrong with things, considering I went from this....

http://www.thingiverse.com/make:194230 (sliced by me)

... to the issues you've seen with the pictures in the thread with the fill. It's just puzzling, but I'm willing to go back to the drawing board with slicing and start from scratch.

I've also cut some loops form my spools and bagged them with those packets to make sure the I'm not getting ahold of one with moisture. Decided to do that since my consistent grey starting failing along with a few other colors. Everything should have been dry, but I'm trying to think of everything I can and cross it off the list of causes.

I pulled another Prusa sliced .gcode from my PC with Marvin, and was able to print in both Bronzefill and Bamboofill with no issues at all on the fill and good looking prints. Considering I didn't tinker the the settings like colorfabb suggested, it was even more surprising they printed so well as all I did was bump the speed down a bit.

I also printed a candle holder from BioFila Silk and sliced that one myself and it turned out to be my best print yet. That said, it was the only model I tried to print that I have sliced today, so I'm not going to say the issue has been resolved just yet.

I'm going to dig through Thingiverse tonight and find something to print and slice for tomorrow. Will post the results and model file or link if it fails to see what I need to look at next. Just haven't decided what to try as my filament is getting low, but am open to suggestions if there's a certain model that would be better for this type of thing.

Re: Layer separation and bad infill, but perfect when hollow?

Adam

Don't forget that it's not impossible for there to be a fault in the slicer software. Josef has already stated that Slic3r is not good with thin-wall objects.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…