Filaflex experience

Hi all,

I currently experimenting with Filaflex, and I experience many difficulites.

- The printed objects are glued extremely strong to the PEI surface and can only be be removed by cutting with razor blades and raw force. So I now use glue stick to get a protection layer - this works better.

- Removing failed prints from the print surface seems to be way easier when I heat the bed up to 80 degree or more - this softens the Filaflex.

- The extruder often starts to jam after some minutes of extruding, and the stepper motor produces rattling noises. So , I am trying very low print speeds now, as low as 10 mm/s, and even more important, I set the retraction to 0 (accepting oozing). The back and forward retraction movements seem to f*ck up the filament.

- Too high temperatures (235° or more) did not help but produced bubbles and seems to worsen the problems.

Any other hints ?

Regards

Julian

Re: Filaflex experience

This might sound weird but the pressure of the Idler might be too tight. I print with ninjaflex and if the idler is too tight my extruder jams. Not sure what logic is behind it. Also, make sure that the filament can com out of the spool easily

Don't Slow it that much always use gluestick

Maybe do a few cold pulls with nylon if you have it to make sure you don't have any minor clogs.

let me know if it helps

Re: Filaflex experience

Having similar problem.

Tried higher temp, lower temp, lower speed.

First it actually worked for some time, but there were no settings in s3d so I experimented some. Probably got some filament inside the extruder due to retraction set in the first print.

Now I can make it feed the filament, but close after some time and need to stop the print and clean the nozzle by forcing extruder to extrude in mid air. Filament starts coming again and then clogs.

I guess that the flow is to slow and clogs. Perhaps higher speed would work? More filament throughput?

Re: Filaflex experience

I'm having a similar issue with Filaform TPU. It seems to start printing ok but after a while the extruder jams and I get a rattleing noise from the stepper motor. The things I've tried are:-

- adjusting temp

- slowing print speed down to the same speed the Prusa MK1 ran at (the Mk1 never gave me an issues at all with Flex filement)

- adjusting idle screws so the filement doesnt get squeezed to tight

I think on my MK1 printer the gap between the tube and the extruder gear was much smaller so the filement couldnt bend or jam as easily. I'm going to take the extruder apart again to see if I can move the tube up slightly.

Re: Filaflex experience

After some more testing I've managed to get a Flex print to complete without any jams or other issues.

I made the following adjustments:-

- Dusted the print bed with some Talcum Powder (this wasnt to improve the printing but it definitely helps with removal of the part after printing)

- Raised the printing temperature to 220 degrees.

- Loosened the filament idler even more. There is now an almost 1.8cm gap between the idler and the screw heads). Make sure the filament isnt squashed against the extruder gear too much.

- Made sure the filament was coming off the roll as easily as possible and wasnt sticking. I actually unwound a few meters and then wound it back on loosely.

- slowed printing down to the same speed the MK1 ran at for Flex material.

- hange retraction settings to match what was set on the MK1 for Flex material.

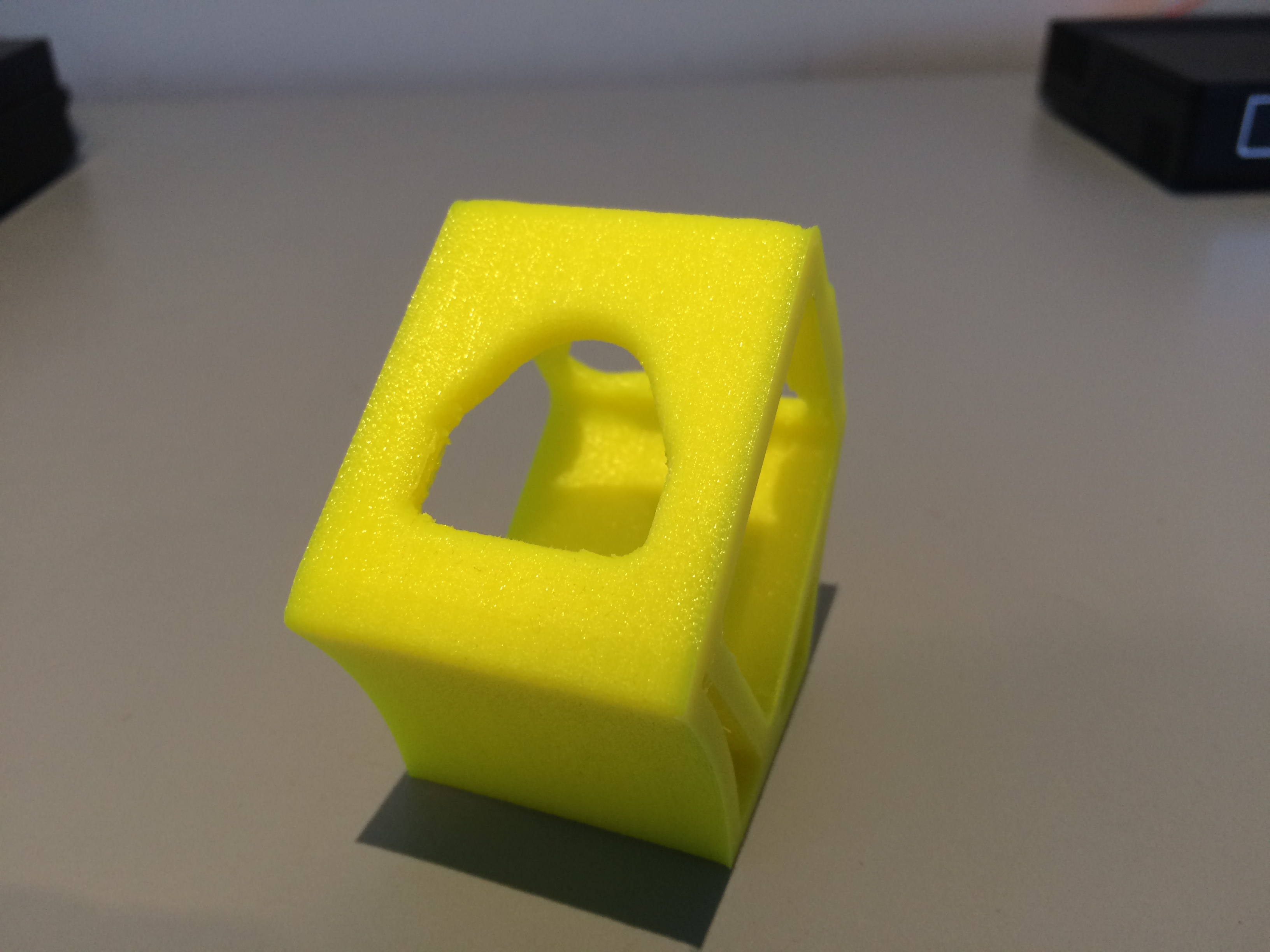

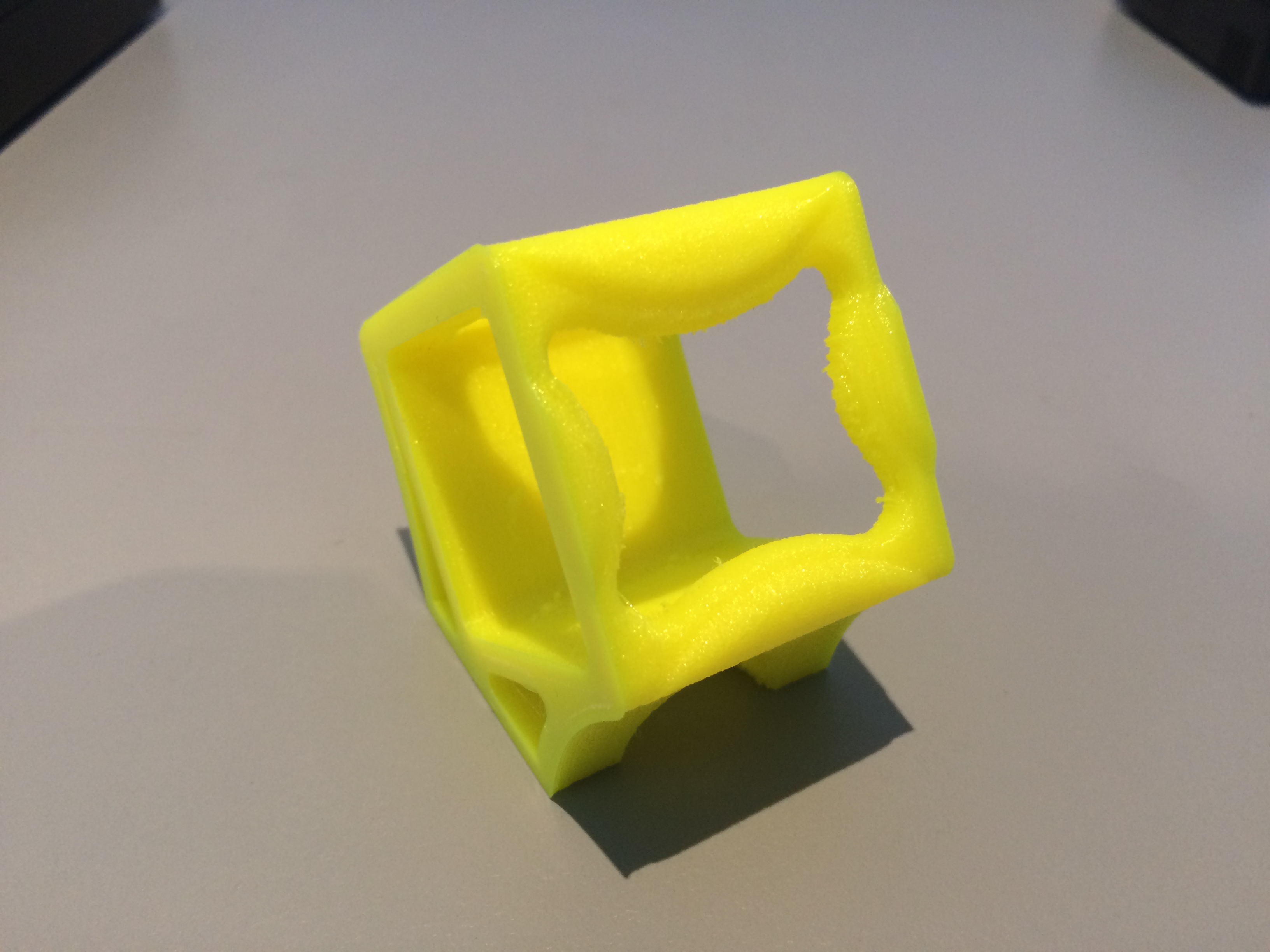

The result can be seen in the attached photos.

I use Simplify3D for this print. I'll post the setttings file later today when I get home.

Re: Filaflex experience

Here are my Simplify3D settings.

Re: Filaflex experience

Thanks for the S3D settings!

Re: Filaflex experience

looks like you got good results

Re: Filaflex experience

Yeah the result wasnt too bad.

I've since done another print making some adjustments to the Extrusion Multiplier (dropped it to 0.98) which cut down the oozing while still getting nice layers. I still have to adjust the Z-Height a little more so the first layer isnt as squashed but its getting close to being right.

The thing that made the biggest difference was making the idler nice and loose and also making sure the filament comes of the spool nice and easy.

I'll also be using glue stick on the bed from now on. Talcum Powder does make parts easier to remove but it can still be very difficult. Glue Stick will be much better and its what I've always used in the past so I know its works well.