Dialed in at one layer height but not another

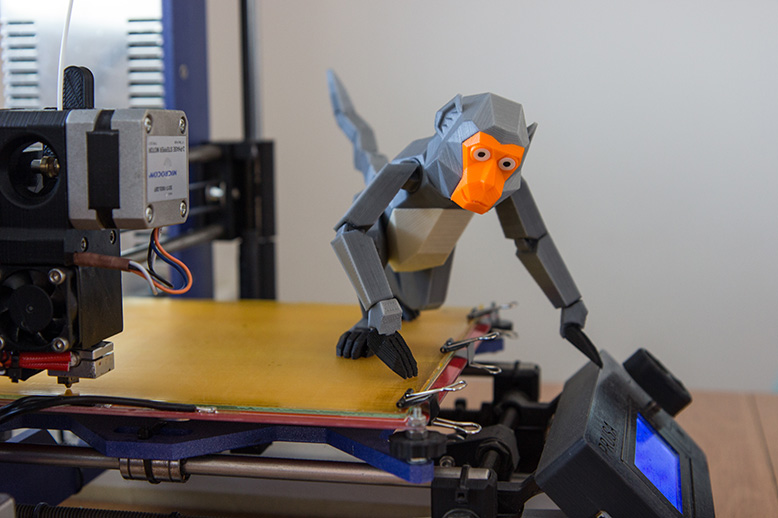

Using a hardened 0.4mm nozzle from E3D, I am dialed in and pumping out some pretty consistent prints at 0.2 , 0.15 and even one print at 0.1 just to see how it worked. However I consistently suffer with horizontal layers that don't overlap and leads to pillowing and really poor subsequent layers. so all my first layers are at 0.2 and look great with awesome adhesion, then subsequent layers are whatever I have chosen for my print.

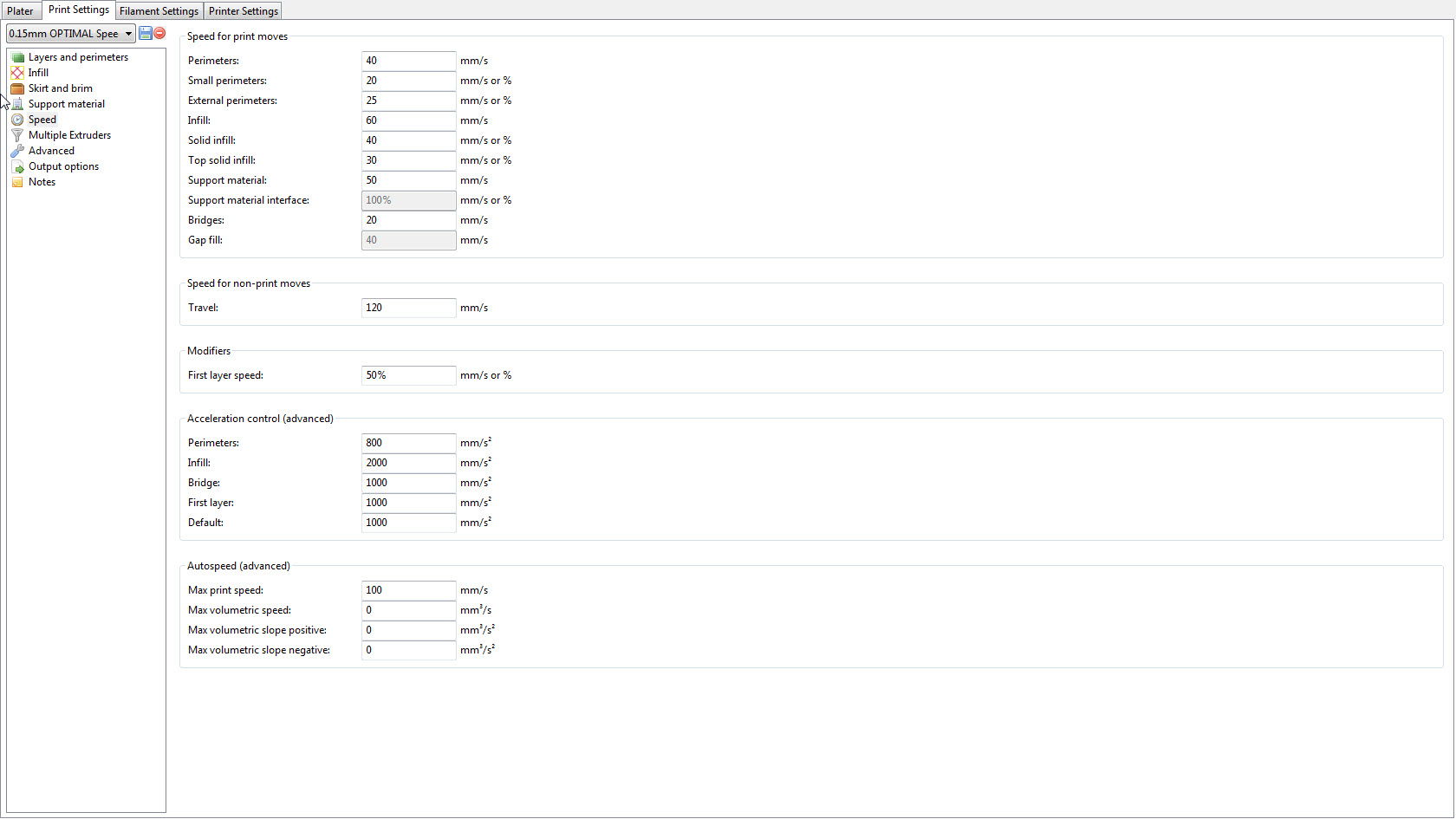

just to be clear, when I choose a print layer height I either choose it from the predefined print settings on the first Tab "Plater" in SLic3r where it gives me several predefined options. Or I choose the Print Settings Tab and manually change the height there.

I see no difference between my prints regardless of where/how i choose the height. if I choose 0.35 however, I get the issues I mentioned earlier where the layers seem inconsistent and do not seem to touch. I have dialed my extrusion in for the filament I am using but I haven't made changes for different layer heights as I didn't think it was necessary. I do see extrusion width under the advanced heading but in Slic3r it doesn't change regardless of the layer height I choose. They all say the same 0.42-0.45 defaults. Shouldn't the width change with various layer height?

So my 1st question is why do I have awesome prints at 0.2 and below but suffer at 0.35mm?

2nd question is if I wanted to drop down on nozzle size do I need to change my extrusion width since it doesn't look like Slic3r is going to adjust it for me? if so what's a good rule for matching it to the nozzle to layer height and the various extrusion width parameters in Slic3r? I had read 80% of nozzle diameter is max layer height. but I haven't seen any suggestions about extrusion width or other things that need to change going up or down in nozzle size.

I have a 0.8mm nozzle I was going to test and was using the numbers from the 0.25 layer height 0.4mm nozzle combo to figure out a ratio of nozzle:width and nozzle:height to apply to the 0.8 but every time I made a change to the 3rd option "extrusion width perimeters" slic3r crashes on me so I gave up and never installed the nozzle.

Thanks for any help you can give me

Re: Dialed in at one layer height but not another

I had read 80% of nozzle diameter is max layer height

This statement answers question 1. I'm not sure why Prusa decided to add a .35mm layer height preset in Slic3r but in my opinion they should have made it for .30mm. If I go above .30mm with a .4 nozzle I get the same issues as you.

Max width should be no more than 120% of nozzle size. For a .25mm nozzle that would come out to .30 for layer width.

Re: Dialed in at one layer height but not another

Awesome thank you

Re: Dialed in at one layer height but not another

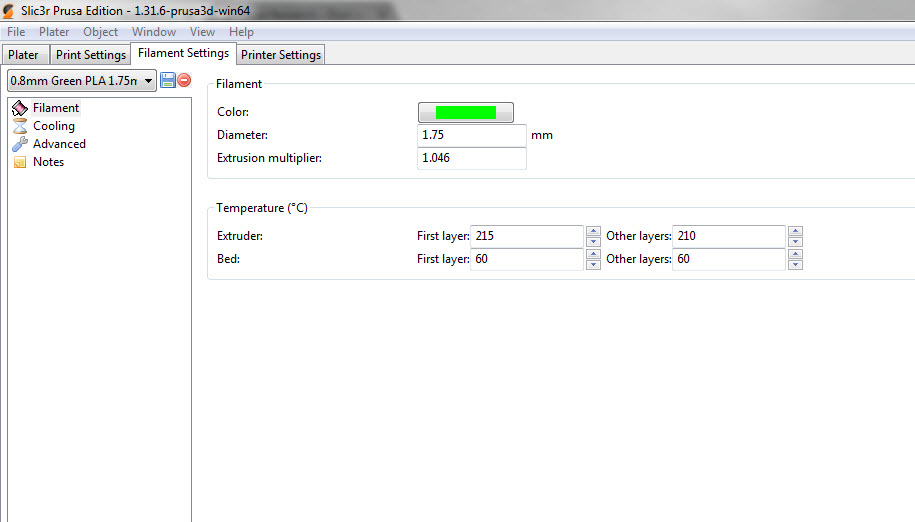

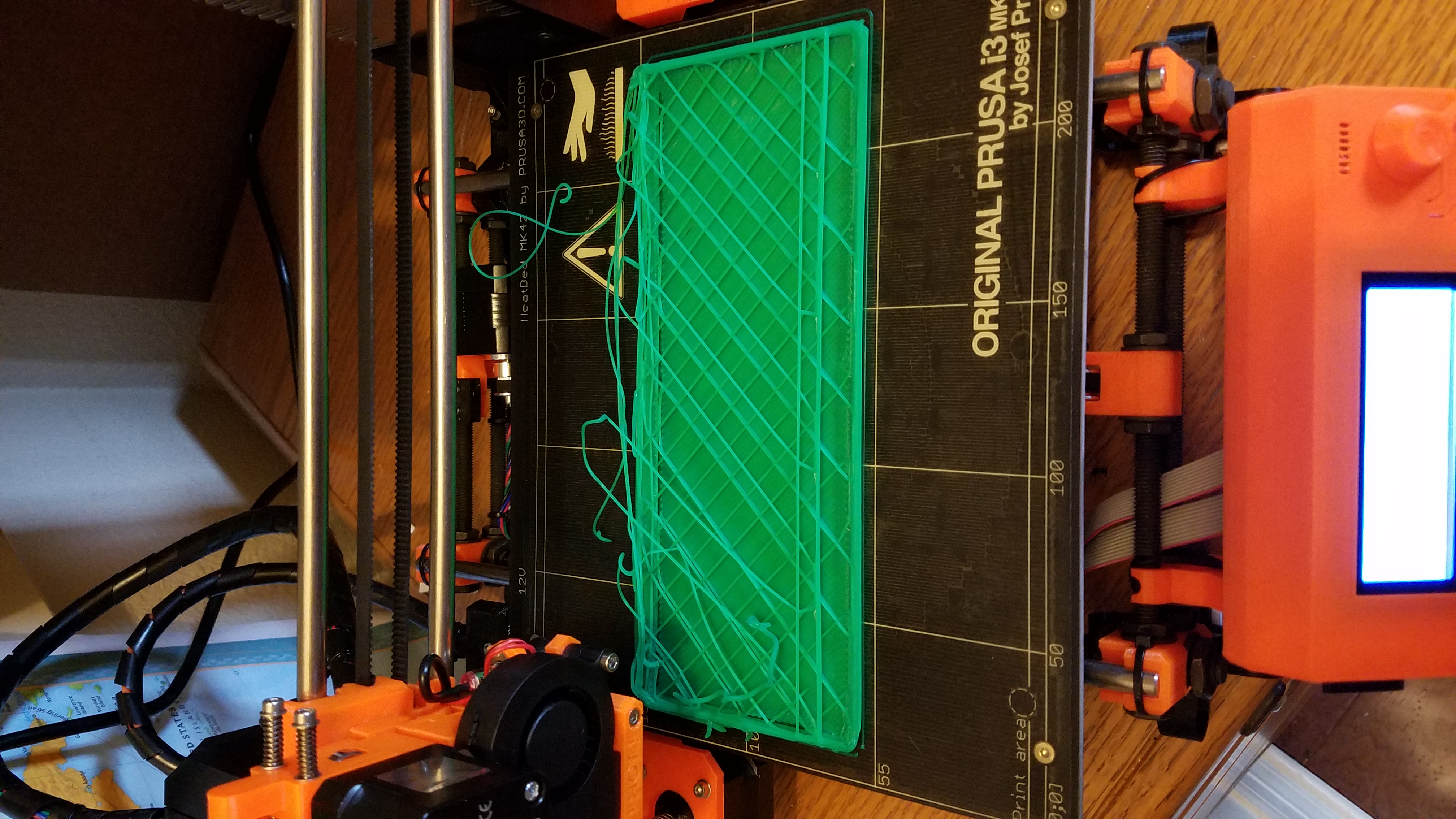

Ok so here are my settings for the 0.8 nozzle so far and first later went down great but next 2 perimeters were essentially into thin air. they laid down nice but didn't stick to themselves or to the bottom layer. subsequent infill layer went down nicely. but as the model builds I don't see how it will hold since it's not attached at the bottom.

Re: Dialed in at one layer height but not another

suggestions? didn't have to deal with all this with smaller nozzles.

Z-height is adjusted but my understanding is that only applies to 1st layer anyway.

if it helps here is the g-code that slic3r generated for the object

i took out most of the coordinates to get it to allow me to post the code

======================================================

; generated by Slic3r 1.31.6-prusa3d-win64 on 2017-01-22 at 14:16:23

; external perimeters extrusion width = 1.00mm

; perimeters extrusion width = 0.94mm

; infill extrusion width = 1.00mm

; solid infill extrusion width = 1.00mm

; top infill extrusion width = 0.95mm

M107

M115 U3.0.9 ; tell printer latest fw version

M83 ; extruder relative mode

M104 S215 ; set extruder temp

M140 S60 ; set bed temp

M190 S60 ; wait for bed temp

M109 S215 ; wait for extruder temp

G28 W ; home all without mesh bed level

G80 ; mesh bed leveling

G1 Y-3.0 F1000.0 ; go outside pritn area

G1 X60.0 E9.0 F1000.0 ; intro line

G1 X100.0 E12.5 F1000.0 ; intro line

G21 ; set units to millimeters

G90 ; use absolute coordinates

M83 ; use relative distances for extrusion

G1 E-0.80000 F2100.00000

M204 S1000

G1 E-0.80000 F2100.00000

G1 Z76.000 F6000.000

M107

G4 ; wait

M104 S0 ; turn off temperature

M140 S0 ; turn off heatbed

M107 ; turn off fan

G91 ; relative movements

G1 F150 ; slow Z rate

G1 Z15 ; Z up 15mm

G90 ; back to absolute

G1 X0 Y200 Z30; home X axis

M84 ; disable motors

; filament used = 105275.0mm (253.2cm3)

; avoid_crossing_perimeters = 0

; bed_shape = 0x0,250x0,250x210,0x210

; bed_temperature = 60

; before_layer_gcode =

; bridge_acceleration = 1000

; bridge_fan_speed = 100

; brim_width = 0

; complete_objects = 0

; cooling = 1

; default_acceleration = 1000

; disable_fan_first_layers = 1

; duplicate_distance = 6

; end_gcode = G4 ; wait\nM104 S0 ; turn off temperature\nM140 S0 ; turn off heatbed\nM107 ; turn off fan\nG91 ; relative movements\nG1 F150 ; slow Z rate\nG1 Z15 ; Z up 15mm\nG90 ; back to absolute\nG1 X0 Y200 Z30; home X axis\nM84 ; disable motors

; extruder_clearance_height = 20

; extruder_clearance_radius = 20

; extruder_offset = 0x0

; extrusion_axis = E

; extrusion_multiplier = 1.046

; fan_always_on = 1

; fan_below_layer_time = 100

; filament_colour = #00FF00

; filament_diameter = 1.75

; filament_max_volumetric_speed = 0

; filament_notes = "List of materials tested with standart PLA print settings for MK2:\n\nEsun PLA\nFiberlogy HD-PLA\nFillamentum PLA\nFloreon3D\nHatchbox PLA\nPlasty Mladeč PLA\nPrimavalue PLA\nProto pasta Matte Fiber"

; first_layer_acceleration = 1000

; first_layer_bed_temperature = 60

; first_layer_extrusion_width = 0.94

; first_layer_speed = 50%

; first_layer_temperature = 215

; gcode_arcs = 0

; gcode_comments = 0

; gcode_flavor = reprap

; infill_acceleration = 2000

; infill_first = 0

; layer_gcode =

; max_fan_speed = 100

; max_print_speed = 100

; max_volumetric_extrusion_rate_slope_negative = 0

; max_volumetric_extrusion_rate_slope_positive = 0

; max_volumetric_speed = 0

; min_fan_speed = 85

; min_print_speed = 15

; min_skirt_length = 4

; notes =

; nozzle_diameter = 0.8

; only_retract_when_crossing_perimeters = 0

; ooze_prevention = 0

; output_filename_format = [input_filename_base].gcode

; perimeter_acceleration = 800

; post_process =

; pressure_advance = 0

; resolution = 0

; retract_before_travel = 1

; retract_layer_change = 1

; retract_length = 0.8

; retract_length_toolchange = 3

; retract_lift = 0.5

; retract_lift_above = 0

; retract_lift_below = 199

; retract_restart_extra = 0

; retract_restart_extra_toolchange = 0

; retract_speed = 35

; skirt_distance = 2

; skirt_height = 1

; skirts = 1

; slowdown_below_layer_time = 25

; spiral_vase = 0

; standby_temperature_delta = -5

; start_gcode = M115 U3.0.9 ; tell printer latest fw version\nM83 ; extruder relative mode\nM104 S[first_layer_temperature] ; set extruder temp\nM140 S[first_layer_bed_temperature] ; set bed temp\nM190 S[first_layer_bed_temperature] ; wait for bed temp\nM109 S[first_layer_temperature] ; wait for extruder temp\nG28 W ; home all without mesh bed level\nG80 ; mesh bed leveling\nG1 Y-3.0 F1000.0 ; go outside pritn area\nG1 X60.0 E9.0 F1000.0 ; intro line\nG1 X100.0 E12.5 F1000.0 ; intro line

; temperature = 210

; threads = 4

; toolchange_gcode =

; travel_speed = 100

; use_firmware_retraction = 0

; use_relative_e_distances = 1

; use_volumetric_e = 0

; wipe = 0

; z_offset = 0

; dont_support_bridges = 1

; extrusion_width = 0.94

; first_layer_height = 0.5

; infill_only_where_needed = 0

; interface_shells = 0

; layer_height = 0.6

; raft_layers = 0

; seam_position = nearest

; support_material = 0

; support_material_angle = 0

; support_material_buildplate_only = 0

; support_material_contact_distance = 0.1

; support_material_enforce_layers = 0

; support_material_extruder = 1

; support_material_extrusion_width = 0.35

; support_material_interface_extruder = 1

; support_material_interface_layers = 0

; support_material_interface_spacing = 0

; support_material_interface_speed = 100%

; support_material_pattern = rectilinear

; support_material_spacing = 1.5

; support_material_speed = 50

; support_material_threshold = 40

; support_material_with_sheath = 0

; xy_size_compensation = 0

; bottom_solid_layers = 2

; bridge_flow_ratio = 0.95

; bridge_speed = 20

; ensure_vertical_shell_thickness = 1

; external_fill_pattern = rectilinear

; external_perimeter_extrusion_width = 1

; external_perimeter_speed = 50

; external_perimeters_first = 0

; extra_perimeters = 0

; fill_angle = 45

; fill_density = 5%

; fill_pattern = rectilinear

; gap_fill_speed = 40

; infill_every_layers = 1

; infill_extruder = 1

; infill_extrusion_width = 1

; infill_overlap = 25%

; infill_speed = 50

; overhangs = 0

; perimeter_extruder = 1

; perimeter_extrusion_width = 0.94

; perimeter_speed = 50

; perimeters = 2

; small_perimeter_speed = 40

; solid_infill_below_area = 0

; solid_infill_every_layers = 0

; solid_infill_extruder = 1

; solid_infill_extrusion_width = 1

; solid_infill_speed = 50

; thin_walls = 0

; top_infill_extrusion_width = 0.95

; top_solid_infill_speed = 50

; top_solid_layers = 2

Re: Dialed in at one layer height but not another

OK. i tried at higher temps (222) did same thing. got to looking at the model and it has a gradual slope to the front of the object and with the 0.5 and 0.6mm jumps it was leaving a big gap that wasn't able to be bridged.

I'm hoping that was the problem. I dropped the first few layers down to a reasonable 0.3 height and now I'm reprinting the curved portion at 0.3 and the remainder at 0.6

I'll update as it plays out.

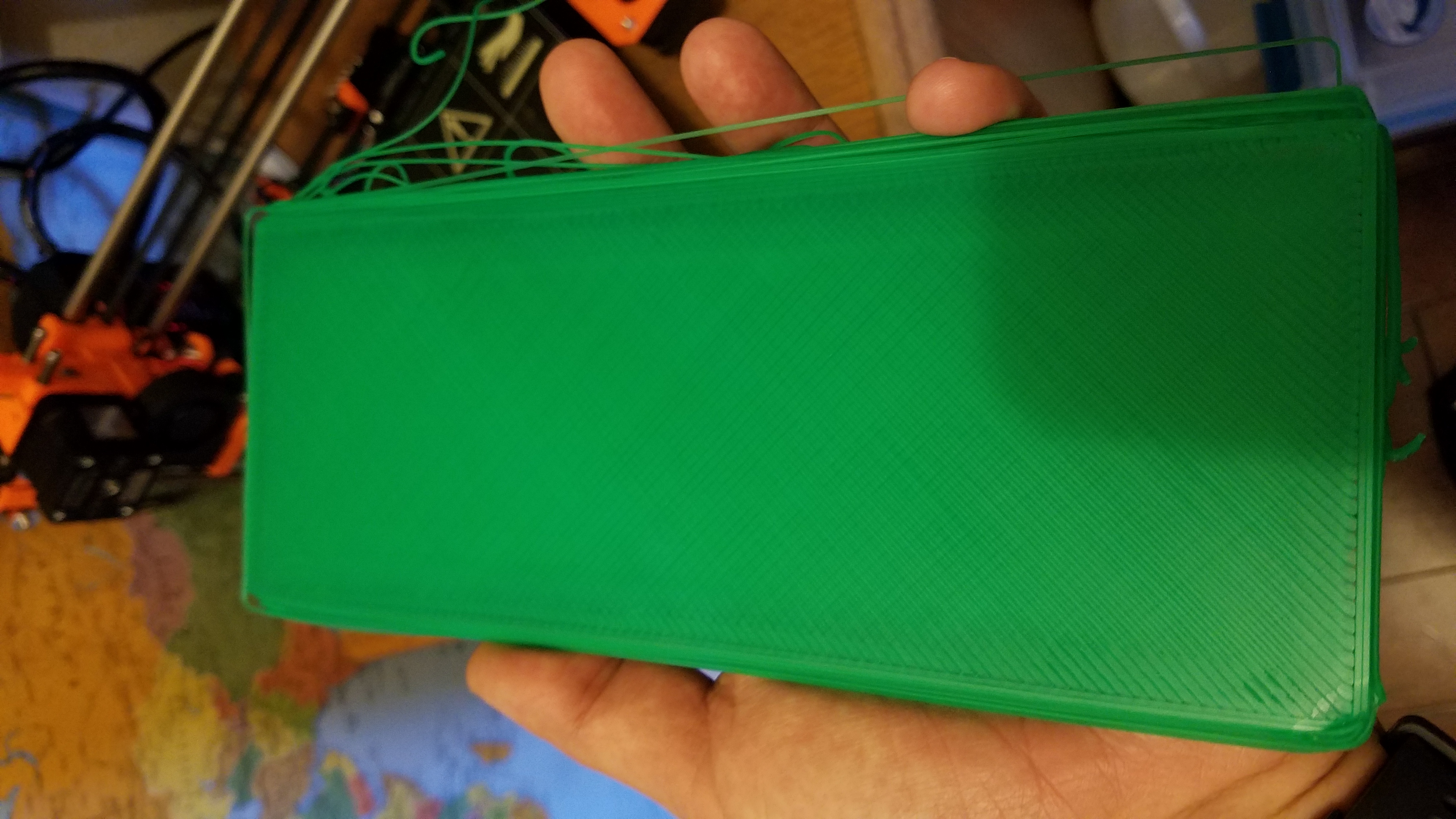

In the meantime I printed a 25x25 block at 0.5 with 5% infill and it printed great so I think it's the model

Re: Dialed in at one layer height but not another

Glad it's working but I think a 0.8 nozzle may be pushing too far past the limitations imposed by the standard E3D hotend. Anything over 0.6 and I would look into the Volcano hotend as it has a much longer heated block to push filament through.

Re: Dialed in at one layer height but not another

Good to know. I'm printing a larger object so I figured it would be a good time to try and troubleshoot the 0.8, I'm looking to confirm shape and dimensions it's far from a final output so I figured if I could shave a few hours off the print by pushing it through the 0.8 it might be worth it.

I've got a 0.6 as well. I could play with later.

I don't have any detailed items yet to justify hooking up my 0.15 or 0.25 nozzles yet.

Re: Dialed in at one layer height but not another

Hi Pedaldoc,

Is it possible to print the first few layers at a lower layer height to get over the slope then switch to a greater layer height for the rest of the build. I do something like this for larger builds although I dont use the 0.8 nozzle... my need is for higher density fill at the top and bottom of the print.

regards joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Dialed in at one layer height but not another

that is exactly what I did.

here's the instructions. pretty easy to do