Base of ABS small pulleys hard to get good

I've got a small pulley hard to print with ABS.

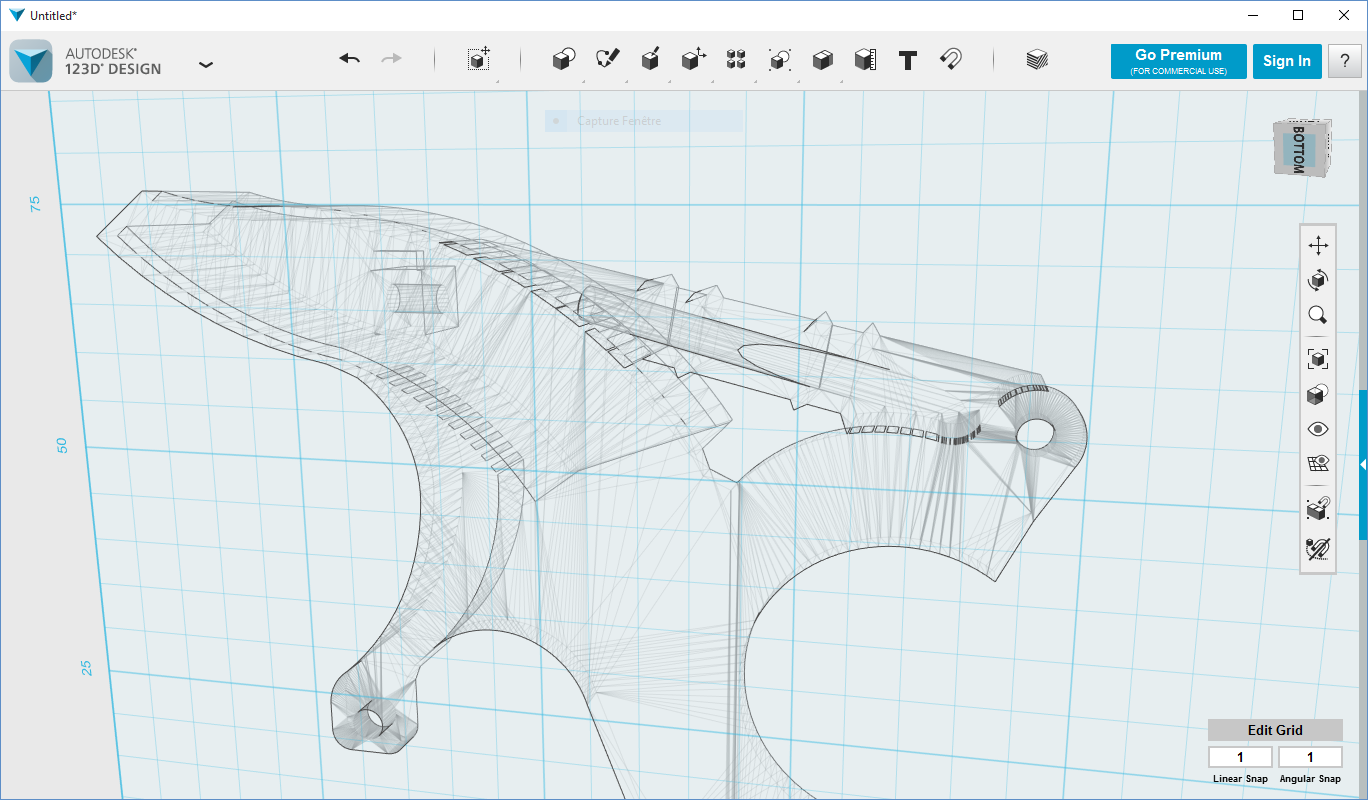

This is the pulley, the width of the base is 3*0.45mm large, Height is 14mm ans outer diameter is 22mm:

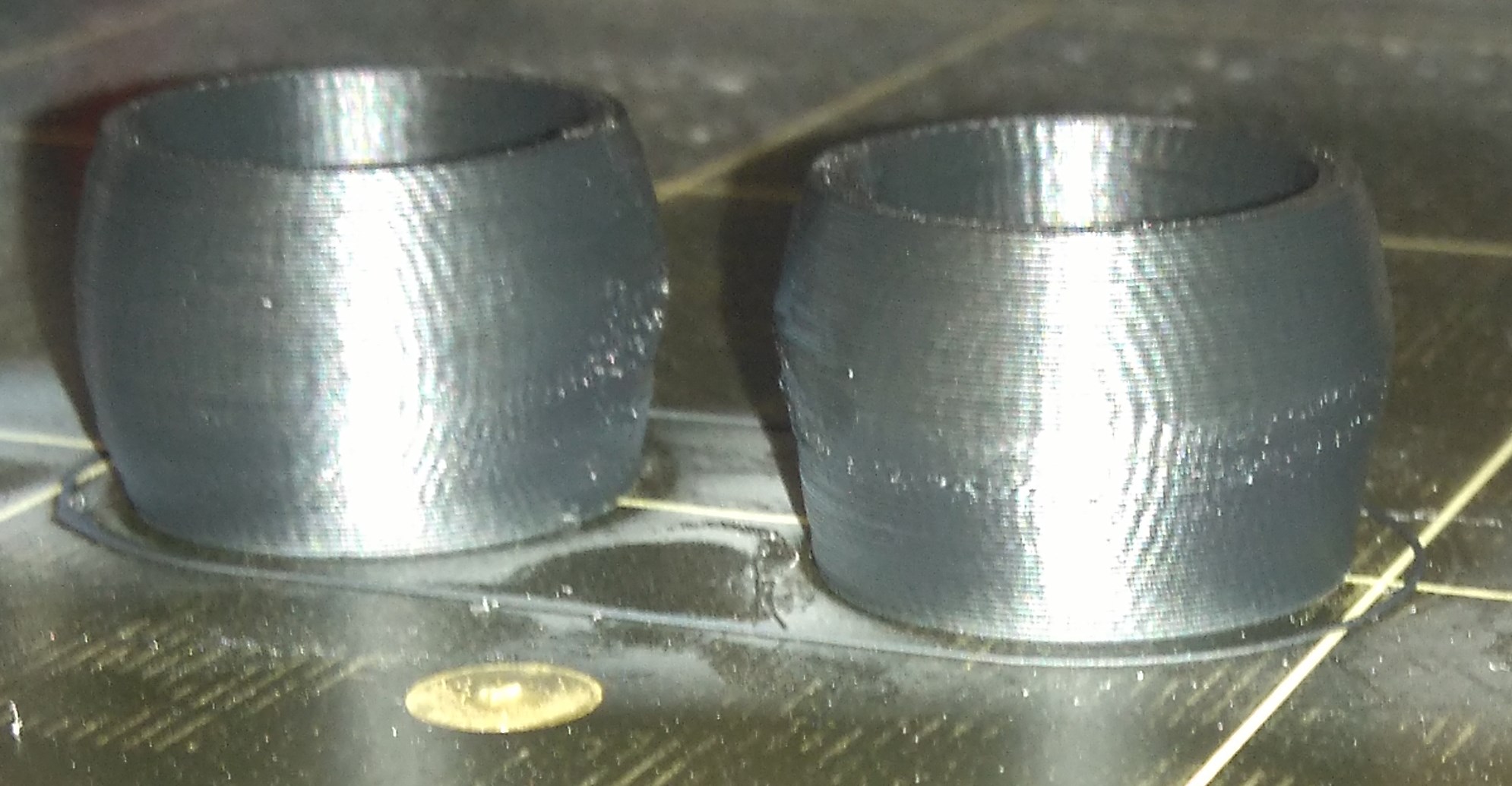

1. I managed to print well 2 pulleys one month ago. I tried again few days ago and the base was horrible (same gcode file, same material). I'm disappointed. The pulley printed on the left is better than the one on the right of the bed.

2. I then made some tries.

- increasing number of pulleys per batch improve result. If I print 10 at once, I got 2 to 3 out of my requirements and all have a base with a smaller diameter on the 2 millimeters.

- the top is perfect in anycase.

Now the parameters are:

Infill: 100% concentric

Speed: 40

Material: FuturaForm EasyABS 220°C-270°C temp range (tried Prusa ABS but worst in that case)

Temp: 270°C first layer / 250°C next

Bed: 100°C

Cooling: 10 to 30% fan, disabled on the 3 first. Slow down if layer time is below 5s.

No case around the printer

What I would like is to be able to print only two good one at a time, not ten.

Advises? Idea what's happens? Why so much shrinking at the base and less at the top?

Re: Base of ABS small pulleys hard to get good

The issue you are probably facing is that the filament does not have time to coll down before additional layer is printed on it. That would explain why it's printing fine when you are printing multiple object and issue when you are priting a single one.

There are two option to fix that:

1 - print it with other object, that will make layer time longer and let time for the layer being printed to cool down.

2 - use moderate fan during print (something below 30 %)

3 - Rely on the automatic slowdown setting in Slic3r to automatically slow down small layer, with very small fan activity (it's in the cooling section)

4 - Probably use colder temperature, try doing down to 230~240 °C

I'm like Jon Snow, I know nothing.

Re: Base of ABS small pulleys hard to get good

First I'm happy that a guru answer my request (I'm a 2 months beginner).

1. I won't print other bigger object as I don't need just to be sure that it is possible to print with ABS. But it could be an interesting point to design a bench to study the minimum time to cool down between each layers. Or perhaps there is already a bench I'm not aware of. I will probably go this way but later due to time management.

2. OK I will increase fan speed. I think that there is at least 2 very obscur notions. It is belt tension (this tension is OK, that is not, but what unit?) and fan speed in percentage. In 3D printing there is a lot to do. It is exciting.

3. I already done that, I set "Slow down if layer time is below 5s.". But it seems not enough. I should be at an extreme working point of the machine for ABS. I don't know how to push further in that direction except by slowing down the printing speed. Perhaps the minimum printing speed of 5mm/s is too much compare to the cooling down and it is not possible to print only 2 parts. If I have to print 2, I have to print a big part on the bed at the same time for the pulleys to cool down. It seems there is no more advanced settings in new slic3r to cover that case.

4. I will set the noozle to lower temp.

PETG is good and versatile, no issues. But I need ABS for that part.

My next tries could be a few couple of days later.

Re: Base of ABS small pulleys hard to get good

Hi,

just an addition: 5 second is too fast for minimal layer time, I would go to 30 seconds instead.

(And I'm not a guru, knowing that failing is learning, I learned a lot 😉 )

I'm like Jon Snow, I know nothing.

Re: Base of ABS small pulleys hard to get good

Problem is that minimum print volume will override the minimum layer time.

As Christophe says, you need each layer to take at least 30 seconds, so you will have to print multiple objects to achieve that - or you could print a "prime tower" instead of additional objects, just to increase layer time.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Base of ABS small pulleys hard to get good

Thanks. My thinking of the layer time in Slic3r was totally wrong. Indeed, 5s is far too little. 😳

I didn't have time to go deeper on that as I don't print ABS since.

The few tries I done go well with 60s. I increased the temperature to avoid delamination.

Need more tries to find good parameters. I think there is still issues with fan blow over small surface of ABS, it is better to send the extruder elsewhere on the bed between layers.