Advice on printing a (very thin) hairspring

I recently got my MK3 and it's my first 3D printer, so I'm still heavily learning. But so far I'm quite happy with the results and the printer produces good quality even on some trickier parts.

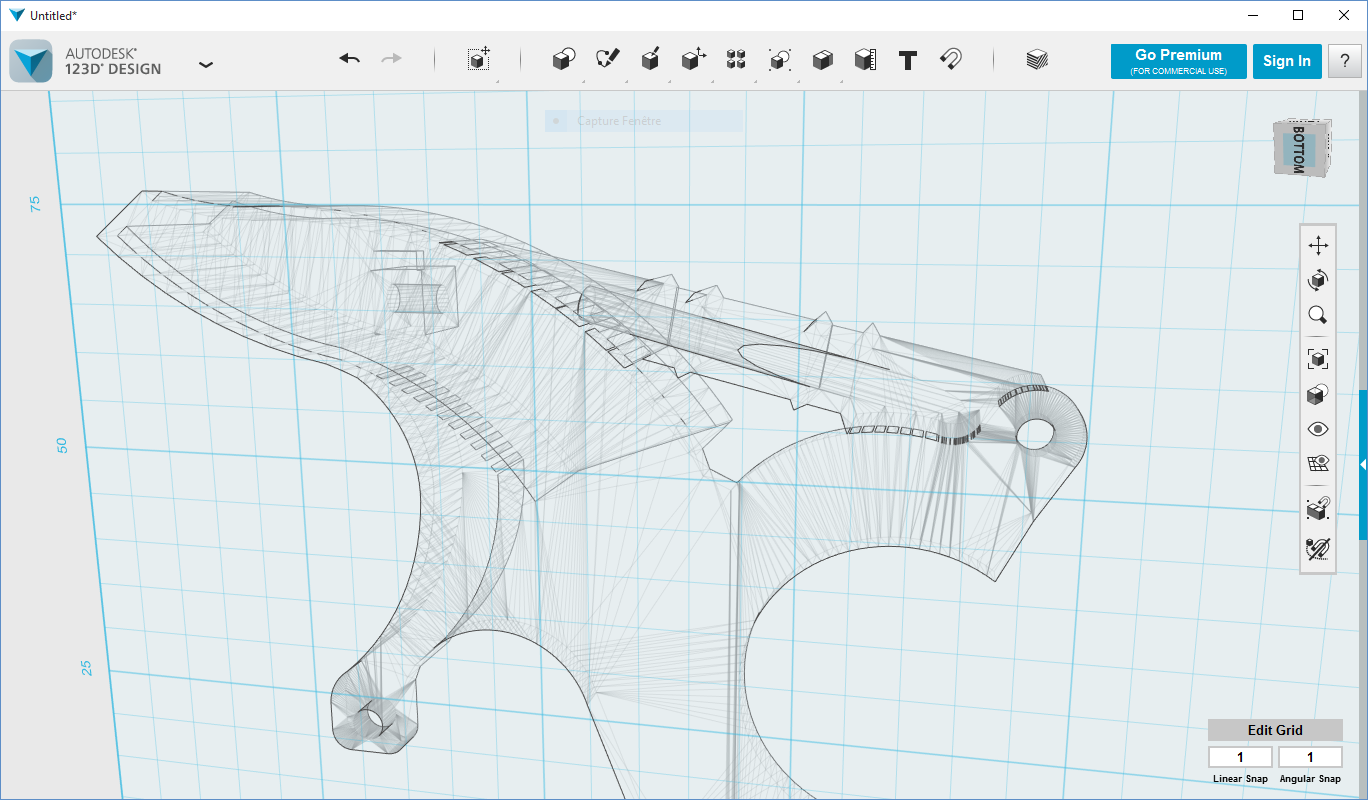

There is one challenging part that I'm experimenting with right now. It's a clock-style flat hairspring:

The main challenge of course being that it's so thin, but still needs fairly accurate geometry and decent mechanical strength. I suspect that ideally you'd print this in something else than PLA and with a smaller nozzle, which is probably what I'll end up doing. But for now I want to see how good it can get with PLA and the standard 0.4mm nozzle.

So I'm looking on advice on Slic3r (Prusa edition) settings that can handle this part in a decent way. So far I've tried 0.1mm and 0.15mm standard settings, but all 4 prints (I even tried different spools of PLA) have failed, and moreover they have failed in the exact same way. It seems to go quite well for the first 50%, up to roughly 1.25mm height. What happens then is due to material build-up in the area of the two 45deg kinks in the outermost spiral. The nozzle finally hits the area and causes the outermost spiral to lose adhesion to the plate and the following layers are shifted in X/Y, resulting in a very ugly outer spiral...

I've attached the STL if anyone wants to give it a try. But really I'd just be happy for any input whatsoever.

Cheers,

/Joel

Re: Advice on printing a (very thin) hairspring

I am having a go at the moment. I am using 0.2mm layer height and have dialled down both speed and acceleration. It is only to 1.4mm at the moment but I can already see the problem points at the sharp 45deg and 90deg bends.

Linear advance when it is re-enabled would solve the bulging. I would however recommend radiusing those bends. The 45deg one a 1.00mm radius should do. The 90deg one is more of a problem due to space constrains and I would try a 0.5mm radius.

I'll post again when the print finishes and weather it succeeded to the end and my actual settings if it did.

Martin

Martin Wolfe

Re: Advice on printing a (very thin) hairspring

It. printed! 🙂

There are still problems with the 45deg bends but it got through it.

Settings used:-

*Extruder fitted with a sock*

Filament: Sunlu PLA+

First layer: 205°C / 60°C

Other layers: 195°C / 60°C

*Note: When I had the supplied Prusa Silver PLA I used the default settings and a sock

Layer Height: 0.20mm

Printer Settings:

Retraction speed: 50mm/s (Up from the default 35mm to reduce stringing from the Sunlu PLA+ filament)

Print Settings/Layers:

Layer height 0.2mm

First layer height 0.2mm

Print Settings/Speed for print moves:

Perimeters 20mm/s

Small perimeters 15mm/s

External perimeters 20mm/s

Print Settings/Speed for non-print moves:

Travel 100mm/s

Print Settings/Speed Acceleration control (advanced)

Perimeters 100mm/s²

First layer 100mm/s²

Default 100mm/s²

As I have to change to PETG for my next print I will run a test in that and see how it goes as the spring is very floppy in PLA+

Martin

Martin Wolfe

Re: Advice on printing a (very thin) hairspring

PTEG printed.

The was a small problem. The print crashed during the last layer but auto home worked and it resumed without any layer shifting. The resulting blob was cut away with an exacto knife then filed flat.

Posibly your problems were caused by layer changes as well. Printing in vase mode should eliminate that.

Martin

Martin Wolfe

Re: Advice on printing a (very thin) hairspring

Well I have finished my planed PETG print so I am now printing it in vase mode in PETG before I put my usual PLA+ back in the printer. Started from the 0.2mm FAST Mk3 print settings and the only change I made was to vase mode. Only just started but it looks very good.

Martin

Martin Wolfe

Re: Advice on printing a (very thin) hairspring

Wow, thank you so much for your extensive advice Martin! I'll try your settings right away, yours look way better than the ones I printed 🙂

As a noob, I have no idea what you mean by *Extruder fitted with a sock*....

Re: Advice on printing a (very thin) hairspring

Hi Joel,

Just try vase mode in 0.20mm. That was the critical for the perfect print. Although the other settings made it printable they were not as good.

An explanation as to what a sock is.

When I started the draft from the print fan was causing me troubles dialling in the best filament settings. A sock protects the hot end heater block and nozzle from the print fan so it now only cools the work piece (the filament when bridging as well) as intended.

Regards,

Martin

Martin Wolfe

Re: Advice on printing a (very thin) hairspring

I tried vase mode in 0.20mm with the Prusa stock Silver PLA. The result was near perfect! I say "near" perfect because a small blob formed in the first layer, roughly in the middle of the largest diameter section after the 45deg bends. But it's barely visible now that it finished and the 45deg section looks flawless!

Here's a comparison between one of my failed prints and the last one:

Again, thank you very much for your effort!

I might give the sock thing a try then, especially since it seems really affordable.

Just out of curiosity - what would be your material of choice for a spring like this?

Also, do you think there's any way to control the thickness of the coil? Right now it's basically given by the thickness of one perimeter, but maybe a smaller nozzle could be interesting.

/Joel

Re: Advice on printing a (very thin) hairspring

Well material of choice would all depend on how stiff you want it. I would use PETG. The stiffer materials need and enclosure to print reliably.

Working from floppy to hard:-

TPU for soft and rubbery

PLA+ not that stiff

PLA stiffer

PETG a bit stiffer still

HIPS/ABS next up (Personally I would avoid ABS for toxicity reasons and stick to HIPS)

Polycarbonate

Carbonyte

The Ridgid-Ink site has a guide to the various filaments.

As far as I am aware there is no way to control the thickness of the coil although you may be able to go up to 1.6mm thick. Vase mode has a thickness of two perimeters. But if you really want it stiffer just make it taller.

Martin Wolfe

Re: Advice on printing a (very thin) hairspring

Just so you know I am a noob as well. Got my MK3 my first 3D printer as a kit mid Feb.

Martin

Martin Wolfe

Re: Advice on printing a (very thin) hairspring

Great, thanks for the advice!