The dreaded Bondtech click and Flow setting

Hi 1st printer user here.

Trying some longer prints I've started getting the clicking/skipping gear movements and subsequently failed prints. A bit annoying because it's happening 1, 2 or even 3 hrs in (using Prusa PLA)

I've tried adjusting: nozzle temp +-5 deg - no effect, +- idler screws - no effect

Now what seems to work is increasing my Flow from 95 to 100.

Can an experienced user suggest why this could be happening

Re: The dreaded Bondtech click and Flow setting

Self assembled or pre assembled.

How well meshed are the gears - did you get the grooves aligned properly as it is a bit of a fiddle - you sure the tension screws are into the nuts and evenly tightened - you sure the gear isn't loose on the stepper shaft it shouldn't be possible for it to skip gears unless the tensioner is way too loose.

Re: The dreaded Bondtech click and Flow setting

Self-assembled.

I'm pretty sure the gears tension and the alignment are fine, had success with some flexible filament samples. The click comes as the gears seem to be trying to force the filament through faster than the filament can take it if that makes sense

Re: The dreaded Bondtech click and Flow setting

The last filament should have read extruder

Re: The dreaded Bondtech click and Flow setting

If the tensioner etc is OK and the extruder can't cope with the speed the temperature is too low - or the speed to high - the two work side by side, what are you trying to print and at what speed / temperature wouldn't want to be going faster than 15 to 20mm/s with flex.

Re: The dreaded Bondtech click and Flow setting

Seemed to me like the click was happening when the extruder shifted direction quickly.

Re: The dreaded Bondtech click and Flow setting

If the tensioner etc is OK and the extruder can't cope with the speed the temperature is too low - or the speed to high - the two work side by side, what are you trying to print and at what speed / temperature wouldn't want to be going faster than 15 to 20mm/s with flex.

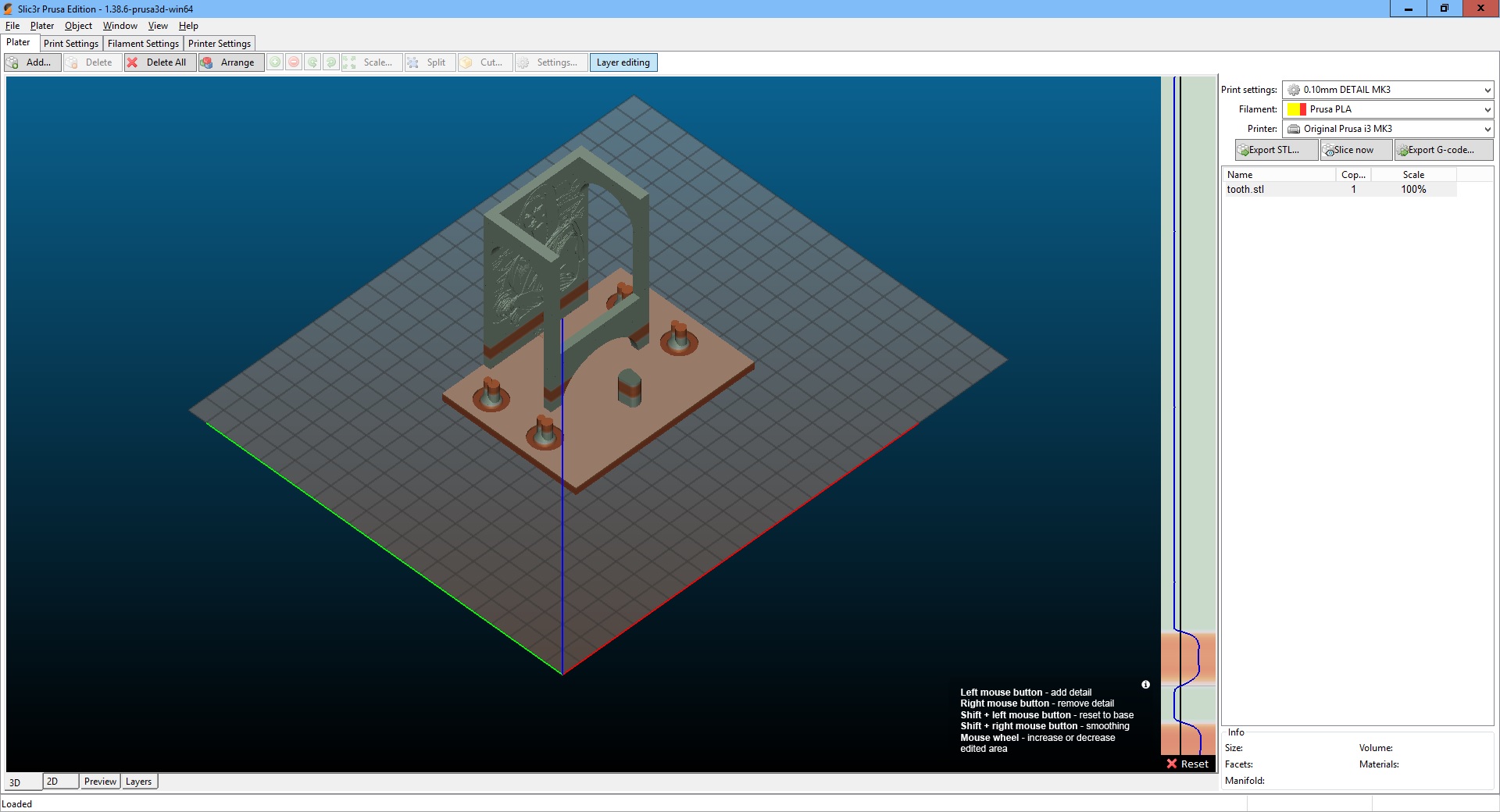

Hi using Prusa PLA. Here's what I've been tring to print. The clicking seems to only occur during the 0.05 sections

Re: The dreaded Bondtech click and Flow setting

A failed and overheating filament sensor can also cause this as it makes the plastic too soft to be effectively extruded. Touch the top of the extruder (near where your filament enters the machine) - if it's very hot you might be experiencing this.

Re: The dreaded Bondtech click and Flow setting

my bet would be retraction, you are retracting for a long time during the moves to those parts and if it is retracted far enough it may move out of the heat zone and, slick/click when it tries next to deliver filament. my guess also might be that the part cooling fan is cooling off the nozzle. try turning down retraction, turn up temp and turn the fan down.

Re: The dreaded Bondtech click and Flow setting

Thx to all trying to help and I will go through each suggestion.

In the meantime I've tried to test the tensioning and think that can be ruled out. From what I can tell it seems to be a function of the time the printer is running with something slowly degrading. The model is a simple hollow cone sliced in the latest version of Slic3r PE with no changes in the basic settings. Each test was run following an unload/reload routine. Could it be a partial block to the extruder that over time is strangling the flow of filament?

Re: The dreaded Bondtech click and Flow setting

My guess is that the bondtech extruders with 1.8° steppers just cannot extrude at a resolution high enough as it is needed for 0.05 or even 0.1 mm layer height at a 0.4 mm nozzle for small objects. The bondtech have a resolution of 140 steps per mm.

After some calculation, at a layer height of 0.05 mm and with a nozzle of 0.4 mm, the extruder extrudes at a rate of 0,37 steps per cylinder (think of it as one circle with the given layer height, 0.4 mm diameter, just like when the nozzle prints a circle as big as the outlet).

With a layer height of 0.1 mm, the resolution is still too low (0,73 steps per cylinder).

This, of course, only does count with small objects meaning small distances between layer changes (retraction), because one path of extruded filament has to be long enough for a step in extrusion.

What you also have to take into account with the MMU (which I have) are the Bowden-Tubings. The and the long way of filament are buffering the steps as the equalize the pressure between on step and another. This also counts for the normal setup. The calculation is based on perfectly stiff filament with no buffer-effect.

What made a little difference to me is to turn retraction as low as possible. Just disabling retraction also enabled me to print small objects with a 0.25 mm nozzle. With retraction the success rate was extremely low.

So in my opintion you have two options:

1. Lower the retraction. Begin with zero, as it is not really needed here (comparing to an object with several distant print areas).

2. Print with a wider nozzle, perhaps 0.8 mm.

Oh and just because it is fun to explore the borders:

Lets take a layer height of 0.05 mm and a 0.15 mm nozzle (you can get from E3D). That is one of the lowest set-ups you still can easily afford.

When we now want a resolution of 1 step per cylinder (so one step to extrude 1 circle with 0.15 mm diameter and 0.05 mm height), we would need a resolution for the extruder of - hold your breath:

2722 steps per mm!

With the actual steppers and the bondtech, you would then need a gearbox with at least a 19,4:1 ratio. And the good news: Such NEMA 17 steppers with gearboxes exist! Yes, I am taking this as a possible project for the long run... 😎